Rubrene: MoO3 mixed thin film-based infrared detector

A thin film and glass substrate technology is applied in the field of infrared detector preparation to achieve the effect of enriching preparation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

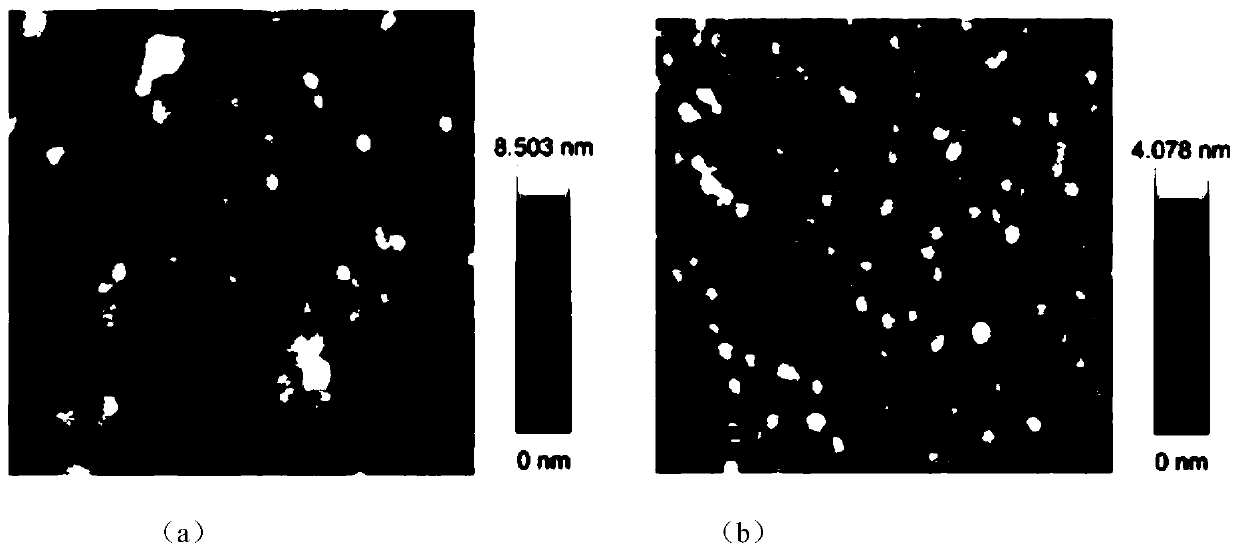

[0016] (a)

[0017] (1) Using a glass substrate as a substrate, the substrate was ultrasonically cleaned in toluene, acetone, ethanol solution and deionized water for 15 minutes, and then cleaned with N in a glove box. 2 Dry and set aside.

[0018] (2) Using a high-vacuum organic-metal composite evaporation system, at 5×10 -4 Heating Rubrene and MoO under high vacuum environment in Pa 3 powder, prepared Rubrene:MoO 3 (mass ratio of 1:1) mixed film, and vacuum in-situ annealing; for comparison, Rubrene and MoO were prepared under the same environment 3 The intrinsic film, which has the same thickness as the hybrid film, is 200 nm.

