Device for washing hands and feet on bed

A hand-washing, square-shaped technology, applied in medical transportation and other directions, can solve the problems of high labor intensity, easy water splashing, and discomfort for patients to wash their hands, and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

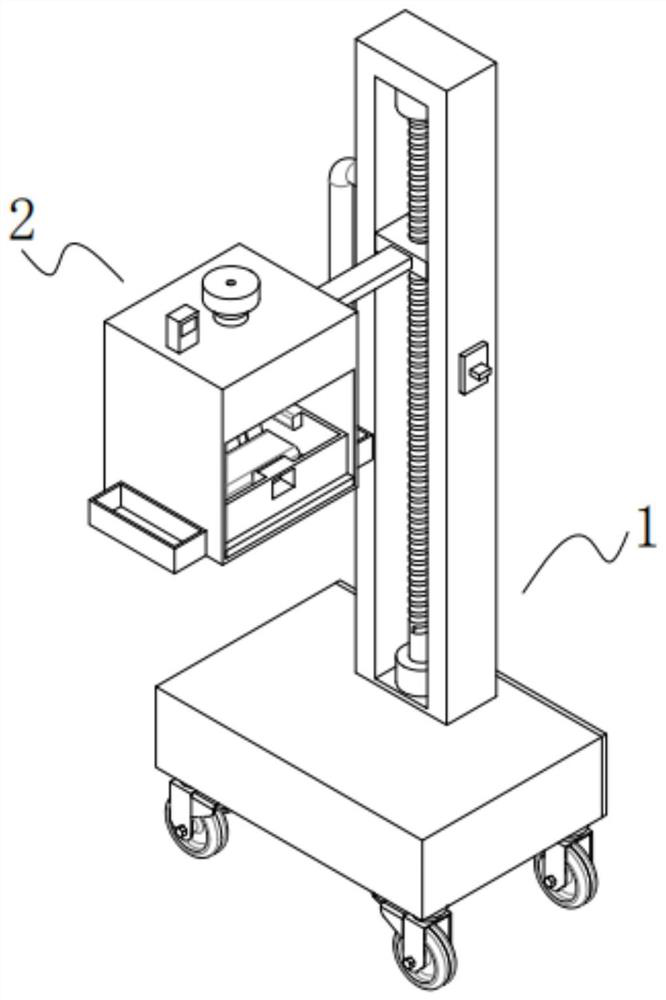

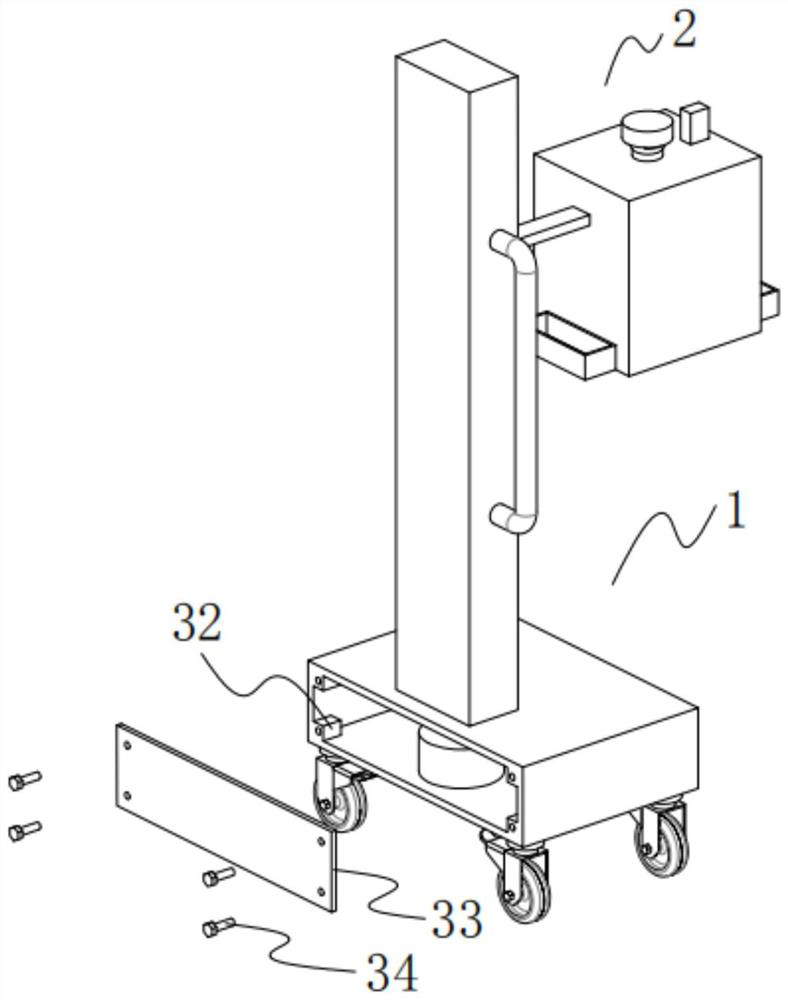

[0059] A device for washing hands and feet on the bed, such as figure 1 As shown, it includes a lifting unit 1 and a hand-washing and foot-washing unit 2, and the hand-washing and foot-washing unit 2 is fixedly connected to the lifting unit 1;

