Composite doped bismuth ferrite-barium titanate binary lead-free ferroelectric ceramic material, preparation method and application thereof

A technology of composite doping and ferroelectric ceramics, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, etc., can solve the problems of poor ferroelectric performance and leakage of BFO ceramics, and achieve the effect of reducing volatilization and stabilizing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

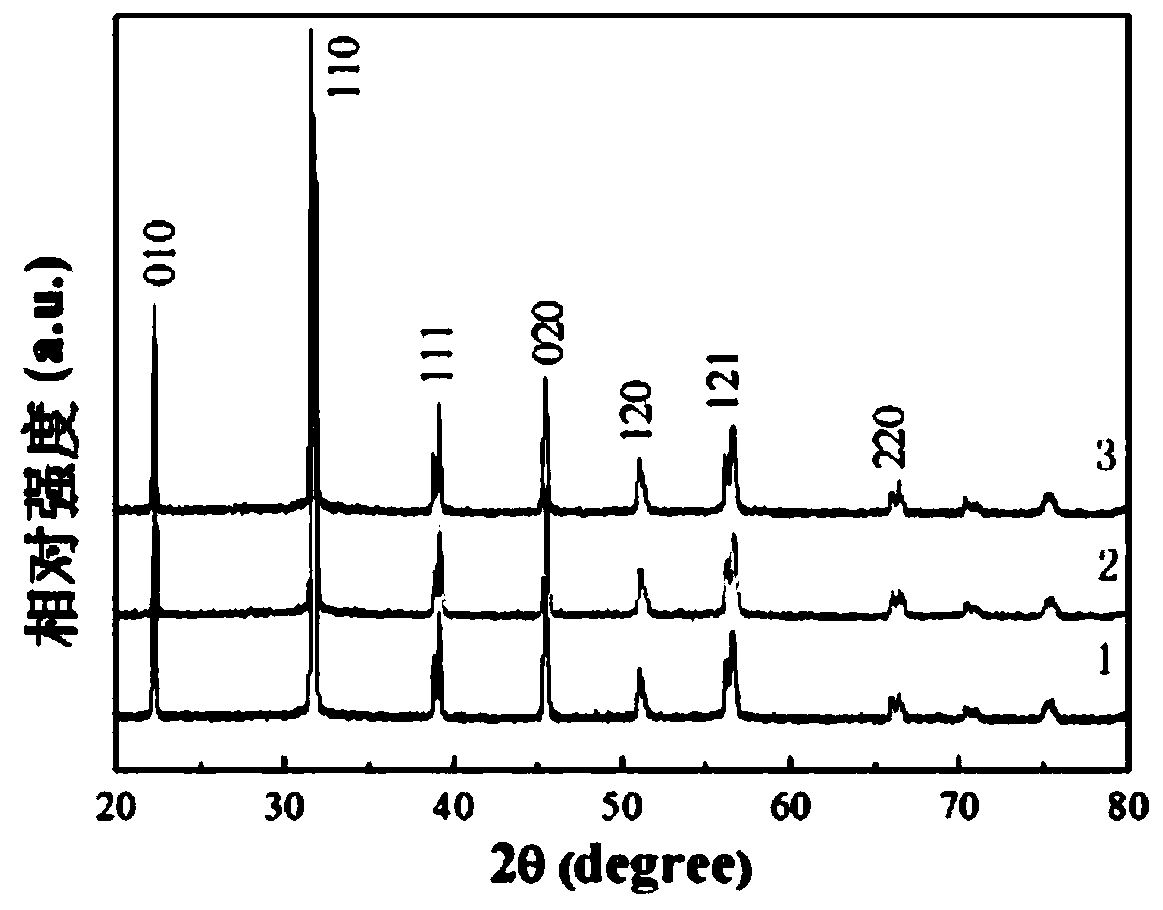

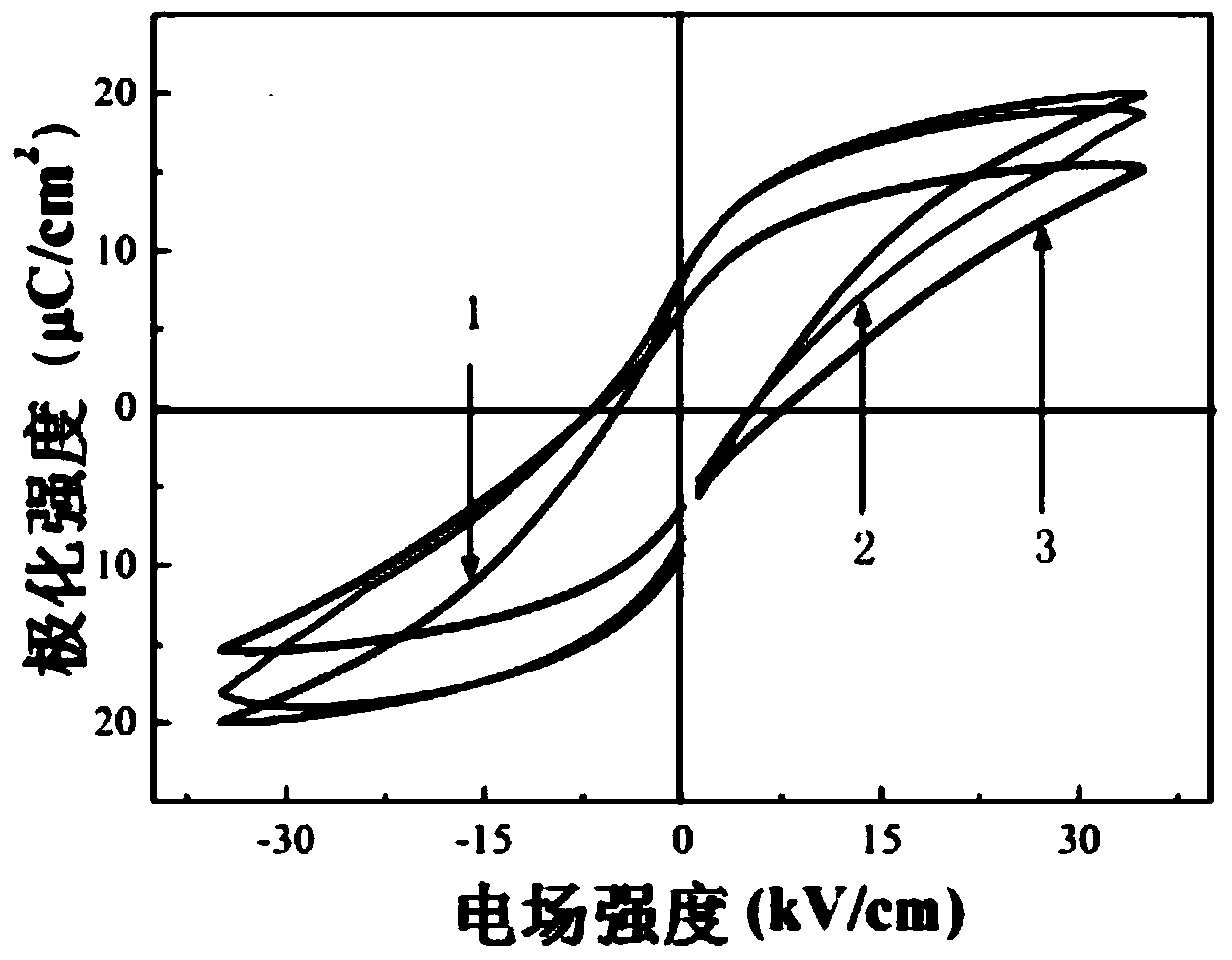

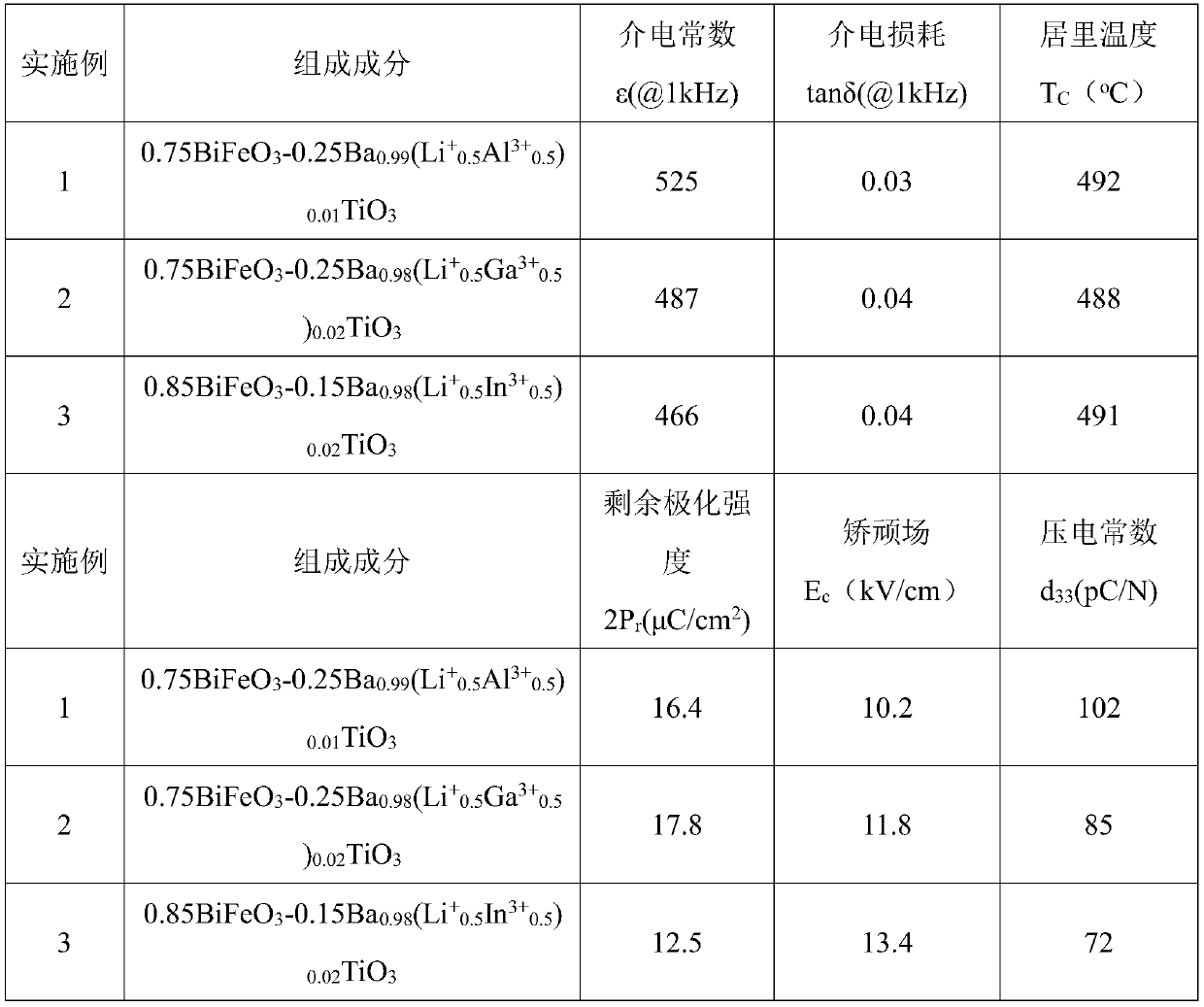

