Method for improving grade of crude product of cobaltous hydroxide

A cobalt hydroxide and crude technology, applied in the field of hydrometallurgy, can solve the problems of poor quality of crude cobalt hydroxide, increased extraction cost, high content of manganese and magnesium, achieve good industrial application prospects, reduce the cost of extraction agent and The effect of transportation cost and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

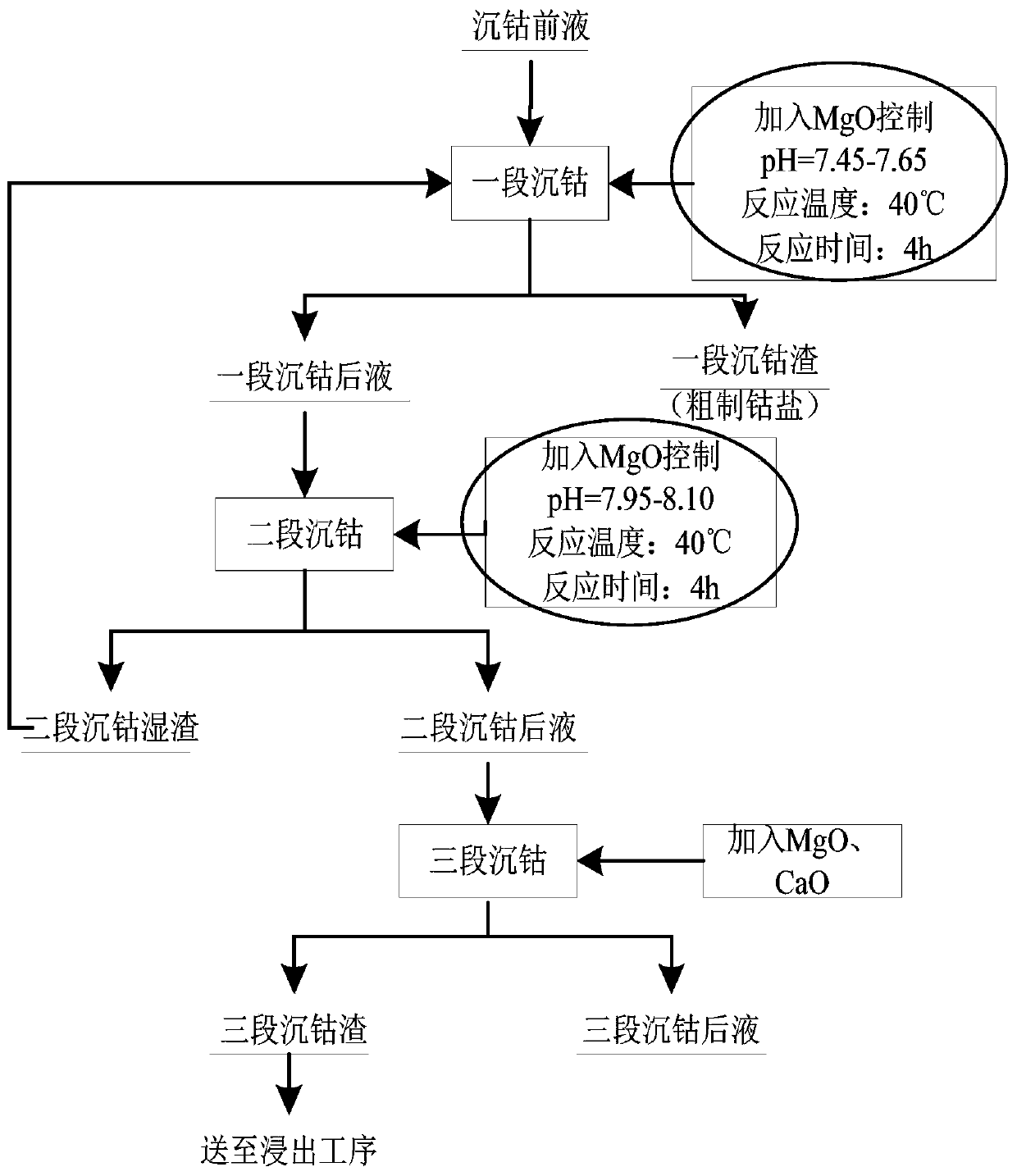

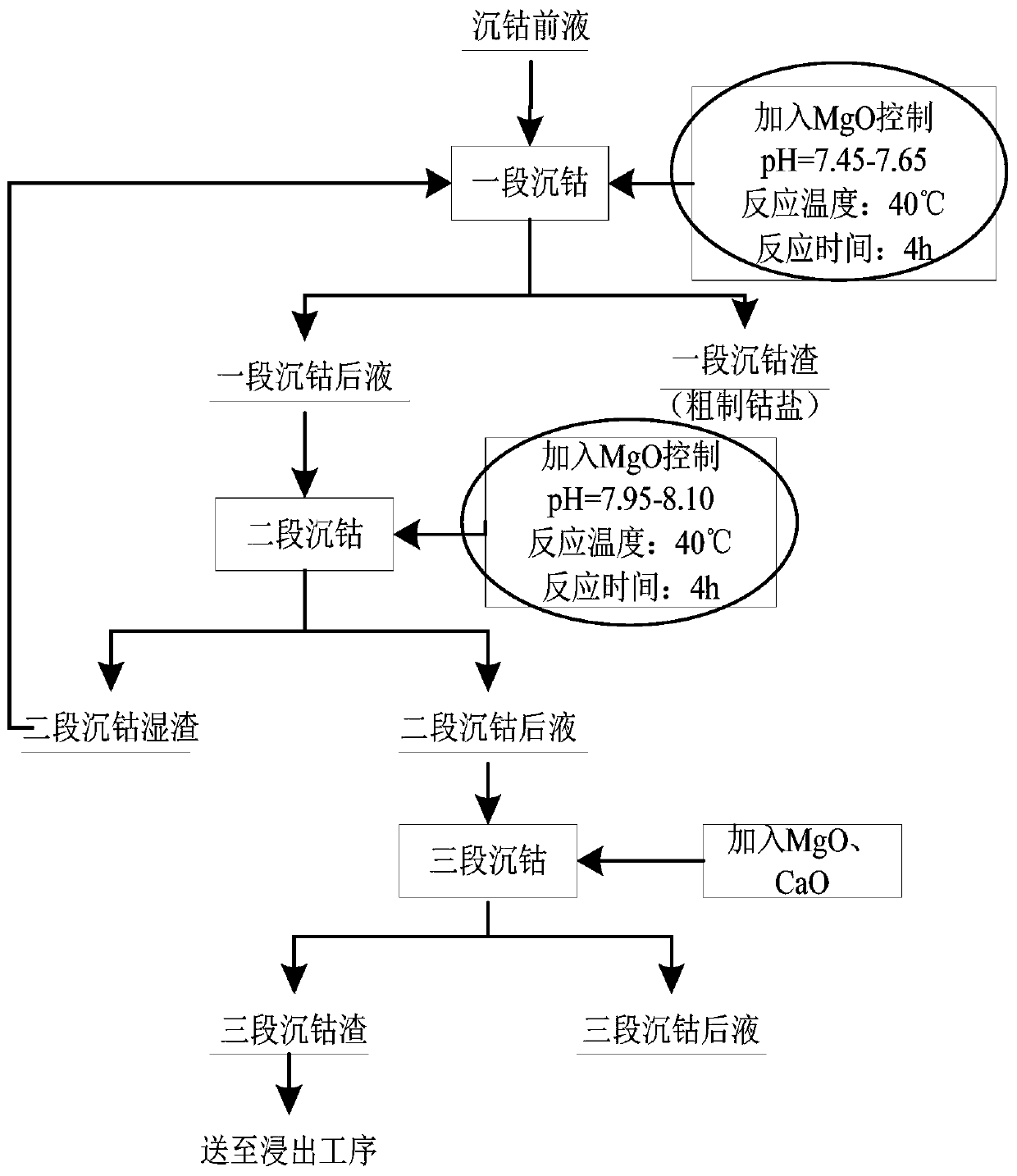

Method used

Image

Examples

Embodiment

[0041]A part of the embodiments of the present invention, but not all the embodiments, based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without innovative work, all belong to the protection scope of the present invention.

[0042] In the example, the pre-precipitation solution of cobalt was prepared for a company in the Democratic Republic of the Congo in Africa, and its main components are shown in Table 1:

[0043] Table 1 Contents of main elements in the solution before cobalt precipitation (g / L)

[0044] element co Cu Ni Fe Al mn Mg Ca pH content 18.36 0.0082 0.132 0.0003 0.0001 2.4 7.57 0.18 4.79

[0045] In the embodiment, MC40 magnesium oxide is provided by a company in the Democratic Republic of the Congo in Africa, and active magnesium oxide is purchased from the market in Kyowa Japan, and the main indicators are shown in Table 2:

[0046] Table main components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com