Three-dimensional printing preparation method for dental bridge of dental implant

A technology of three-dimensional printing and dental bridge, which is applied in the field of denture processing, can solve the problems of large surface roughness at the interface between the dental bridge and the foundation pile, affecting the fit with the oral cavity, and affecting the installation accuracy, so as to achieve firm and reliable installation and high yield High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

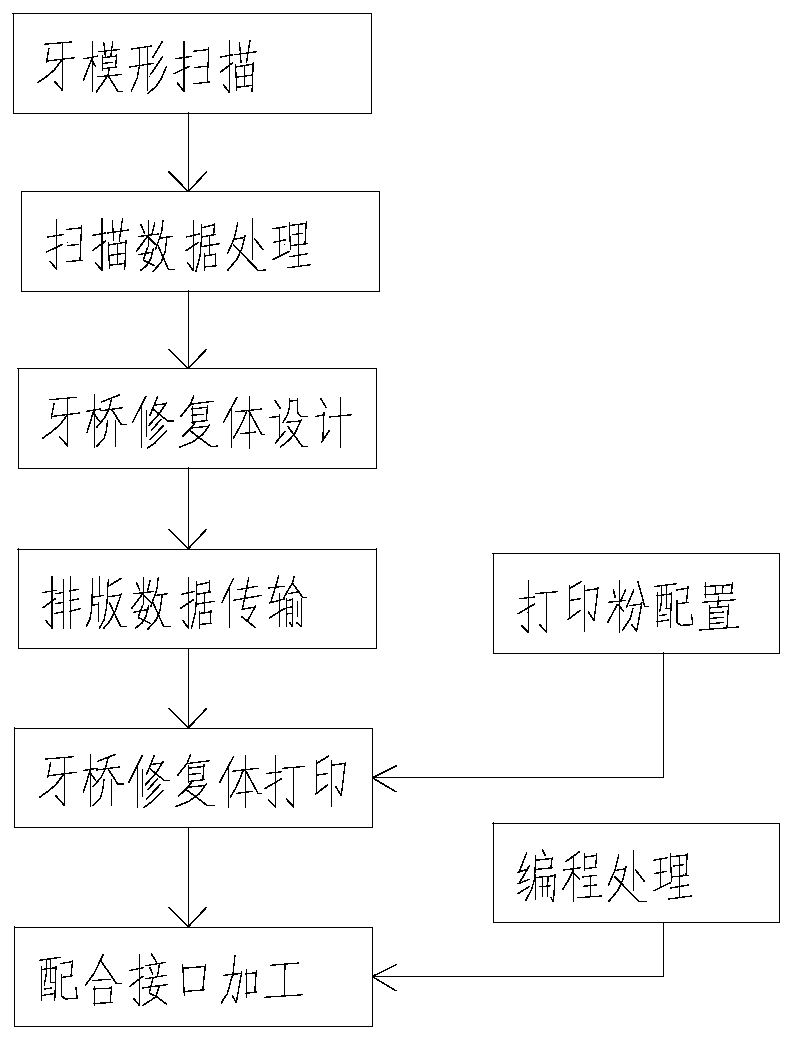

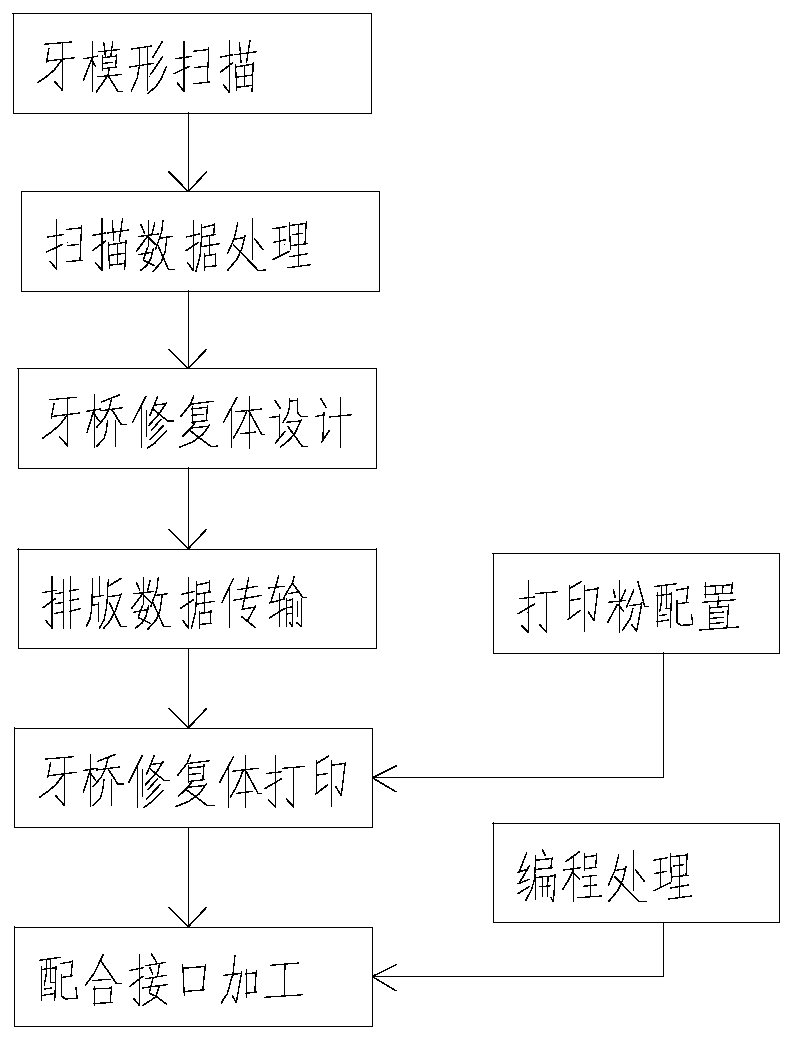

[0022] The three-dimensional printing preparation method of the implant bridge involved in this embodiment, its specific process includes tooth model shape scanning, scanning data processing, dental bridge restoration design, printing powder configuration, typesetting data transmission, dental bridge restoration printing, matching Interface processing seven steps:

[0023] (1) Dental mold shape scanning: use the existing technology to manufacture the plaster dental mold of the patient, computer-controlled optical scanner to scan the shape and size of the plaster model, collect the three-dimensional data of the optical impression of the plaster dental mold, and store the scanned data in the computer;

[0024] (2) Scanning data processing: use the computer system to process the three-dimensional data of the impression collected in step (1) and store in the computer, and calculate the retainer and connection of the dental bridge according to the way in place and the way of tooth a...

Embodiment 2

[0034] The three-dimensional printing preparation method of the implant bridge involved in this example, its specific process is the same as the seven steps in Example 1, and the components of the printing powder involved are 64:25:5:5:1 by weight. Proportional printing powder is especially suitable for the preparation of incisor bridges. The prepared incisor bridges have a bending strength of 80MPa, a compressive strength of 900MPa, a shrinkage rate of 0.4%, and are highly wear-resistant and corrosion-resistant.

Embodiment 3

[0036]The three-dimensional printing preparation method of the implant bridge involved in this example, its specific process is the same as the seven steps in Example 1, and the components of the printing powder involved are 69:24:2:2:1 by weight. Proportional printing powder is especially suitable for preparing molar bridges. The prepared incisor bridges have a bending strength of 105MPa, a compressive strength of 1100MPa, a shrinkage rate of 0.2%, and are highly wear-resistant and corrosion-resistant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com