Volatile organic compound (VOC) adsorption and tail hydrogen safe treatment device and method for purge gas of aromatic hydrogenation system

A technology for safe treatment and release of gas, applied in gas treatment, chemical instruments and methods, combustion methods, etc., can solve problems such as poor safety, achieve the effect of preventing explosion, safe and reliable control and operation methods, and ensuring overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

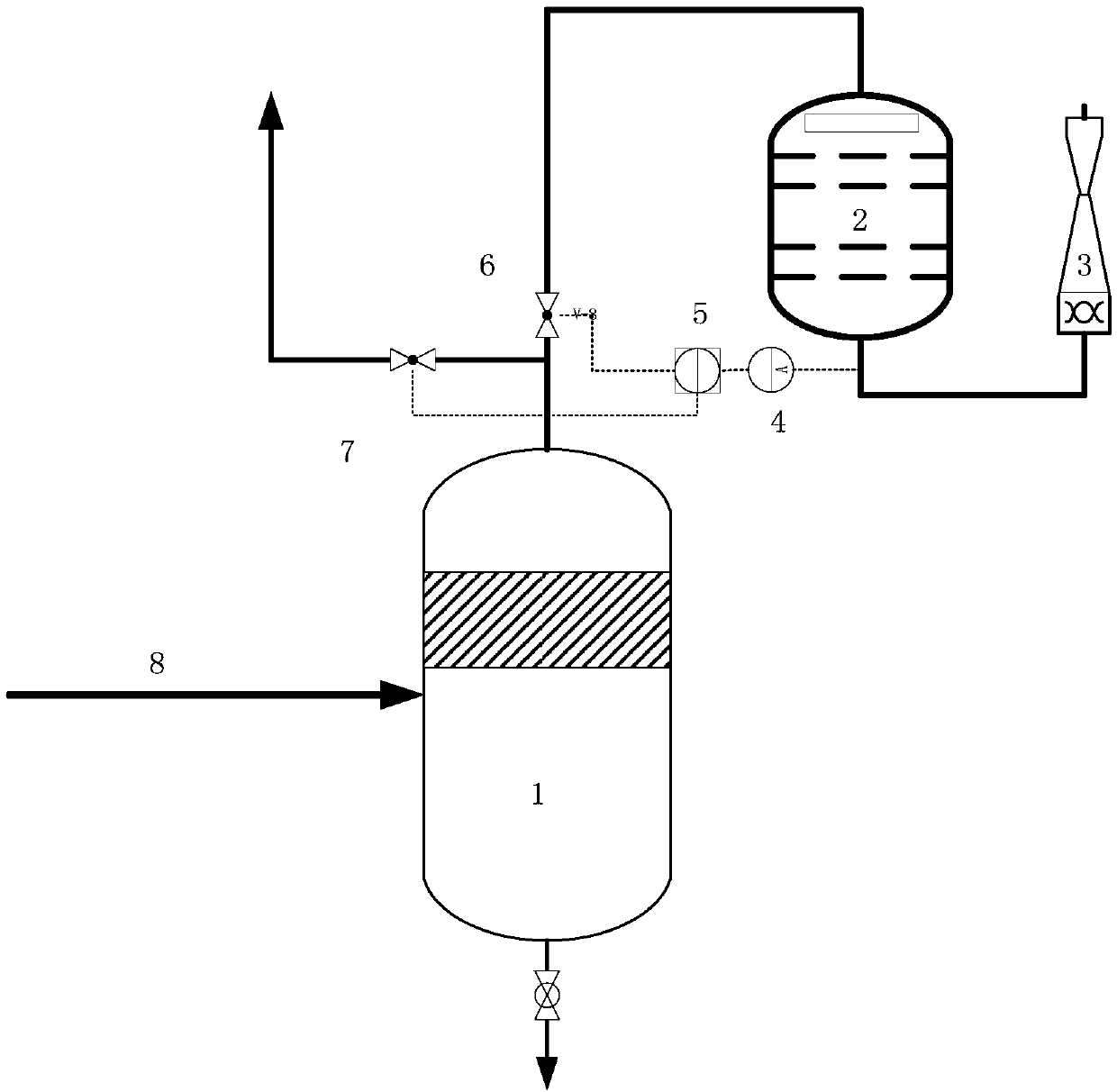

[0017] A method for VOC adsorption and tail hydrogen safety treatment of purge gas from an aromatics hydrogenation system, such as figure 1 As shown, after the exhaust gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters the VOC adsorber, and the absorbed exhaust gas enters the hydrogen processor, and finally discharges up to the standard; the activated carbon fiber in the VOC adsorber absorbs the VOC For the aromatics in the gas release, the hydrogen processor adopts a Venturi design, and there is a flame-retardant wire mesh inside. When the gas is discharged, the air is sucked in through the pressure, and a mixing zone is formed at the outlet section. The outlet of the hydrogen processor is equipped with an ignition head, which automatically Ignite to remove the hydrogen.

[0018] The feed inlet of the VOC adsorber is equipped with a feed distributor. The distributor adopts a sieve structure, and the total area of the sie...

Embodiment 2

[0021] A method for VOC adsorption and tail hydrogen safety treatment of purge gas from an aromatics hydrogenation system, such as figure 1 As shown, after the purge gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters the VOC adsorber, and the purge gas after the adsorption enters the hydrogen processor, and finally discharges up to the standard; there are activated carbon fibers in the VOC adsorber, which absorb The aromatics in the exhaust gas, the hydrogen processor adopts a Venturi design, and there is a flame-retardant screen inside. When the gas is discharged, the air is sucked in through the pressure, and a mixing zone is formed at the outlet section. The outlet of the hydrogen processor is equipped with an ignition head. Automatically ignites and removes the hydrogen.

[0022] The feed inlet of the VOC adsorber is equipped with a feed distributor. The distributor adopts a sieve structure, and the total area of the ...

Embodiment 3

[0025] A method for VOC adsorption and tail hydrogen safety treatment of purge gas from an aromatics hydrogenation system, such as figure 1 As shown, after the purge gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters the VOC adsorber, and the purge gas after the adsorption enters the hydrogen processor, and finally discharges up to the standard; there are activated carbon fibers in the VOC adsorber, which absorb The aromatics in the exhaust gas, the hydrogen processor adopts a Venturi design, and there is a flame-retardant screen inside. When the gas is discharged, the air is sucked in through the pressure, and a mixing zone is formed at the outlet section. The outlet of the hydrogen processor is equipped with an ignition head. Automatically ignites and removes the hydrogen.

[0026] The feed inlet of the VOC adsorber is equipped with a feed distributor. The distributor adopts a sieve structure, and the total area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com