Preparation method of spherical iron-based powder

A powder and spherical technology, applied in the field of the preparation of spherical ferrite-based powder, can solve the problems such as the inability to effectively control the amount of intermetallic compounds, reduce the high-temperature mechanical properties of materials, and reduce intermetallic compounds, and achieve controllable product composition, The effect of strong designability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

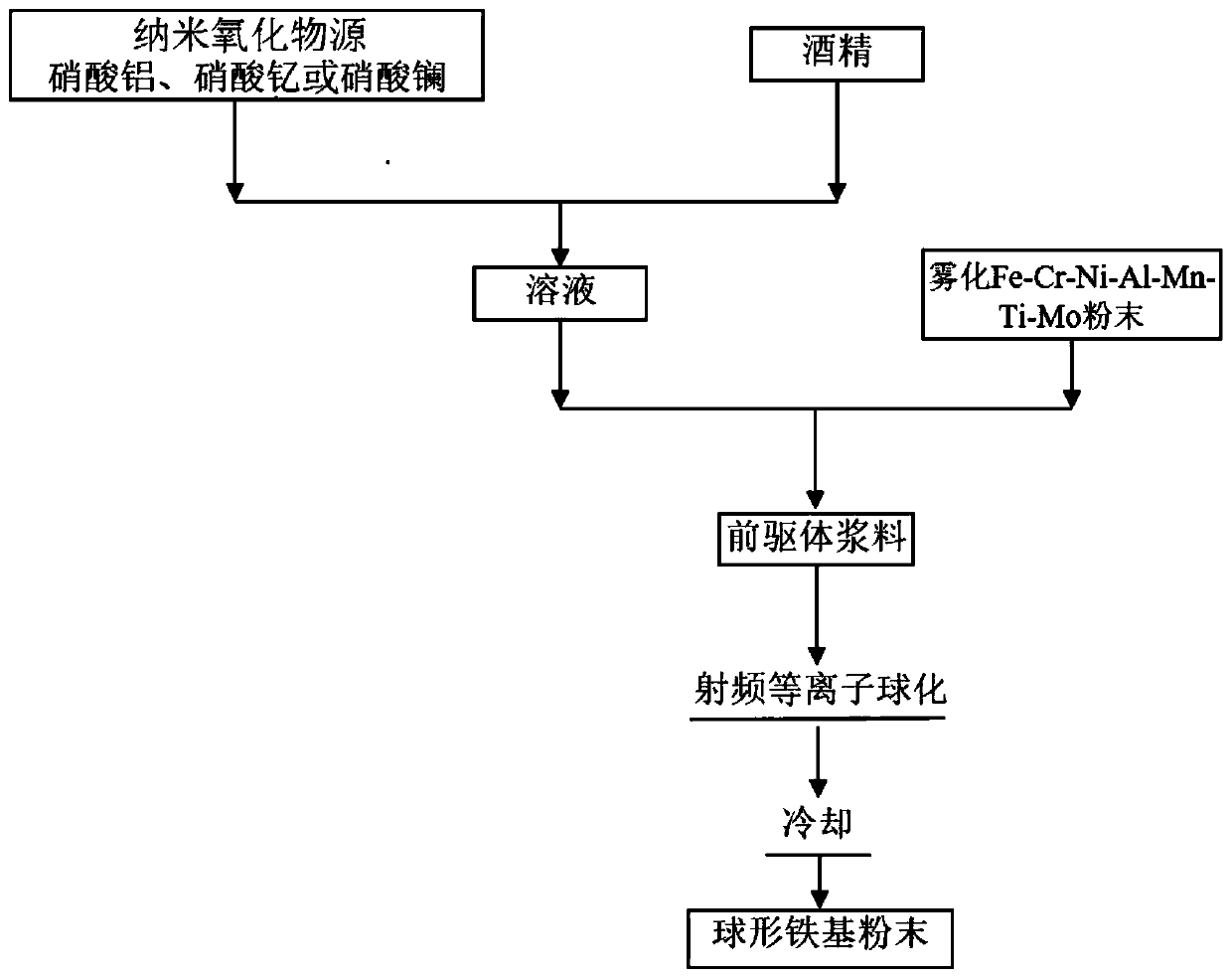

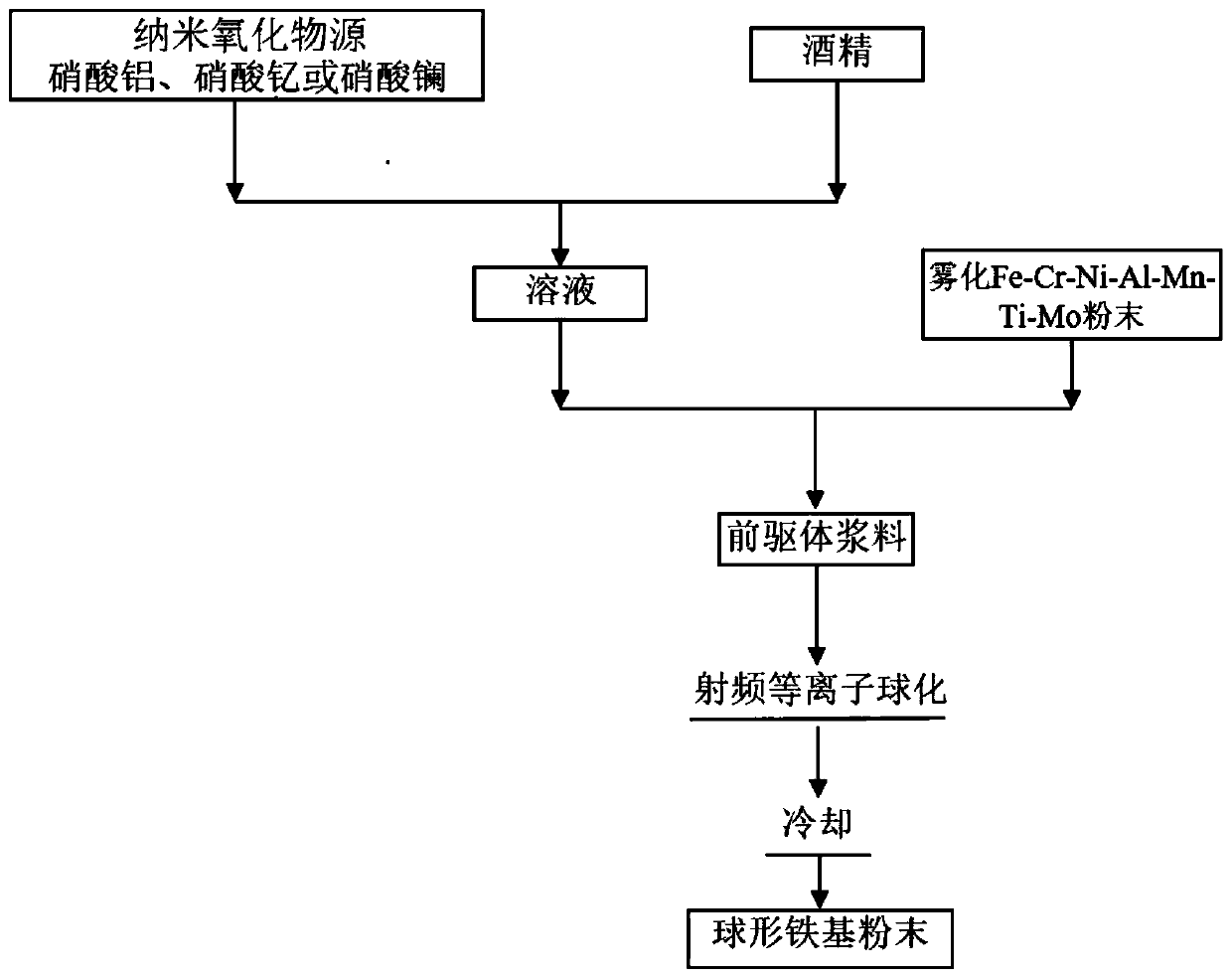

[0027] Such as figure 1 Shown, a kind of preparation method of spherical ferrite base powder of the present invention, described method comprises the following steps,

[0028] Configuration of S1 precursor slurry: dissolve the nano-oxide source in an appropriate amount of solvent to obtain a transparent solution, add the aerosolized powder into the transparent solution and soak it completely, and use a mixer to mix 0.5 at a speed of 20-60 rpm -4 hours to obtain a homogeneously mixed precursor slurry;

[0029] S2 Preparation of intermetallic compound and nano-oxide co-reinforced spherical ferrite-based powder products: the obtained precursor slurry is prepared by radio frequency plasma spheroidization technology to obtain spherical ferrite-based powder, the spherical ferrite-based powder The average particle size of the oxide dispersed phase in the middle is ≤15nm.

[0030] According to an embodiment of the present disclosure, the solvent in S1 is alcohol.

[0031] According...

Embodiment 1

[0041] Fe-8wt.%Cr-5wt.%Ni-1wt.%Al-2wt.%Mn-1wt.%Ti-2wt.%Mo-1wt.%Al 2 o 3 Preparation of spherical ferrite-based powders co-reinforced by intermetallic compounds and nano-oxides

[0042] The atomized powder and aluminum nitrate (Al(NO 3 ) 3 9H 2 O) Weigh it with a mass ratio of 13.464:1 for later use.

[0043] Dissolve the weighed aluminum nitrate in an appropriate amount of alcohol, and stir in a container to form a transparent solution. Add atomized powder and appropriate amount of alcohol into the solution evenly until the alloy powder is just wetted by alcohol. Next, a mixer was used to mix for 2 hours at a speed of 40 rpm to obtain a precursor slurry.

