Low-temperature rapid sealing material for high gas coal mine and preparation method thereof

A technology for gas and coal mines, which is applied in the field of low-temperature fast sealing materials for high-gas coal mines and their preparation, can solve the problems of failure to effectively control the reaction temperature of the foaming process, hidden dangers of mine safety, and smoke from the foam, so as to avoid the accumulation of reaction heat. , good airtightness, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

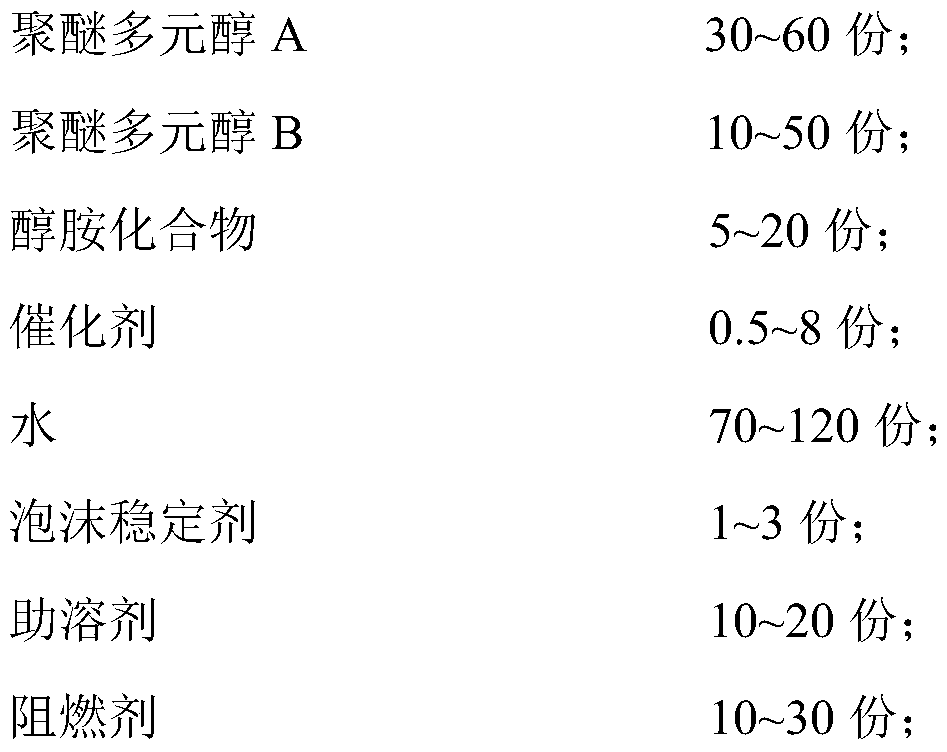

[0029] A component is composed as follows, in parts by mass:

[0030]

[0031]

[0032] Group B is PM-200.

[0033] Add polyether polyol EP-330N, polyether polyol MN-3050, and triethanolamine into the mixing tank and stir evenly, then add catalyst Polycat5, catalyst Polycat41, catalyst Dabco T-12, water, foam stabilizer AK- 8872, co-solvent OP-10, co-solvent TX-10, flame retardant TCPP, continue stirring at room temperature to obtain component A;

[0034] Mix and stir components A and B at a volume ratio of 1:1 to obtain a low-temperature rapid sealing material for high-gas coal mines.

Embodiment 2

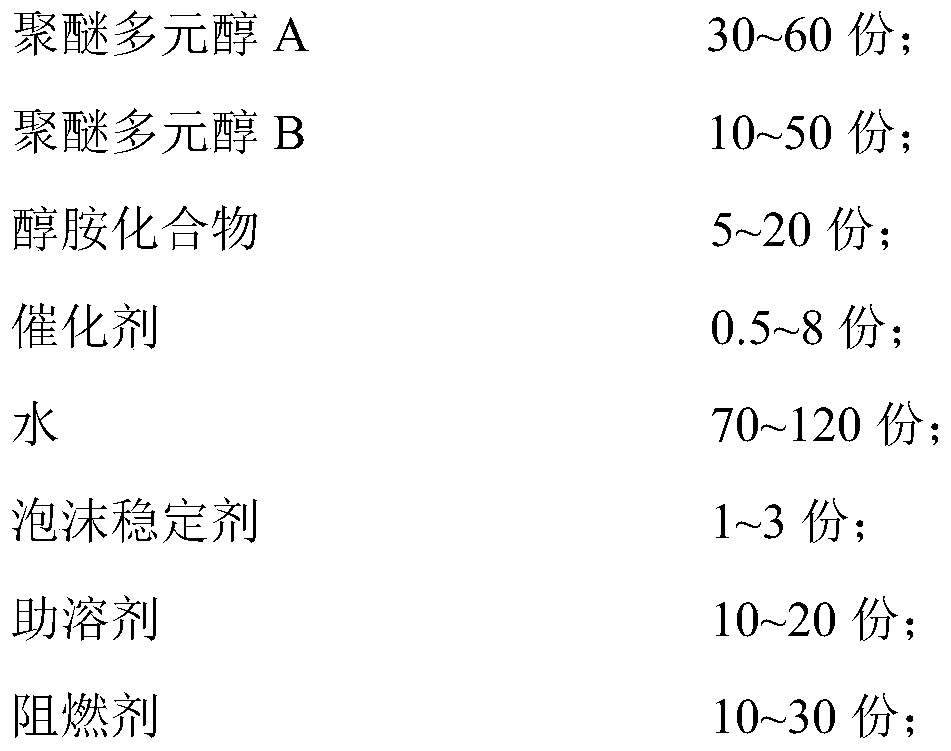

[0036] A component is composed as follows, in parts by mass:

[0037]

[0038] Group B is PM-200.

[0039] Add polyether polyol EP-330N, polyether polyol MN-3050, and triethanolamine into the mixing tank and stir evenly, then add catalyst Polycat5, catalyst Polycat41, catalyst Dabco T-12, water, foam stabilizer AK- 8872, co-solvent OP-10, co-solvent TX-10, flame retardant TCPP, continue stirring at room temperature to obtain component A;

[0040] Mix and stir components A and B at a volume ratio of 1:1.2 to obtain a low-temperature rapid sealing material for high-gas coal mines.

Embodiment 3

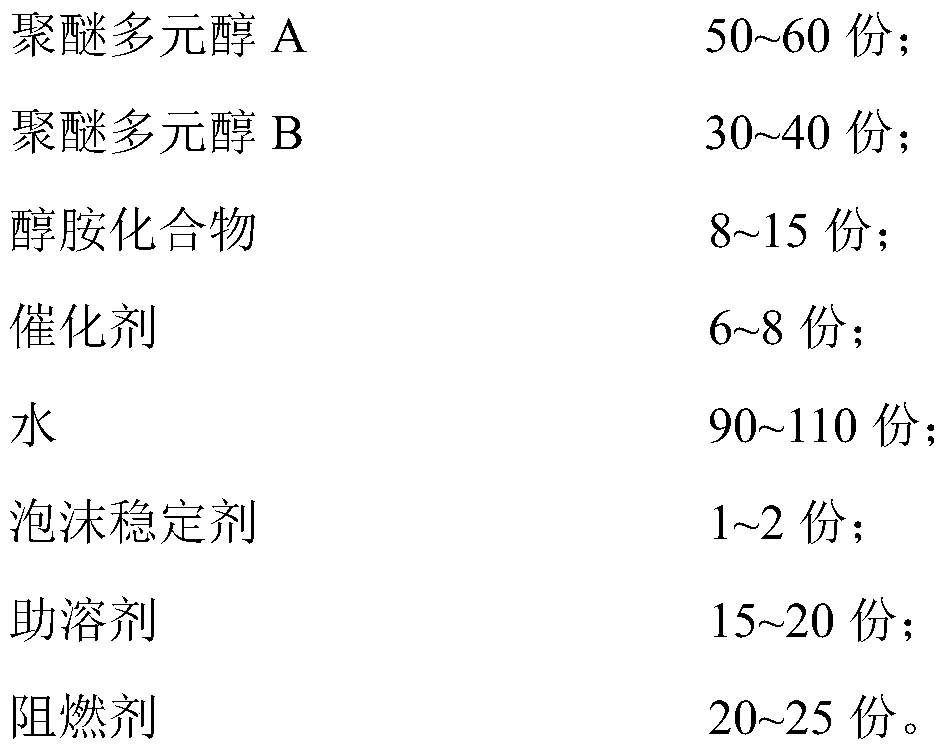

[0042] A component is composed as follows, in parts by mass:

[0043]

[0044] Group B is PM-200.

[0045] Add polyether polyol EP-330N, polyether polyol MN-3050, and triethanolamine into the mixing tank and stir evenly, then add catalyst Polycat 5, catalyst Polycat 41, catalyst Dabco T-12, water, and foam stabilizer in sequence AK-8872, co-solvent OP-10, flame retardant TCPP, flame retardant DMMP, continue stirring at room temperature to obtain component A;

[0046] Mix and stir components A and B at a volume ratio of 1:1.5 to obtain a low-temperature rapid sealing material for high-gas coal mines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com