Metal nano powder production system

A metal nanopowder and production system technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of easy adhesion of metal powder to the inner wall of the equipment, low sealing performance, and low recovery rate of metal powder. The effect of heat resistance, small space occupation, and easy replacement of crucibles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

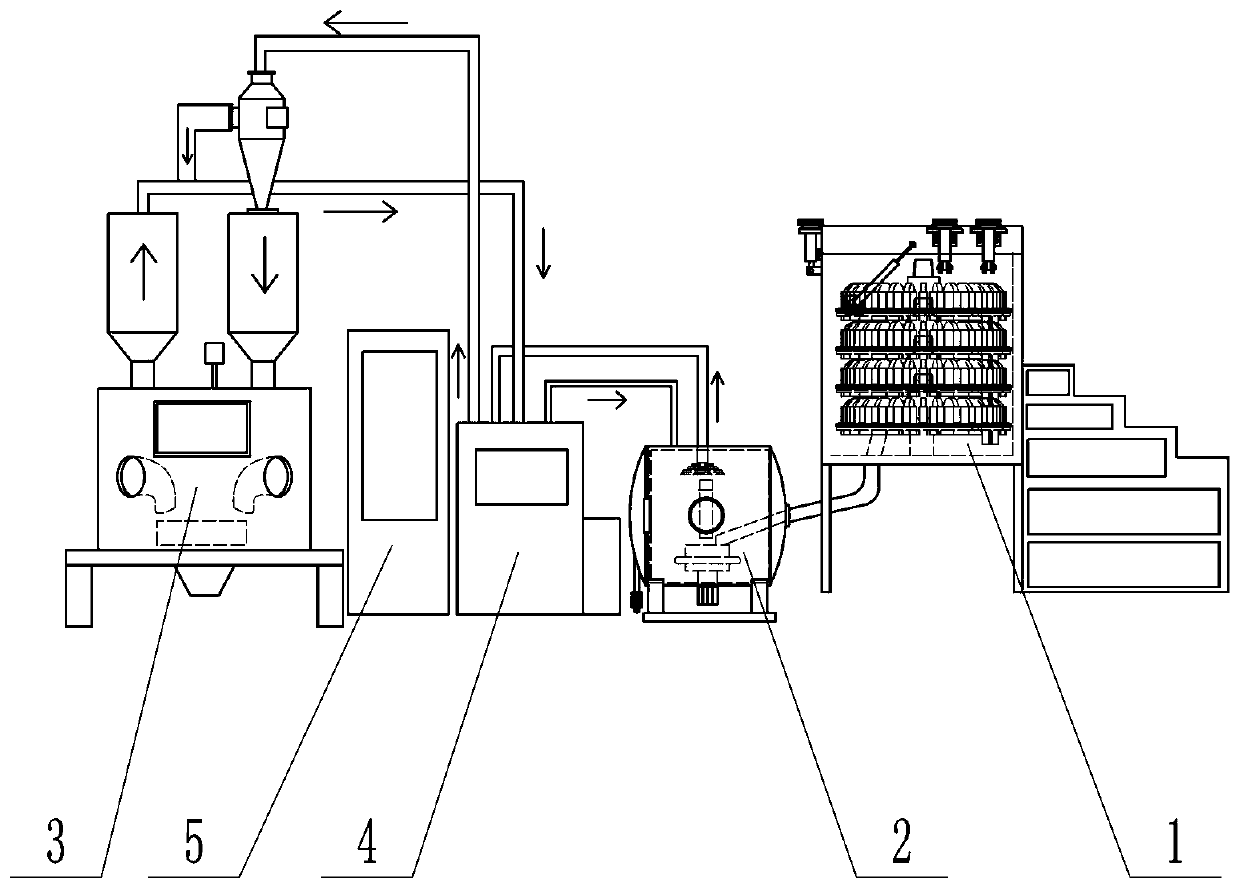

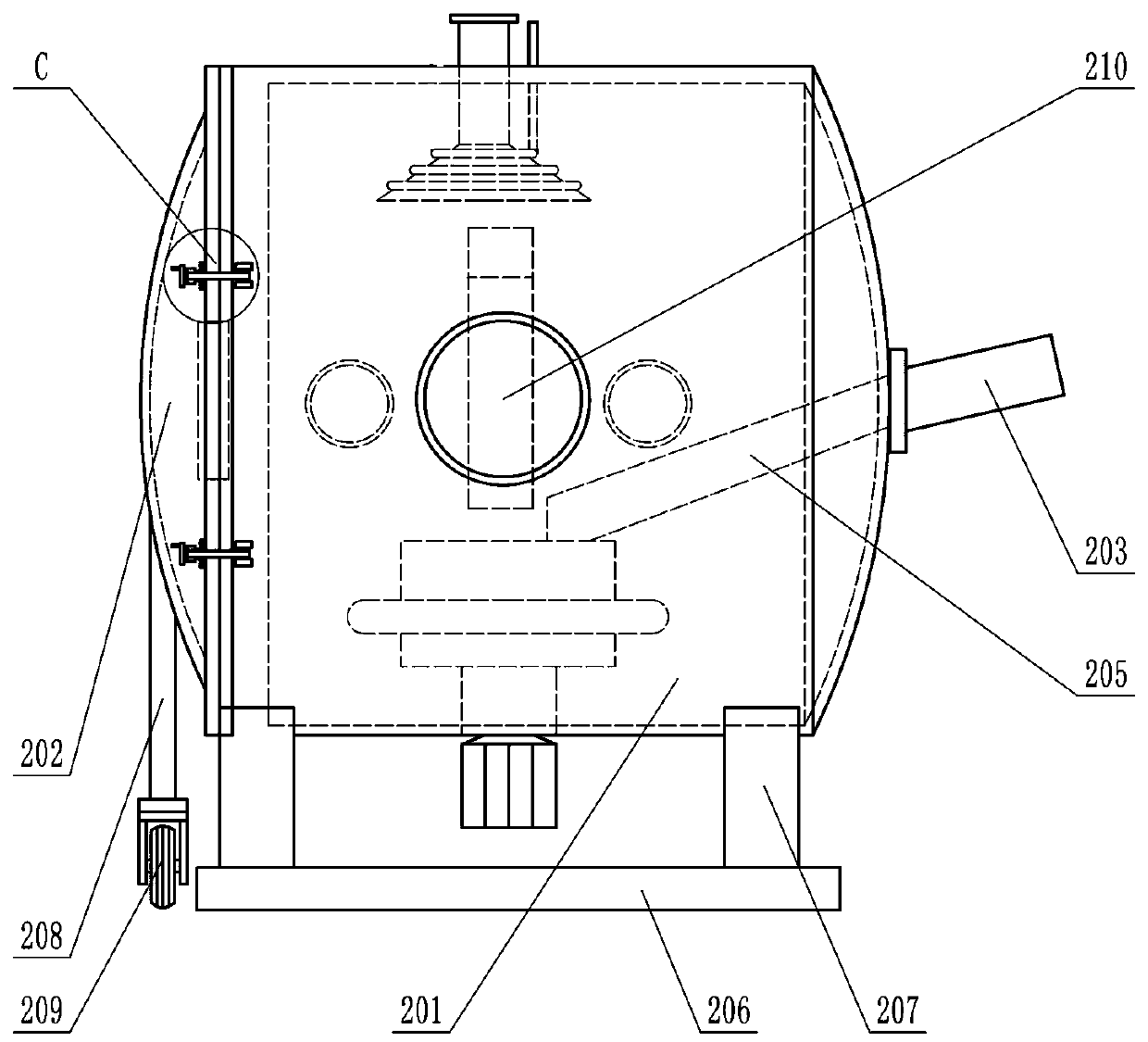

[0043] Such as Figure 1-18 As shown, a metal nanopowder production system includes a feeding device 1, a vacuum cavitation tank 2, a glove box 3, and a vacuum pump unit 4 connected in sequence through pipelines,

