Preparation method of autosoluble hyaluronic acid microneedles

A technology of hyaluronic acid and autolysis, which is applied in the field of preparation of autolyzed hyaluronic acid microneedles, can solve the problems of skin irritation, drug activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

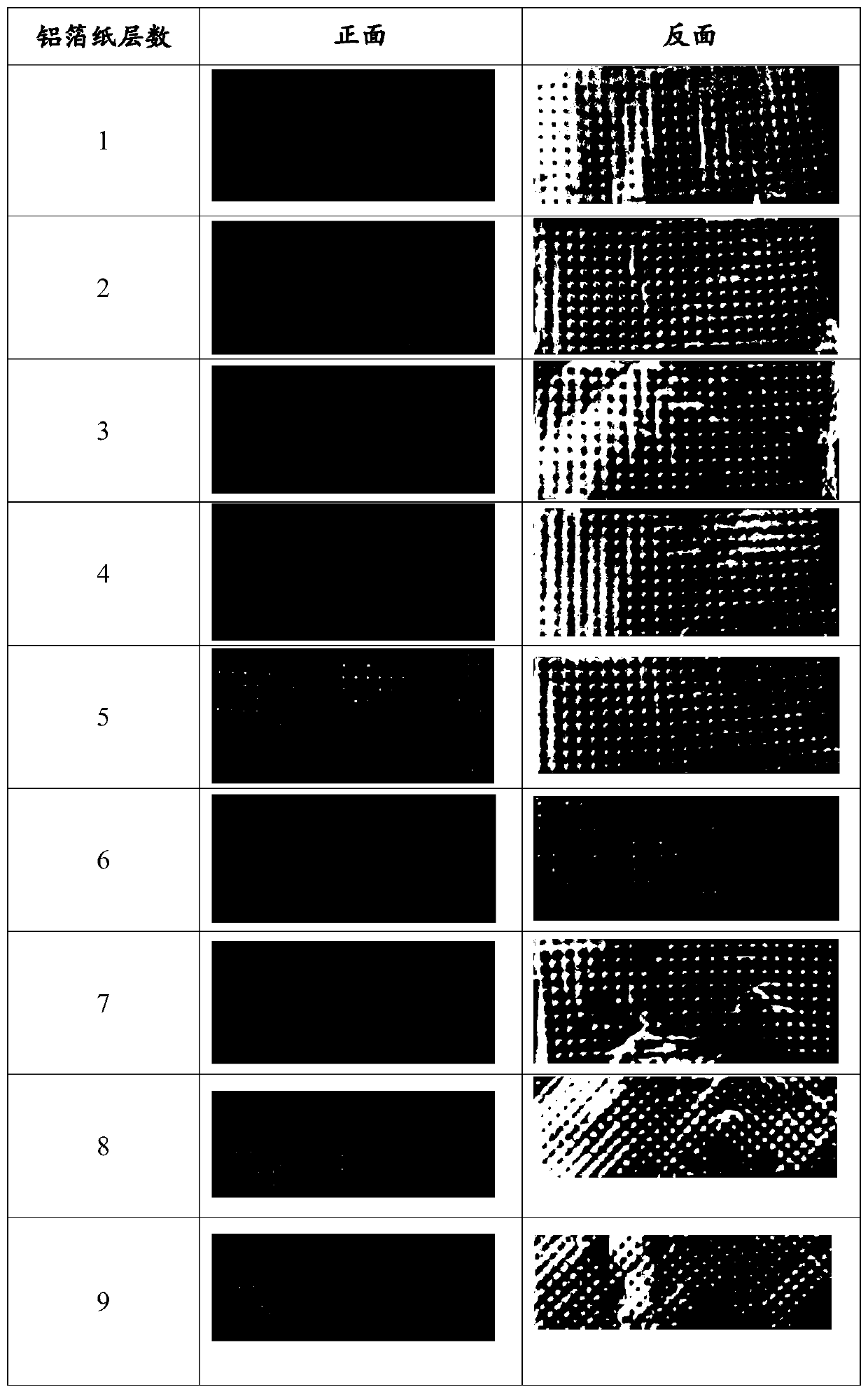

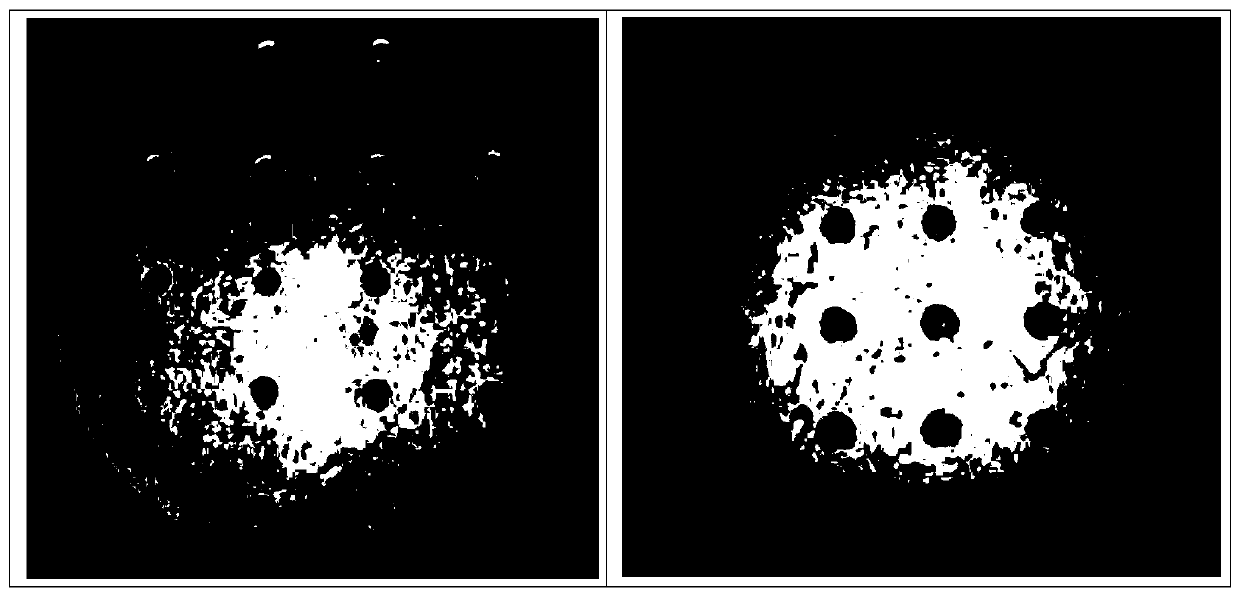

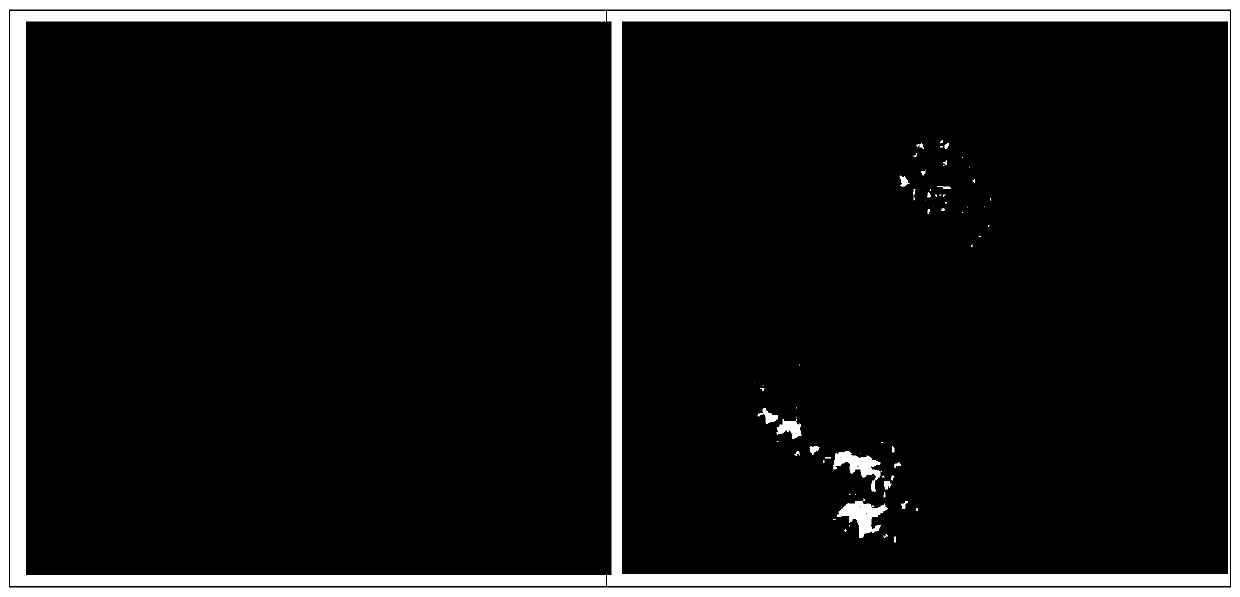

Image

Examples

Embodiment 1

[0038] A preparation method of self-dissolving hyaluronic acid microneedles, comprising the steps of:

[0039] (1) Take an appropriate amount of pure hyaluronic acid with a molecular weight of 5KDa, add purified water at a mass volume ratio (g / mL) of 1:50, swell in a water bath at 30°C for 30 minutes, and stand at room temperature to remove bubbles in the solution to obtain a uniform hyaluronic acid. Hyaluronic acid clarification solution, spare;

[0040] (2) Clean the PDMS (Polydimethylsiloxane) microneedle mold, air-dry, and set aside;

[0041] (3) Take the hyaluronic acid clarified solution in step (1), cast it onto the PDMS microneedle mold naturally, and shake it back and forth to ensure that it is evenly spread; the dosage of the above hyaluronic acid clarified solution is 0.12ml / cm 2 ;

