Regenerated cotton yarn and preparation method thereof

A technology of regenerated cotton yarn and cotton yarn, which is applied in the direction of yarn, biochemical fiber treatment, fiber type, etc., can solve the problems of easy disappearance of drug powder smell, poor anti-ultraviolet performance, and unsustainable physiotherapy effect, so as to improve the durability of physiotherapy, prevent Enhanced UV resistance and good UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

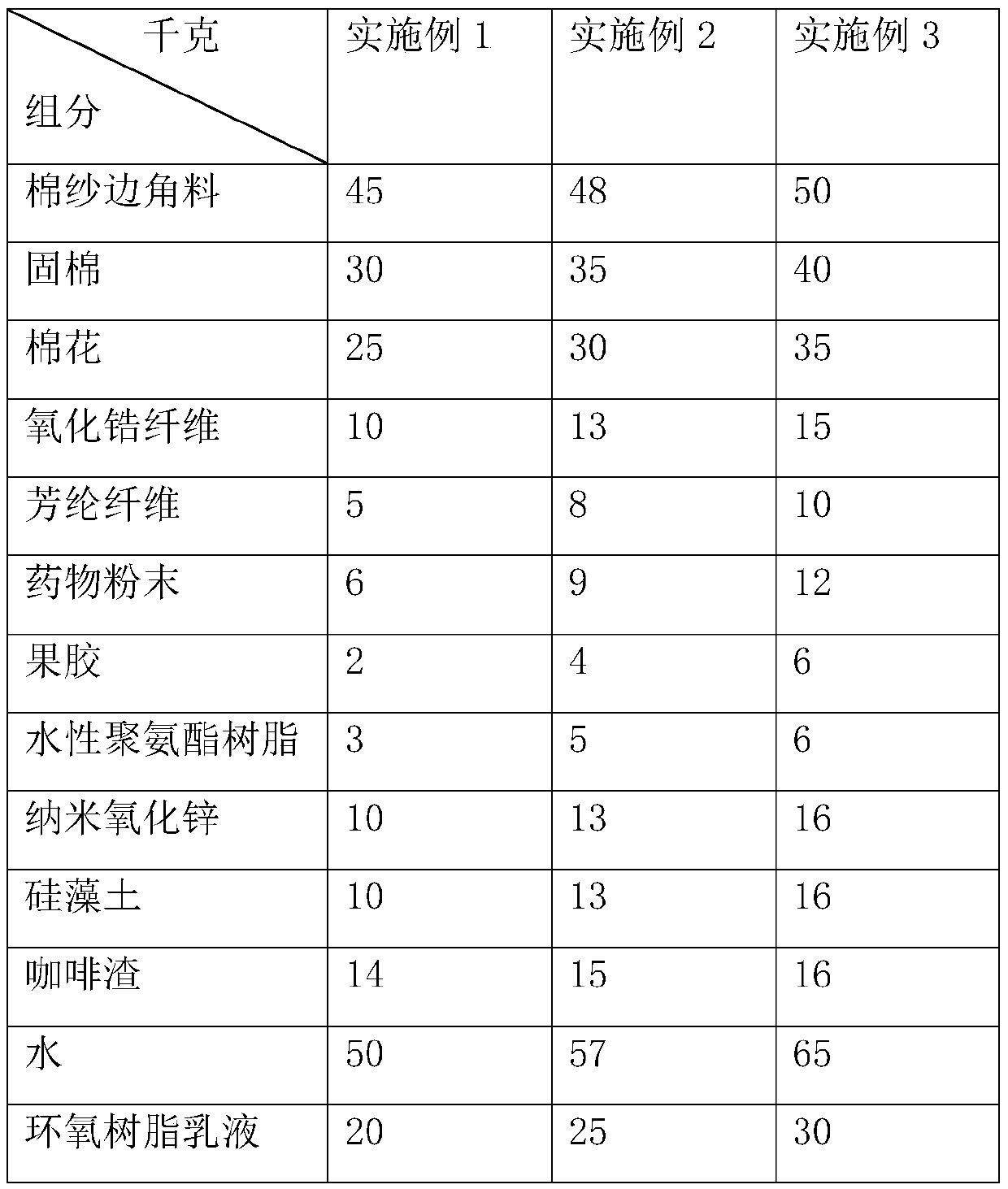

preparation example 1-3

[0036] In the preparation example 1-3, the coffee grounds are selected from the non-edible activated carbon coffee grounds sold by Shanghai Dandie Food Co., Ltd., the chitosan is selected from the chitosan sold by Henan Xihe Chemical Co., Ltd., and the bamboo fiber is selected from XH-0148. The article number sold from Hangzhou Jiekang Bamboo Fiber Products Co., Ltd. is the bamboo fiber of 002, and the nano-titanium dioxide colloid is selected from the model A212 nano-titanium dioxide colloid sold by Jingjiang Tonggao Chemical Co., Ltd.

preparation example 1

[0037] Preparation example 1: put 20kg of coffee grounds at 160°C to calcinate for 1 hour, take it out and mix it with 5kg of chitosan and 6kg of bamboo fiber, add 12kg of nano-titanium dioxide colloid, mix it evenly, dry it and grind it to a particle size of 10nm.

preparation example 2

[0038] Preparation example 2: 25kg of coffee grounds were calcined at 170°C for 1.5h, taken out, mixed evenly with 7kg of chitosan and 8kg of bamboo fiber, added 14kg of nano-titanium dioxide colloid, mixed evenly, dried and ground to a particle size of 15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com