Vertical type rotary tank bioreactor for large-scale cell culturing

A bioreactor and large-scale culture technology, applied in the field of vertical rotating tank bioreactor, can solve the problem of rarely harvesting cells, and achieve the effect of avoiding pollution and saving production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

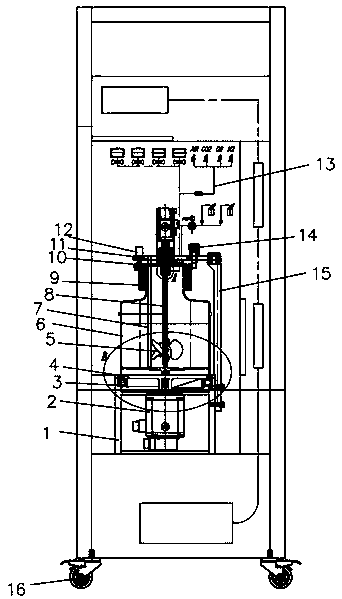

[0031] figure 1 It is a schematic diagram of the overall internal structure of the present invention. It can be seen in conjunction with the accompanying drawings that the rotary bioreactor for large-scale cultivation of the present invention includes a cultivation tank 6. In practical applications, the cultivation tank 6 is placed vertically. Culture cells in. During the cultivation process, the upper stirring motor drives the stirring paddle to rotate at a low speed to stir the culture medium so that the culture medium is evenly mixed. The bottom of the culture tank 6 is provided with a rotary drive device, which can drive the culture tank 6 to rotate at a high speed along its vertical central axis to generate centrifugal force, which can separate, concentrate and wash the cells. Driving the rotation of the culture tank 6 is not present in any culture tank 6, and the present invention combines the functions of the culture tank and the centrifuge, which is one of the most im...

Embodiment 2

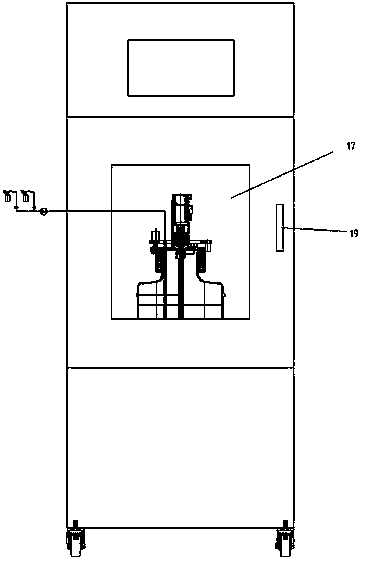

[0034] figure 2 It is a schematic example of the overall external structure of the present invention. As can be seen in conjunction with the accompanying drawings, the culture tank 6 is arranged in an incubator, and the side wall of the incubator is provided with an observation window 17. The box is also provided with a constant temperature system and a temperature display system. One side of the incubator is a door that can be rotated and opened, and a handle 19 is arranged on the door. The observation window 17 can be located on the door, or on other side walls of the incubator.

Embodiment 3

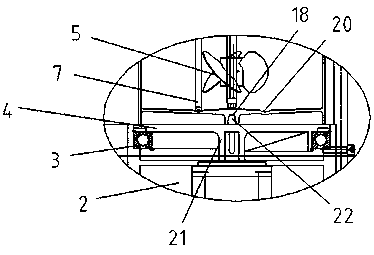

[0036] This example introduces in detail the specific means for achieving the culture tank 6 being driven to rotate by the bottom motor 2 and rotating at a high speed, and sealing the tank mouth. image 3 yes figure 1 In the partial enlarged view of B, it can be seen in conjunction with the accompanying drawings that the bottom of the culture tank 6 is provided with a cross groove 18, the rotation drive device includes a rotary tray 4 and a bottom motor 2, and the upper surface of the rotary tray 4 is provided with The cross protruding strips 22 intersect, the intersection point of the cross protruding strips 22 is located at the center of the rotating tray 4 , the rotating tray 4 is arranged in contact with the bottom of the thickened base, and the cross protruding strips 22 are inserted into the cross grooves 18 exactly. The intersection point of the cross groove 18 is located at the center of the thickened base. Inserting the cross protruding strip 22 into the cross groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com