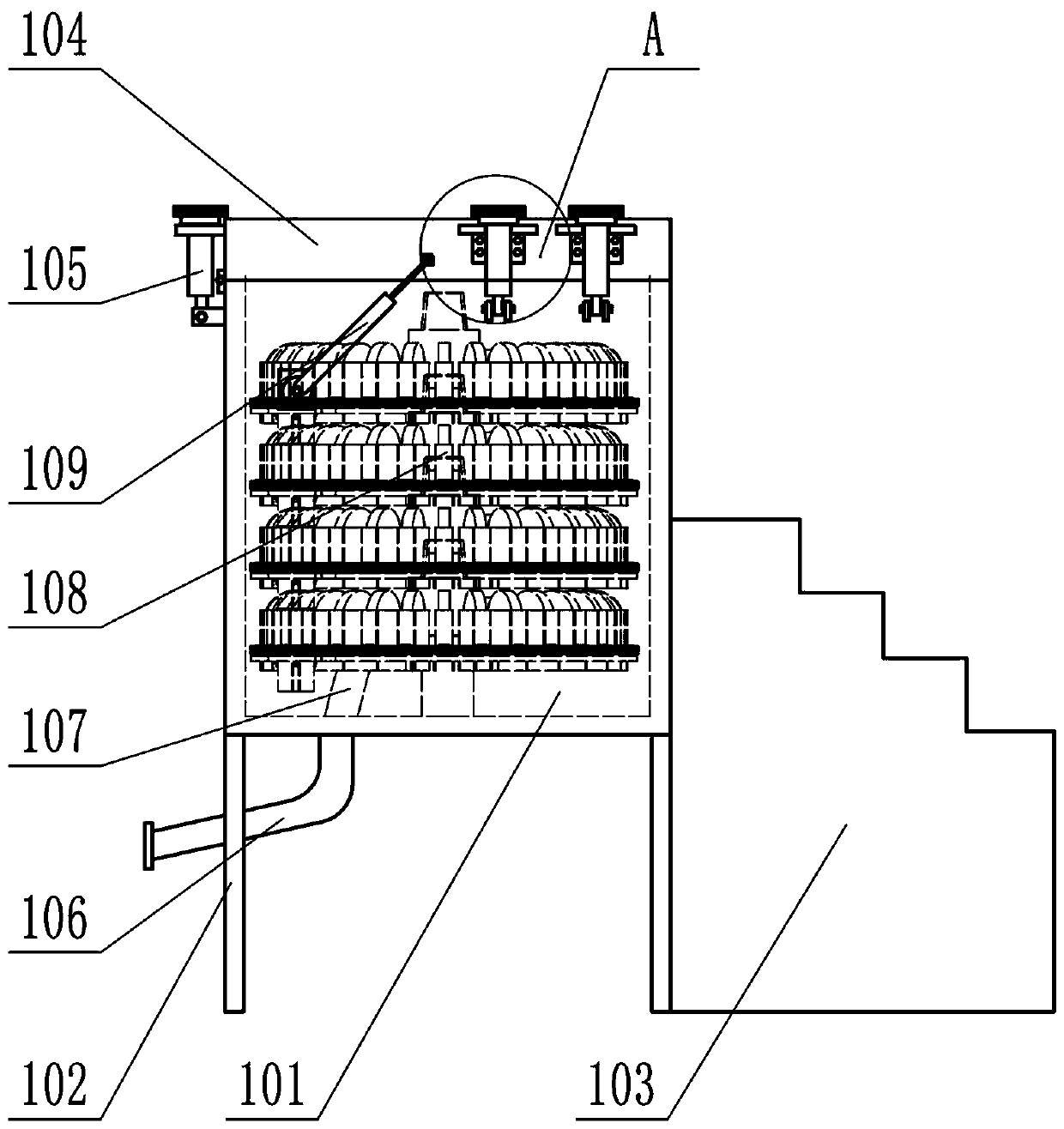

[0044] The feeding device 1 includes a box body 101, the top of the box body 101 is hinged and sealed with a box cover 104, the back of the box cover 104 is hinged with the box body 101 through a hinge, and the left and right sides of the box cover are symmetrically installed with drive cylinders 109 for opening the box cover One end of the drive cylinder 109 is hingedly installed on the outer wall of the box body, and the other end of the drive cylinder 109 is hingedly installed on the outer wall of the box cover. The drive cylinder between the box cover and the box body can reduce the labor intensity of the operator. To ensure the safety during the opening process of the box cover, the operator can supplement the production raw materials in the box through the ope...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap