A kind of high soft flame retardant fabric

A flame-retardant fabric, soft technology, applied in viscose-made rayon, yarn, textiles and papermaking, etc., can solve the problem of fabric softness, poor air permeability, reduced wearing comfort for wearers, and limited use of fabrics and other problems, to achieve the effect of improving softness and flame retardant properties, improving light fastness, maintaining hand feel and soft comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

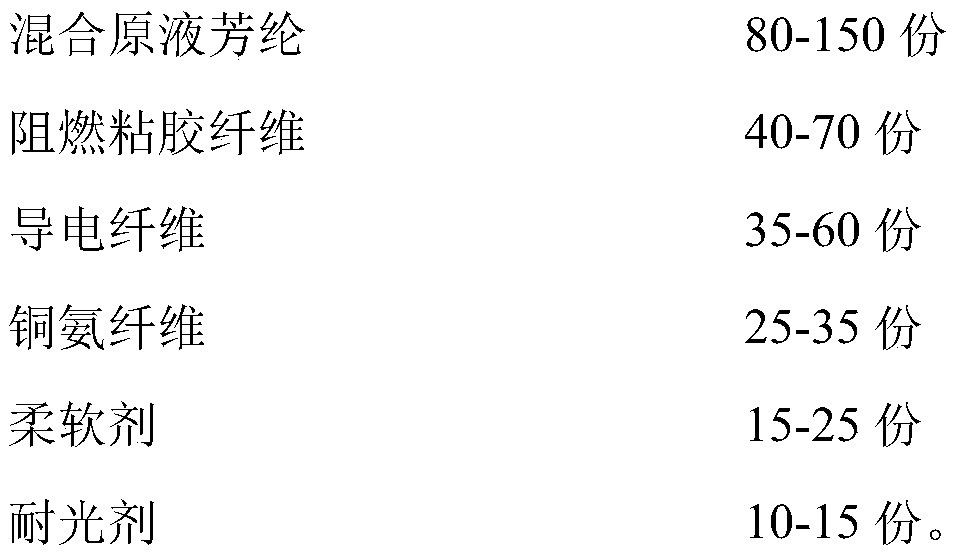

[0041] Embodiment 1: A kind of highly flexible flame-retardant fabric, comprises the following components by weight:

[0042]

[0043] in:

[0044] The mixed dope aramid is made by blending para-aramid and meta-aramid with a mass ratio of 1:18;

[0045] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0046] The softener is a quaternary ammonium salt cationic softener;

[0047] The light-resistant agent is rutile titanium dioxide with a particle size range of 30-50nm.

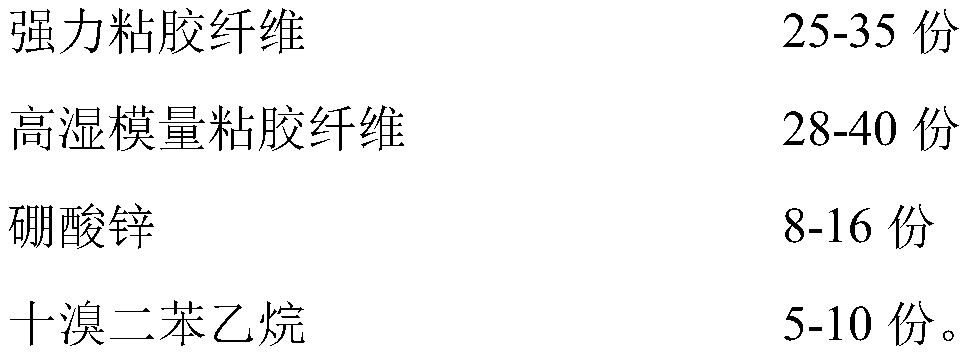

[0048] The flame retardant viscose fiber comprises the following components by weight:

[0049]

[0050] The preparation steps of flame-retardant viscose fiber are as follows:

[0051] S1. The strong type viscose pulp and the high wet modulus type viscose pulp are sequentially mixed and fed, soaked, squeezed, crushed, aged, yellowed and ground to obtain a mixed viscose fiber precursor;

[0052] S2. Add zinc borate and decabromodiphenylethane into a ball mill, mix and grin...

Embodiment 2

[0054] Embodiment 2: A kind of highly flexible flame-retardant fabric, comprises the following components by weight:

[0055]

[0056] in:

[0057] The mixed dope aramid is made by blending para-aramid and meta-aramid with a mass ratio of 1:19;

[0058] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0059] The softener is a quaternary ammonium salt cationic softener;

[0060] The light-resistant agent is rutile titanium dioxide with a particle size range of 30-50nm.

[0061] The flame retardant viscose fiber comprises the following components by weight:

[0062]

[0063] The preparation steps of flame-retardant viscose fiber are as follows:

[0064] S1. The strong type viscose pulp and the high wet modulus type viscose pulp are sequentially mixed and fed, soaked, squeezed, crushed, aged, yellowed and ground to obtain a mixed viscose fiber precursor;

[0065] S2. Add zinc borate and decabromodiphenylethane into a ball mill, mix and gr...

Embodiment 3

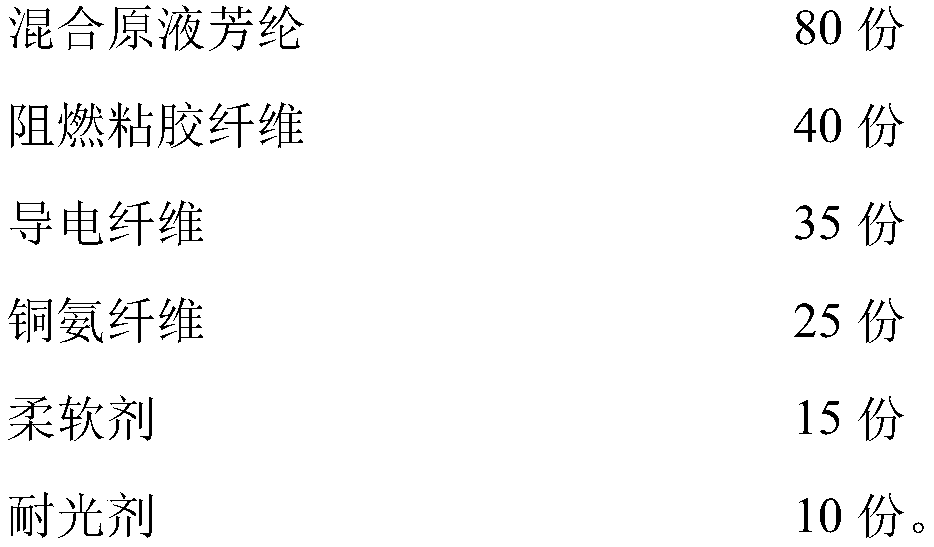

[0067] Embodiment 3: A kind of highly flexible flame-retardant fabric, comprises the following components by weight:

[0068]

[0069] in:

[0070] The mixed dope aramid is made by blending para-aramid and meta-aramid with a mass ratio of 1:20;

[0071] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0072] The softener is a quaternary ammonium salt cationic softener;

[0073] The light-resistant agent is rutile titanium dioxide with a particle size range of 30-50nm.

[0074] The flame retardant viscose fiber comprises the following components by weight:

[0075]

[0076] The preparation steps of flame-retardant viscose fiber are as follows:

[0077] S1. The strong type viscose pulp and the high wet modulus type viscose pulp are sequentially mixed and fed, soaked, squeezed, crushed, aged, yellowed and ground to obtain a mixed viscose fiber precursor;

[0078] S2. Add zinc borate and decabromodiphenylethane into a ball mill, mix and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com