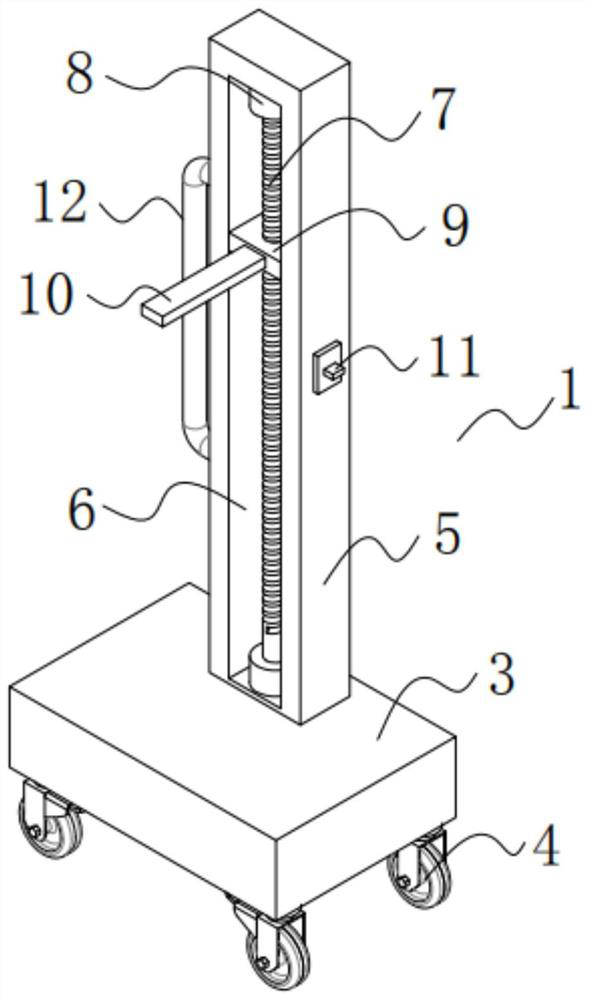

[0060] like image 3 and 4 As shown, the lifting unit 1 includes a hollow base 3, a square column 5, a screw rod 7, a square slider 9, a connecting rod 10 and a motor 13, and the square column 5 is fixed and vertically installed on the hollow base 3 The upper part of the square column 5 is provided with a square chute 6 on one side of the square column 5. The screw rod 7 is fixed and vertically installed in the inside of the square chute 6 through two rolling bearings 8. The square chute 6 The block 9 is threaded on the outside of the screw rod 7, and the two end surfaces of the square slider 9 are fitted to the two inner surfaces of the square chute 6, and the connecting rod 10 is fixed and installed horizontally on the One side of...

Embodiment 2

[0085] The difference from Example 1 is that the inner surface of the square chute 6 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0086] Take the following raw materials and weigh them by weight: 18 parts of epoxy resin, 8 parts of calcium carbonate powder, 10 parts of talcum powder, 12 parts of silicon carbide particles, 8 parts of aluminum oxide particles, 15 parts of glass powder, 12 parts of alcohol ester twelve 2 parts of BDMA, 1 part of higher alcohol fatty acid ester complex and 30 parts of ethanol;

[0087] S1, adding the weighed alcohol ester twelve, BDMA, higher carbon alcohol fatty acid ester complex and ethanol into the mixer and stirring for 23min, the stirring speed is 500r / min, and a mixed solution is obtained;

[0088] S2, adding epoxy resin, calcium carbonate powder, talcum powder, silicon carbide particles, aluminum oxide particles and glass powder into a pulverizer for pulverization until the parti...

Embodiment 3

[0094] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0095] Take the following raw materials and weigh them by weight: 22 parts of epoxy resin, 10 parts of calcium carbonate powder, 11 parts of talcum powder, 14 parts of silicon carbide particles, 9 parts of aluminum oxide particles, 18 parts of glass powder, 3 parts of alcohol ester twelve 3 parts of BDMA, 2 parts of higher alcohol fatty acid ester complex and 40 parts of ethanol;

[0096] S1, adding the weighed alcohol ester twelve, BDMA, higher carbon alcohol fatty acid ester complex and ethanol into the mixer and stirring for 26min, the stirring speed is 600r / min, and a mixed solution is obtained;

[0097] S2, adding epoxy resin, calcium carbonate powder, talcum powder, silicon carbide particles, aluminum oxide particles and glass powder into a pulverizer for pulverization until the particle diameter of the material is not greater than 100nm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com