A kind of stevioside saponin decolorization resin and its preparation method and application

A decolorizing resin and stevioside technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of incomplete decolorization of stevioside saponin decolorization resin, low resin decolorization strength, poor anti-pollution ability, etc. , to achieve complete decolorization, low sugar loss and good resin strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

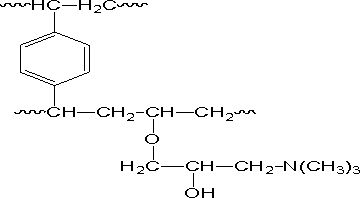

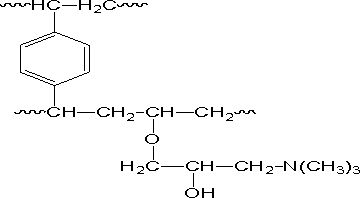

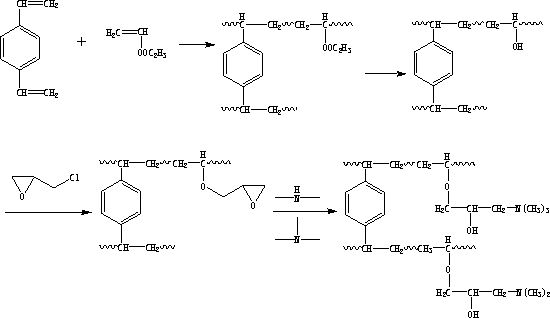

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of steviol saponin decolorizing resin, characterized in that, comprising the synthesis of resin skeleton and the functionalization of resin, and the steps are as follows:

[0036] a) Preparation of raw materials: proportion by mass as follows

[0037] water box

[0038] 100 parts deionized water

[0039] 0.5 servings of PVA

[0040] NaCl 1 part

[0041] oil phase

[0042] 1 part of divinylbenzene

[0043] 22 parts vinyl acetate

[0044] Butyl acetate, n-heptane, 6 parts in total

[0045] b) Suspension polymerization: the above water phase and oil phase were suspended and polymerized at 60°C for 24h to obtain white balls;

[0046] c) Hydrolyze the above white balls in an aqueous sodium hydroxide solution to obtain an intermediate ball; the mass fraction of the aqueous sodium hydroxide solution is 10%, the hydrolysis temperature is 50°C, and the hydrolysis time is 24h.

[0047] d) After the above-mentioned intermediate ball is fully swollen in...

Embodiment 2

[0050] A preparation method of steviol saponin decolorizing resin, characterized in that, comprising the synthesis of resin skeleton and the functionalization of resin, and the steps are as follows:

[0051] a) Preparation of raw materials: proportion by mass as follows

[0052] water box

[0053] 100 parts deionized water

[0054] 1 serving of PVA

[0055] 2 parts NaCl

[0056] oil phase

[0057] 2 parts of divinylbenzene

[0058] 23 parts vinyl acetate

[0059] 7 parts n-heptane

[0060] b) Suspension polymerization: the above water phase and oil phase were suspended and polymerized at 80°C for 18h to obtain white balls;

[0061] c) Hydrolyze the above white balls in an aqueous sodium hydroxide solution to obtain an intermediate ball; the mass fraction of the aqueous sodium hydroxide solution is 20%, the hydrolysis temperature is 70°C, and the hydrolysis time is 16h.

[0062] d) After the above-mentioned intermediate ball is fully swollen in dioxane, add 5 times the ...

Embodiment 3

[0065] A preparation method of steviol saponin decolorizing resin, characterized in that, comprising the synthesis of resin skeleton and the functionalization of resin, and the steps are as follows:

[0066] a) Preparation of raw materials: proportion by mass as follows

[0067] water box

[0068] 100 parts deionized water

[0069] 4 servings of gelatin

[0070] oil phase

[0071] 3 parts of divinylbenzene

[0072] 24 parts vinyl propionate

[0073] Methyl isobutyl methanol 6 parts

[0074] b) Suspension polymerization: suspend the above water phase and oil phase at 100°C for 10 hours to prepare white balls;

[0075] c) The above-mentioned white balls were hydrolyzed in sodium hydroxide aqueous solution to obtain intermediate balls; the mass fraction of sodium hydroxide aqueous solution was 30%, the hydrolysis temperature was 100°C, and the hydrolysis time was 8 hours.

[0076] d) After the above-mentioned intermediate ball is fully swollen in methanol, add 10 times of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com