Water-soluble corrosion inhibitor

A water-soluble and corrosion inhibitor technology, applied in the field of water-soluble corrosion inhibitors, can solve the problems of poor dispersibility of raw material oil and failure to develop, and achieve the effect of good dispersibility and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

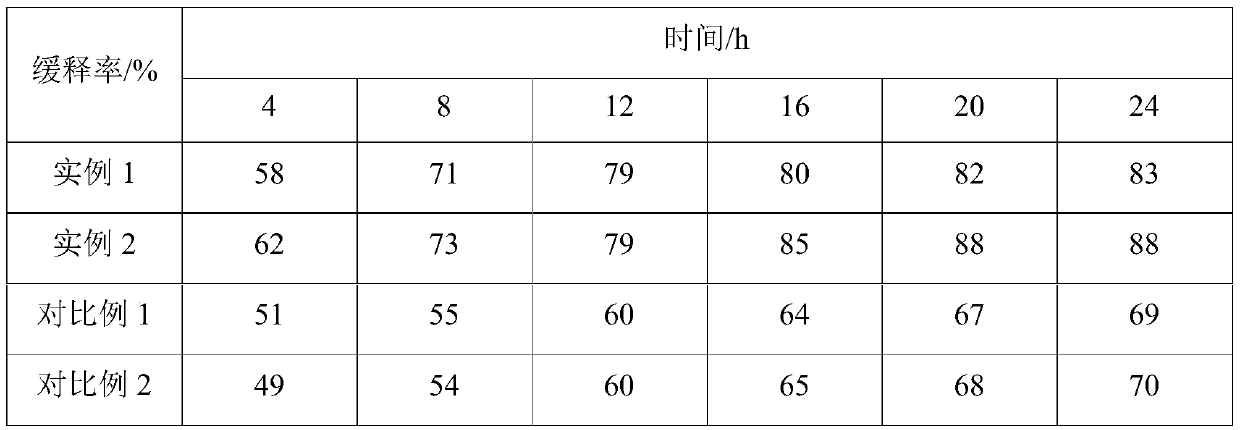

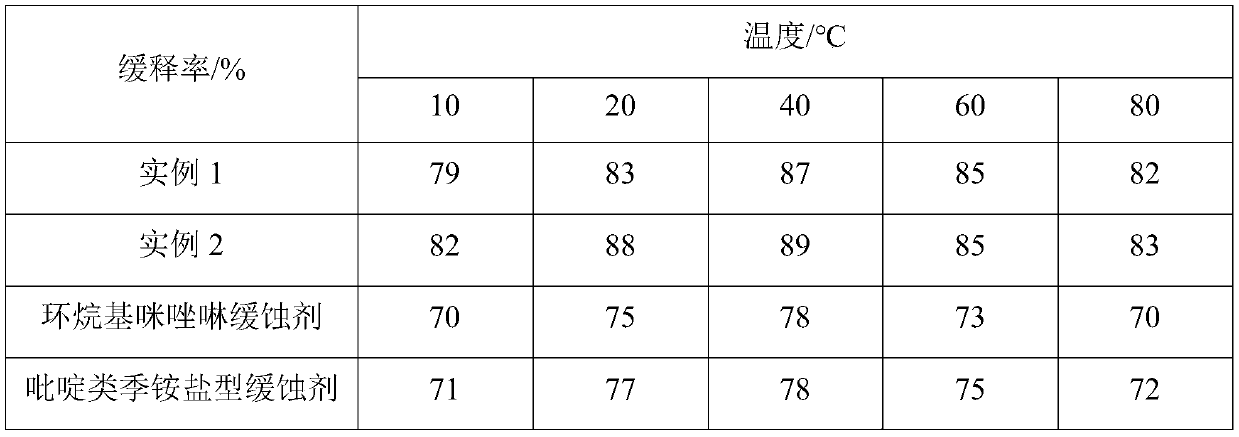

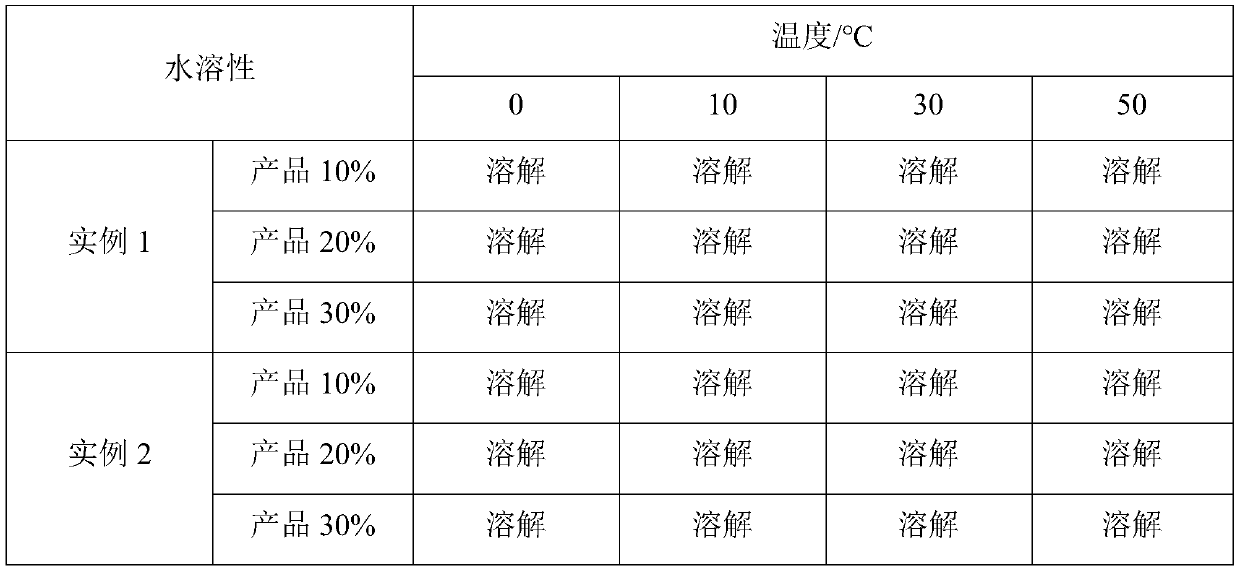

Examples

example 1

[0020] Water-soluble corrosion inhibitor, prepared by the following method:

[0021] Step 1. Put palmitic acid, activated alumina, toluene, and zeolite into the reactor, stir, heat up to 80°C, put in N-phenylethylenediamine, heat up to 180°C, and heat up to temperature at a heating rate of 5°C / min 220℃, heat preservation for 2h, heat up to 260℃ at a heating rate of 2℃ / min, keep for 3h, carry out amidation reaction, distill toluene under reduced pressure, remove the water produced by the reaction, and cool to 120℃ to obtain oil-soluble An intermediate, wherein the molar ratio of palmitic acid to N-phenylethylenediamine is 1:1.2;

[0022] Step 2: Mix the oil-soluble intermediate with methyl bromide and reflux at 50°C for 4 hours to perform quaternization to obtain a water-soluble intermediate, wherein the molar ratio of the oil-soluble intermediate to methyl bromide is 1:1.2;

[0023] Step 3: Mix the water-soluble intermediate with 1-butyl-3-methylimidazole tetrafluoroborate in a mass...

example 2

[0026] Water-soluble corrosion inhibitor, prepared by the following method:

[0027] Step 1. Put palmitic acid, activated alumina, sulfonic acid, toluene, and zeolite into the reaction kettle, stir, heat up to 80°C, put in N-phenylethylenediamine, heat up to 180°C, and heat at 5°C / min The rate is increased to 220°C, the temperature is kept for 2h, and the heating rate is 2°C / min to 260°C, and the temperature is kept for 3h. The amidation reaction is carried out. The toluene is distilled off under reduced pressure, and the water produced by the reaction is removed and cooled to 120°C Obtain an oil-soluble intermediate, wherein the molar ratio of palmitic acid to N-phenylethylenediamine is 1:1.2;

[0028] Step 2: Mix the oil-soluble intermediate with methyl bromide and reflux at 50°C for 4 hours to perform quaternization to obtain a water-soluble intermediate, wherein the molar ratio of the oil-soluble intermediate to methyl bromide is 1:1.2;

[0029] Step 3. Using bromo-n-butane and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com