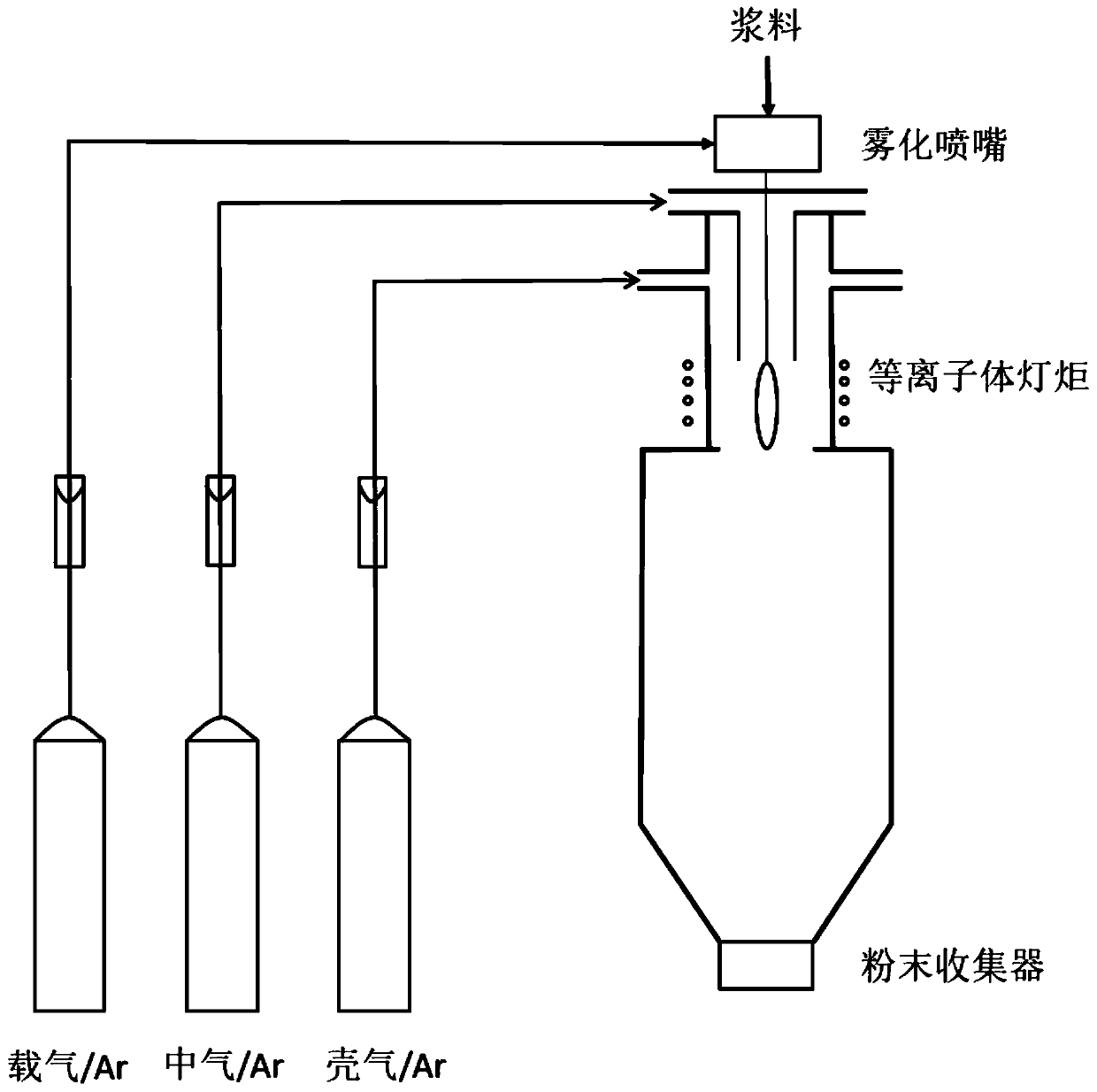

[0044] During the radio frequency plasma spheroidization process, the negative pressure is 7500Pa; the middle gas is argon, and the flow rate of the middle gas is 25L / min; the shell gas is argon, and the flow rate of the shell gas is 70L / min; The gas sprays the precursor solution into the plasma arc through the feedin...

Embodiment 2

[0046] Fe-12wt.%Cr-6wt.%Ni-1.5wt.%Al-3wt.%Mn-1.5wt.%Ti-2wt.%Mo-0.6wt.%Y 2 o 3 Preparation of spherical ferrite-based powders co-reinforced by intermetallic compounds and nano-oxides

[0047] The atomized powder and yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) Weigh it with a mass ratio of 48.878:1 for later use.

[0048] First, dissolve the weighed yttrium nitrate in an appropriate amount of alcohol, and stir in a container to form a transparent solution. Add atomized powder and appropriate amount of alcohol into the solution evenly until the alloy powder is just wetted by alcohol. Next, a mixer was used to mix for 4 hours at a speed of 30 rpm to obtain a precursor slurry. During the radio frequency plasma spheroidization process, the negative pressure is 7800Pa; the middle gas is argon, and the flow rate of the middle gas is 20L / min; the shell gas is argon, and the flow rate of the shell gas is 75L / min; the carrier gas is 6L / min The gas sprays the precursor solution into the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com