A CNC machine tool for a revolver ejection tool changer for machining

A technology of mechanical processing and CNC machine tools, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., and can solve the problems of high space occupation ratio of tool holders, passivation of tools, and large space expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

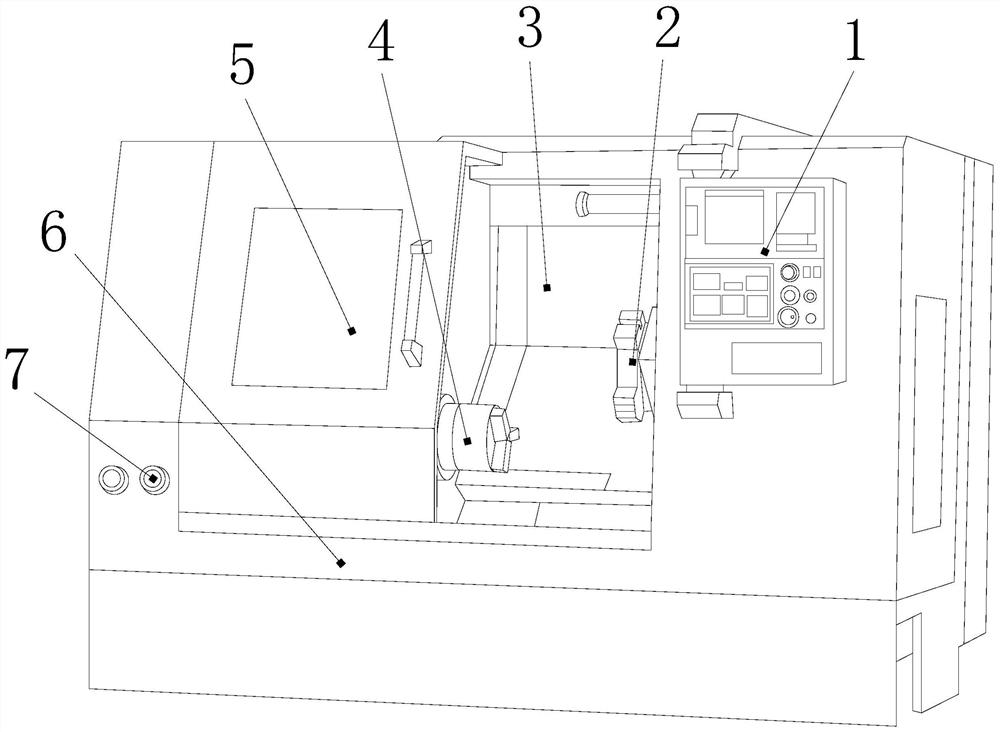

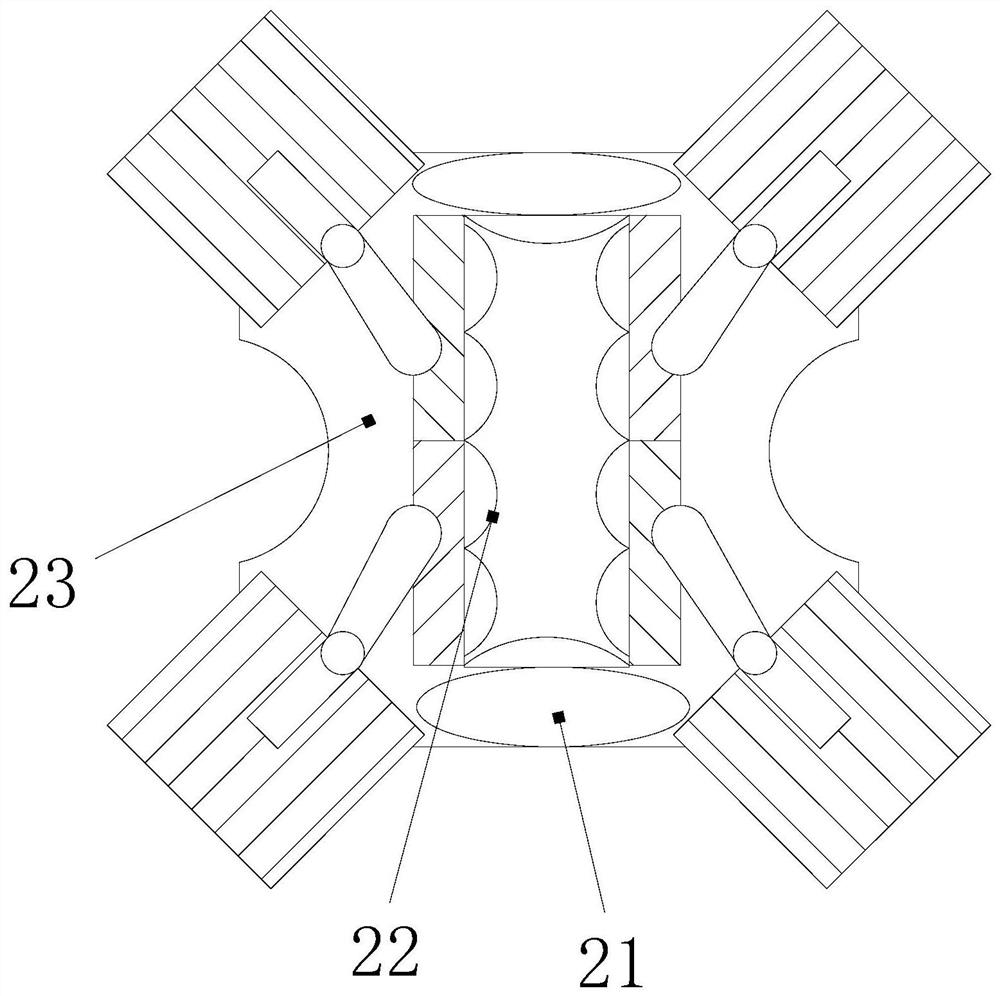

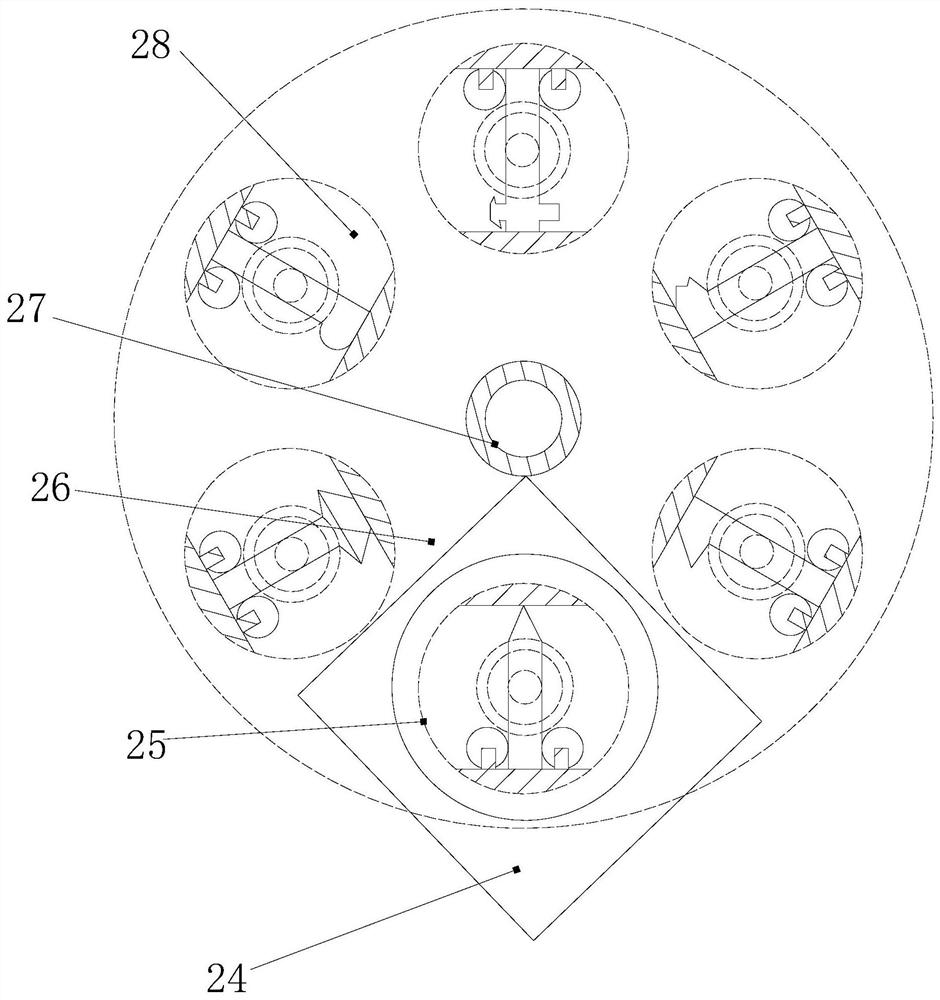

[0031]SeeFigure 1 - Figure 8The present invention provides a CNC machine tool for mechanical machining of the revolving replacement reservoir, including: industrial control display screen 1, roulette start 2, processing warehouse 3, three jaw chuck 4, warehouse mask Skateboard 5, machine case holder 6, air pressure table 7, the wheel scaffolding frame 2 mechanically couples through the roller roller and the bearing of the machining bin 3, the processing bin 3 is nested in the machine bed, the air pressure Table 7 is provided with two and both inserted into the lower left corner of the machine case holder 6, the trunculating chuck 4 mounted on the lower left corner of the processing bin 3, the bottom of the warehouse slide 5 through the track and machine cover The seat 6 active connection, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com