Electrolytic manganese residue baking-free brick and preparation method thereof

A technology of electrolytic manganese slag and unburned bricks, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low utilization rate of electrolytic manganese slag, environmental pollution, etc., to reduce stockpiling, reduce Cost, Pollution Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take electrolytic manganese slag from a manganese mining company in Guangxi, mix electrolytic manganese slag, lime, water-quenched slag, and cement clinker in a ratio of 40:3:45:12, and then grind it with SM-500 test mill Cement M, then put cement M, electrolytic manganese slag, 5-10mm waste rock, and water into the mortar mixer according to the ratio of 15:29:40:16, and send it to the brick making machine after stirring for 3 minutes, using LM-02 Extrusion molding is carried out on a digital dynamometer, and a molding pressure of 20MPa is selected. After reaching the molding pressure, the pressure is stabilized for 3 minutes and then unloaded to make brick embryos. Send to the storage site, avoid direct sunlight and rain, and dry naturally for 7 days to become finished bricks. Its compressive strength was measured to be 21.08MPa, reaching the strength standard of unburned bricks.

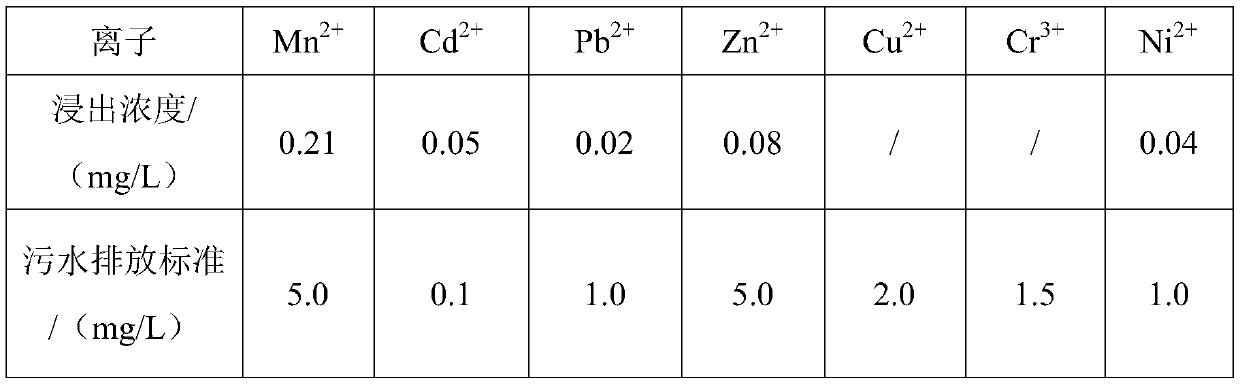

[0026] The non-burning brick was maintained for 28 days, and the heavy metal toxicity d...

Embodiment 2

[0030] Take electrolytic manganese slag from a manganese mining company in Guangxi, mix electrolytic manganese slag, lime, water-quenched slag, and cement clinker in a ratio of 40:3:45:12, and then grind it with SM-500 test mill Cement M, and then put cement M, electrolytic manganese slag, waste rock, and water into the mortar mixer according to the ratio of 15:36:35:14, and send it to the brick making machine after stirring for 3 minutes, using LM-02 digital Extrusion molding is carried out on a dynamometer, and a molding pressure of 20MPa is selected. After reaching the molding pressure, the pressure is stabilized for 3 minutes and then unloaded to make a brick embryo. Send to the storage site, avoid direct sunlight and rain, and dry naturally for 7 days to become finished bricks. Its compressive strength was measured to be 17.24MPa, reaching the strength standard of unburned bricks.

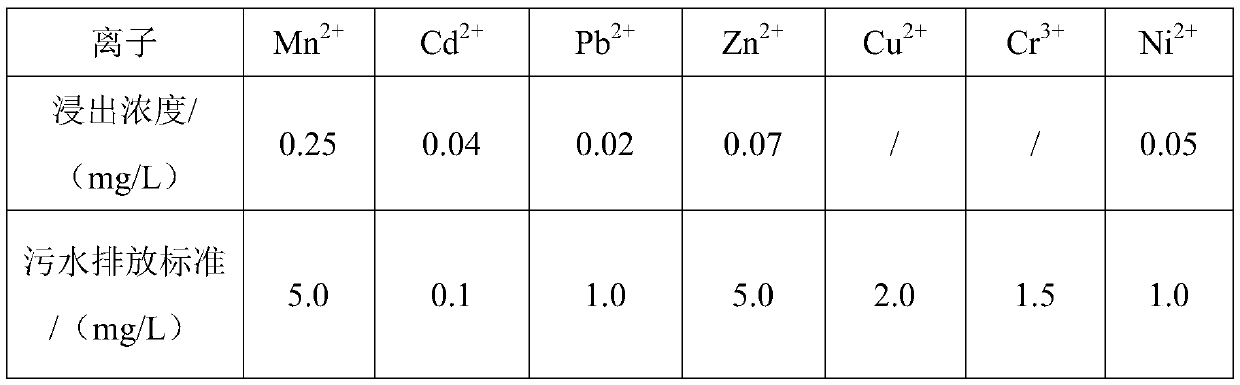

[0031] Unburned bricks for heavy metal toxicity detection and analysis

[0032]

[00...

Embodiment 3

[0035]Take electrolytic manganese slag from a manganese mining company in Guangxi, mix electrolytic manganese slag, lime, water-quenched slag, and cement clinker in a ratio of 40:3:45:12, and then grind it with SM-500 test mill Cementing agent MM, then put cementing agent MM, electrolytic manganese slag, waste rock and water into the mortar mixer according to the ratio of 15:39:30:16, and send it to the brick making machine after stirring for 3 minutes, using LM-02 digital Extrusion molding is carried out on a dynamometer, and a molding pressure of 20MPa is selected. After reaching the molding pressure, the pressure is stabilized for 3 minutes and then unloaded to make a brick embryo. Send to the storage site, avoid direct sunlight and rain, and dry naturally for 7 days to become finished bricks. The measured compressive strength is 12.89MPa, reaching the strength standard of unburned bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com