Method and system for producing cold formed steel in continuous casting and rolling manner

A continuous casting and rolling, cold forming technology, applied in the direction of metal rolling, etc., can solve the problems of production speed and product quality, affect product quality, and numerous processes, and achieve the effects of improving efficiency, reducing heat loss, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, a short-flow, full-continuous production method is used to produce cold-formed steel.

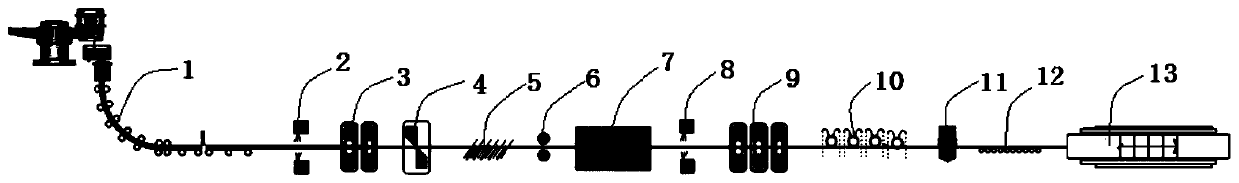

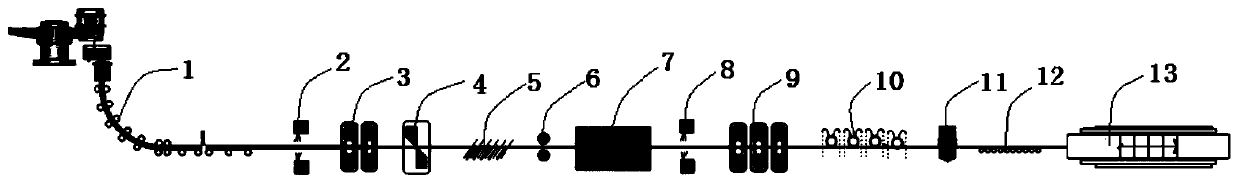

[0062] Such as figure 1 As shown, the production system includes a continuous casting machine 1, a high-pressure water rough descaling device 2, a rough rolling unit 3, a pendulum shear 4, a waste product pushing device 5, a first flying shear 6 (in this embodiment, a drum flying shear), an induction Heating furnace 7, high-pressure water descaling device 8, finishing rolling unit 9, post-rolling cooling device 10, second flying shear 11, air-cooling roller table 12, cold forming unit 13, each device is connected in sequence along the rolling axis.

[0063] In terms of mass percentage, the chemical composition of cold-formed steel raw materials is: C 0.11%, Mn 0.23%, Si 0.09%, P 0.01%, S 0.005%, Als 0.02%, and the balance is Fe and impurities.

[0064] The molten steel with the above composition is cast into a slab in the continuous casting machine 1, the continuou...

Embodiment 2

[0071] In this embodiment, a short-flow, full-continuous production method is used to produce cold-formed steel.

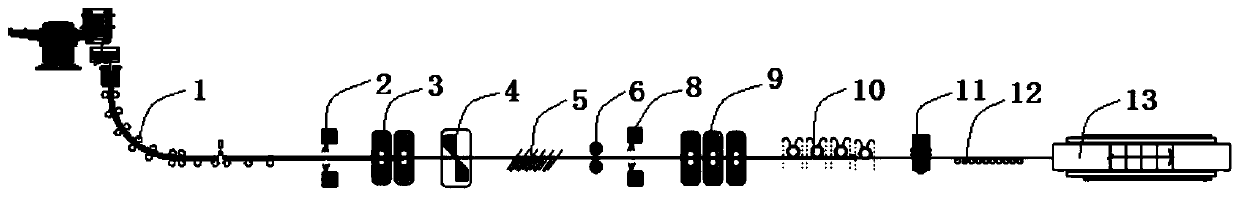

[0072] Such as figure 2 As shown, the production system includes a continuous casting machine 1, a high-pressure water rough descaling device 2, a rough rolling unit 3, a pendulum shear 4, a waste product pushing device 5, a first flying shear 6 (in this embodiment, a drum flying shear), a high-pressure The water polishing descaling device 8, the finishing rolling unit 9, the post-rolling cooling device 10, the second flying shear 11, the air cooling roller table 12, and the cold forming unit 13 are connected in sequence.

[0073] In terms of mass percentage, the chemical composition of cold-formed steel raw materials is: C 0.15%, Mn 1.26%, Si 0.14%, P 0.015%, S 0.01%, N 0.01%, Als 0.015%, and the balance is Fe and impurities.

[0074] The molten steel with the above composition was cast into billets in the continuous casting machine 1, the casting speed was sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com