[0042] (4) Put the PDMS microneedle mold coated with the clarified hyaluronic acid solution in a vacuum drying oven at 30°C, evacuate to 0.06MPa, hold the pressure for 2.5min, slowly ...

Embodiment 2

[0044] A preparation method of self-dissolving hyaluronic acid microneedles, comprising the steps of:

[0045] (1) Take an appropriate amount of pure hyaluronic acid with a molecular weight of 10KDa, add purified water at a mass volume ratio (g / mL) of 3:100, swell in a water bath at 35°C for 35 minutes, and stand at room temperature to remove bubbles in the solution to obtain a uniform hyaluronic acid. Hyaluronic acid clarification solution, spare;

[0046] (2) Clean the PDMS (Polydimethylsiloxane) microneedle mold, air-dry, and set aside;

[0047] (3) Take the hyaluronic acid clarified solution in step (1), cast it onto the PDMS microneedle mold naturally, and shake it back and forth to ensure that it is evenly spread; the dosage of the above hyaluronic acid clarified solution is 0.15ml / cm 2 ;

[0048] (4) Put the PDMS microneedle mold coated with the clarified hyaluronic acid solution in a vacuum drying oven at 30°C, evacuate to 0.06 MPa, hold the pressure for 3 minutes, a...

Embodiment 3

[0050] A preparation method of self-dissolving hyaluronic acid microneedles, comprising the steps of:

[0051] (1) Take an appropriate amount of pure hyaluronic acid with a molecular weight of 1KDa, add purified water at a mass volume ratio (g / mL) of 1:100, swell in a water bath at 25°C for 25 minutes, and stand at room temperature to remove bubbles in the solution to obtain a uniform hyaluronic acid. Hyaluronic acid clarification solution, spare;

[0052](2) Clean the PDMS (Polydimethylsiloxane) microneedle mold, air-dry, and set aside;

[0053] (3) Take the clear solution of hyaluronic acid in step (1), cast it onto the PDMS microneedle mold naturally, and shake it back and forth to ensure that it is evenly spread; the dosage of the above clear solution of hyaluronic acid is 0.09ml / cm 2 ;

[0054] (4) Put the PDMS microneedle mold coated with the clarified hyaluronic acid solution in a vacuum drying oven at 30°C, evacuate to 0.06MPa, hold the pressure for 2min, and slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com