[0015] Specific Embodiment 1: In this embodiment, the general chemical formula of a compound-doped bismuth ferrite-barium titanate binary system lead-free ferroelectric ceramic material is (1-y)BiFeO 3 -yBa 1-x (Li + 0.5 A 3+ 0.5 ) x TiO 3 , where x and y are mole fractions, 0.005≤x≤0.06, 0.1≤y≤0.35, A 3+ Ion is Al 3+ , Ga 3+ 、In 3+ or Er 3+ ion.

specific Embodiment approach 2

[0016] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the compound doped bismuth ferrite-barium titanate binary system lead-free ferroelectric ceramic material has a general chemical formula of (1-y)BiFeO 3 -yBa 1-x (Li + 0.5 A 3+ 0.5 ) x TiO 3 , where x and y are mole fractions, 0.01≤x≤0.06, 0.15≤y≤0.3, A 3+ Ion is Al 3+ , Ga 3+ 、In 3+ or Er 3+ ion. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the compound doped bismuth ferrite-barium titanate binary system lead-free ferroelectric ceramic material has a general chemical formula of (1-y)BiFeO 3 -yBa 1-x (Li + 0.5 A 3+ 0.5 ) x TiO 3 , where x and y are mole fractions, 0.02≤x≤0.04, 0.2≤y≤0.25, A 3+ Ion is Al 3+ , Ga 3+ 、In 3+ or Er 3+ ion. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com