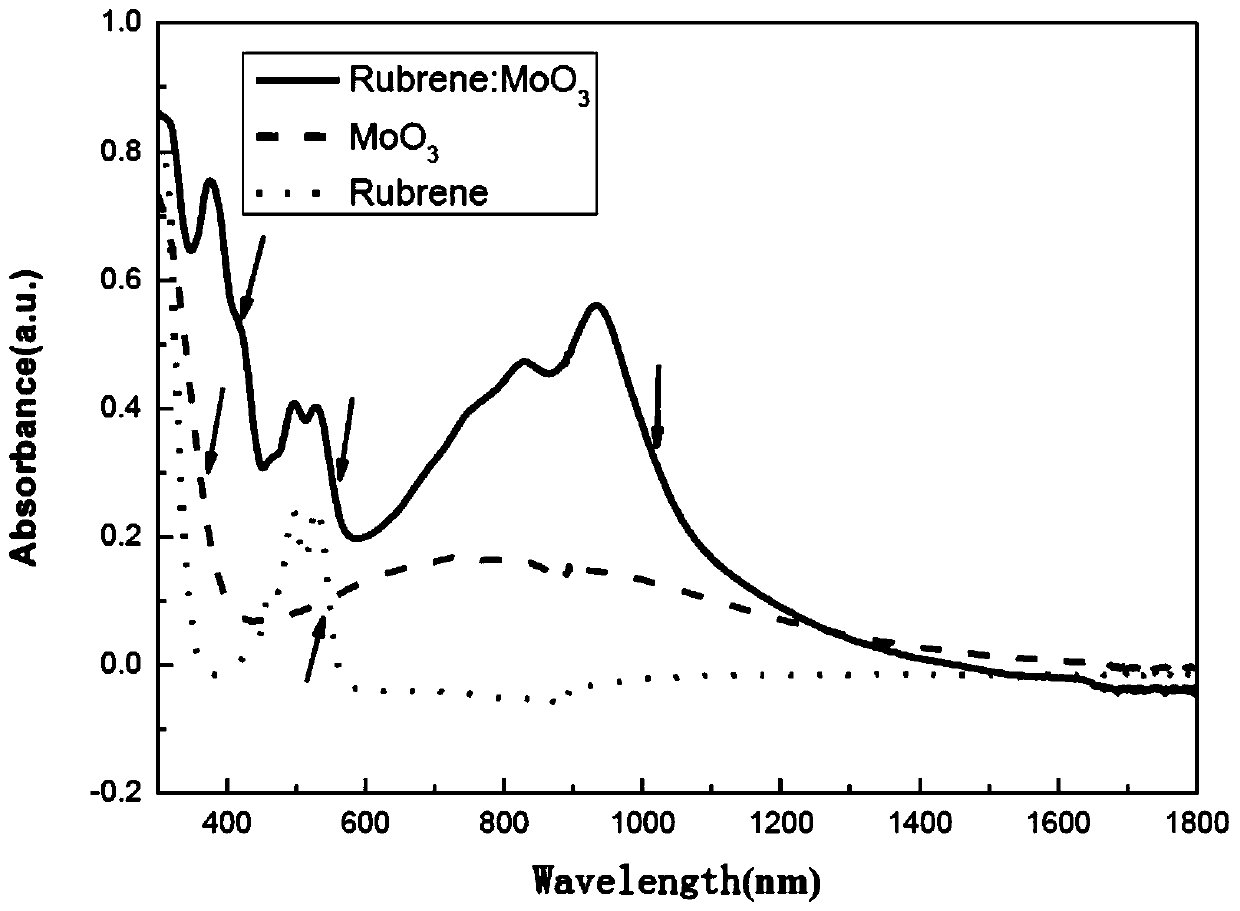

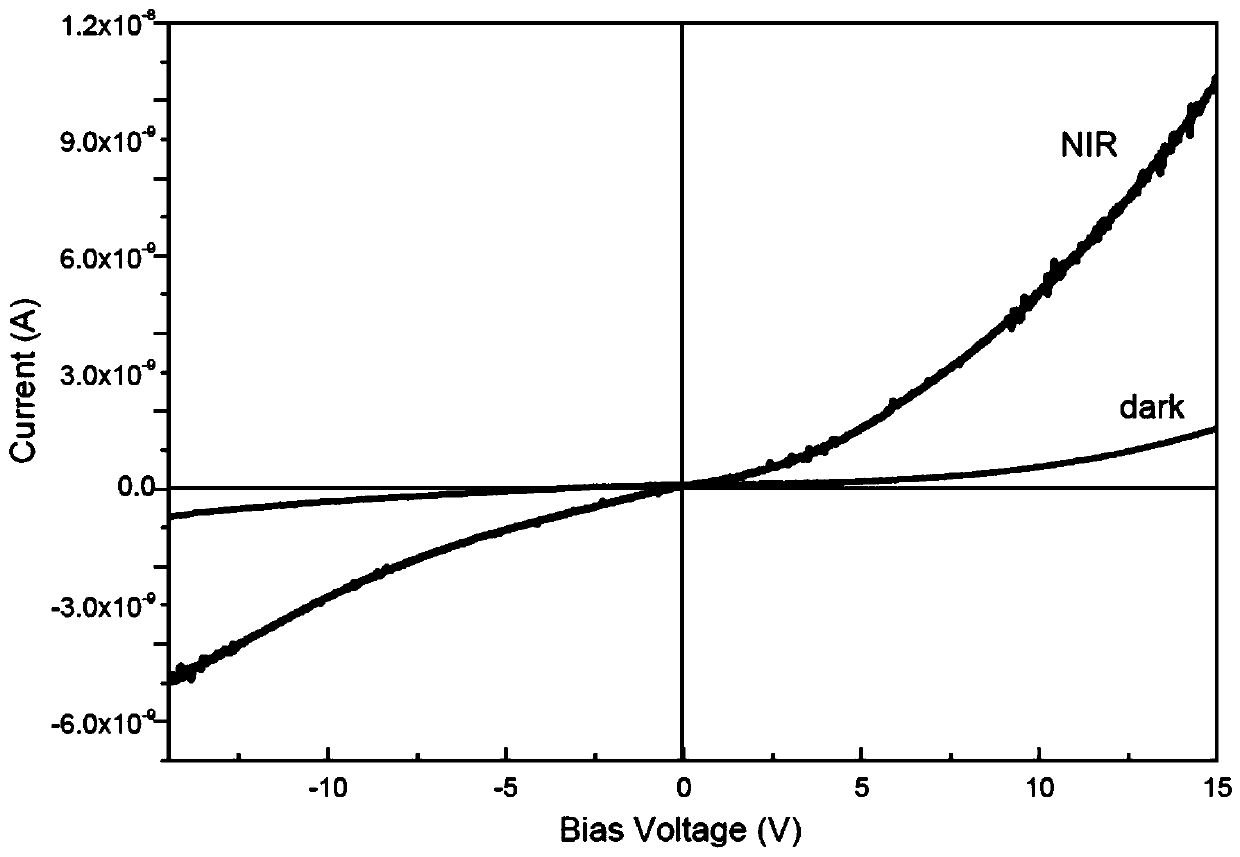

[0019] (3) Tested Rubrene:MoO 3 Optical properties of hybrid films.

[0020] (b)

[0021] (1) Using a glass substrate as a substrate, the substrate was ultrasonically cleaned in toluene, acetone, ethanol solution and deionized water for 15 minutes, and then cleaned with N in a glove box. 2 Dry and set aside.

[0022] (2) Using a high-vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com