Aluminum electrolysis continuous prebaked anode composite heat preservation method and structure

A pre-baked anode and composite heat preservation technology is applied in the field of aluminum electrolysis continuous pre-baked anode composite heat preservation method and structure, which can solve the problems of poor heat preservation effect, heat loss, inconvenient removal, etc., achieves great energy saving effect, reduces oxidation loss, The effect of reducing heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

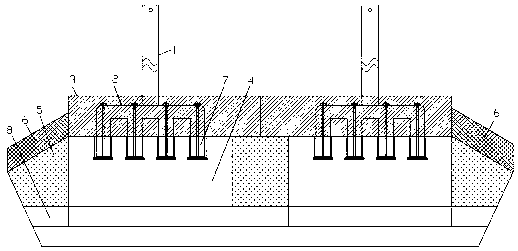

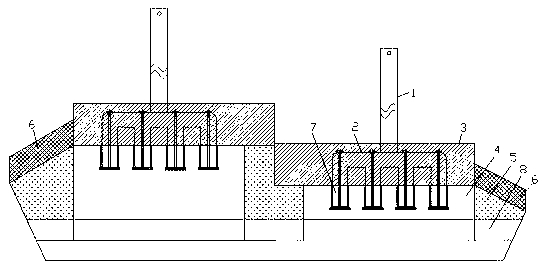

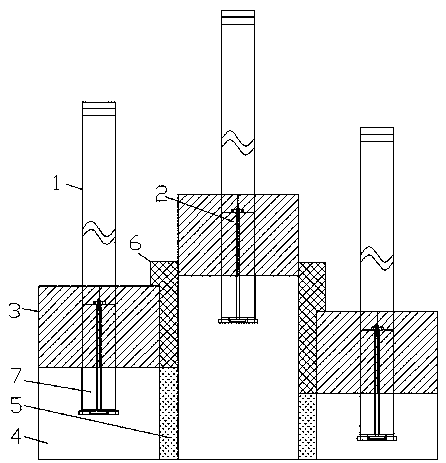

[0036] Example. A kind of aluminum electrolysis continuous prebaked anode composite insulation method, such as Figure 1-6 As shown, under the premise that the aluminum oxide insulation covering material 5 around the existing prebaked anode carbon block 4 and around the inside of the electrolytic cell 8 is retained, and the aluminum oxide insulation covering material 5 on the upper surface of the anode carbon block 4 is removed, the The upper surface of the anode carbon block 4, the aluminum oxide heat preservation covering material 5 around the anode carbon block 4, and the aluminum oxide heat preservation covering material 5 around the inside of the electrolytic cell 8 are covered with a foam heat preservation cover plate 3, supplemented by a foam heat preservation sealing auxiliary small Bar 6 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com