Preparation method and application of lanthanum-loaded modified bentonite dephosphorization material

A bentonite and modified technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low biological phosphorus removal efficiency, potential safety hazards of raw materials, and low phosphorus removal efficiency, etc. Good phosphorus removal effect, low cost and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

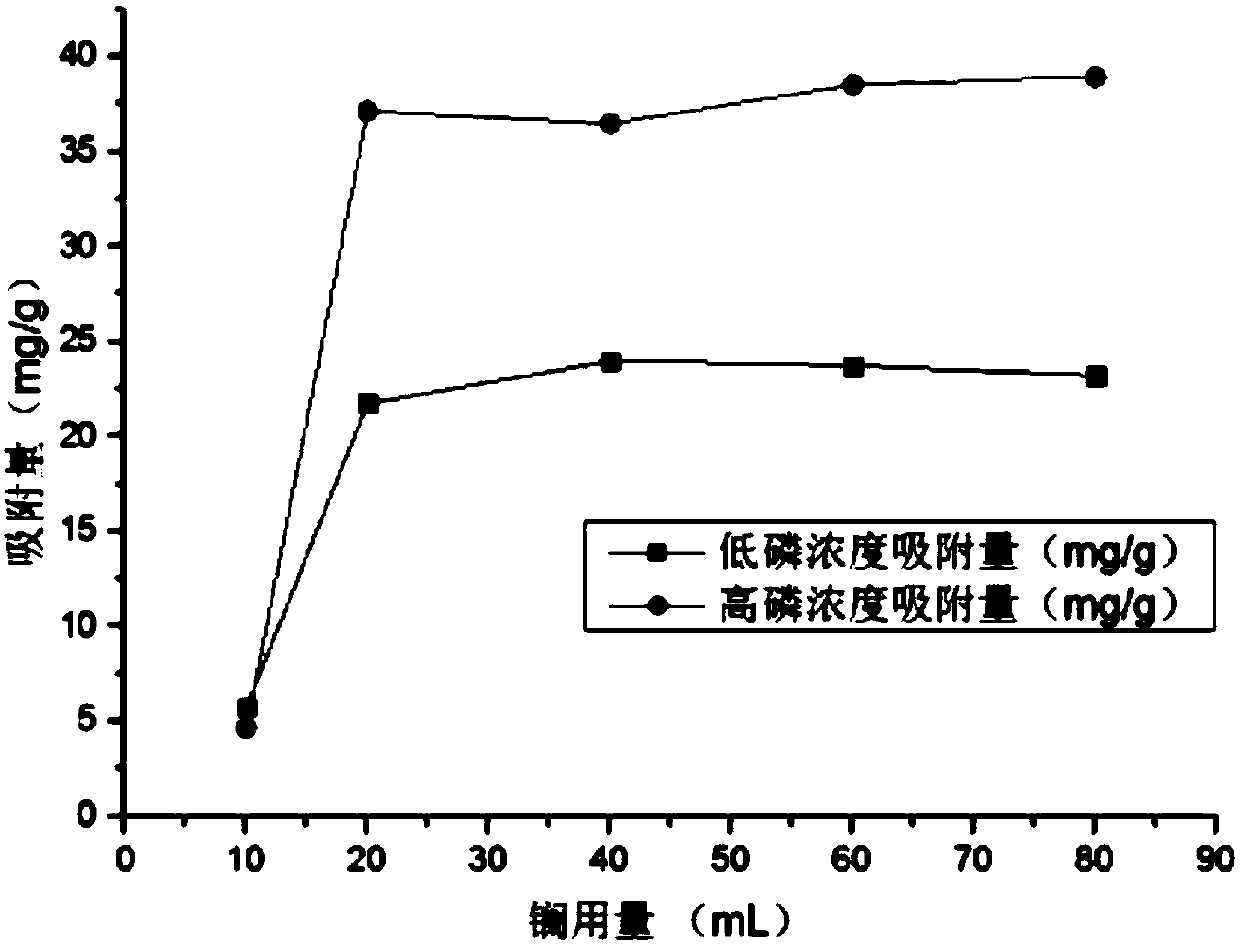

[0025] Single factor experiment of solid-liquid ratio of lanthanum modified bentonite

[0026] Material preparation: use 10, 20, 40, 60, 80mL 0.1mol / L LaCl respectively 3 Adjust the pH of the solution to 10 with 1mol / L NaOH in an ultrasonic cleaner and disperse it evenly by ultrasonication for 2 minutes, add 1.5g of bentonite and ultrasonic for 40 minutes, filter, wash, and dry at 105°C.

[0027] Adsorption test: Add 0.04g (1g / L) material to 40mL potassium dihydrogen phosphate solution with a concentration of 50mg / L, adsorb in an air shaker at 150rpm and 25°C for 1h, and measure the residual phosphorus concentration in the supernatant.

[0028] The mass ratio of table 1 bentonite and lanthanum chloride

[0029]

[0030] The adsorption capacity at high phosphorus concentration and low phosphorus concentration is as shown in the attached figure 2 .

Embodiment 2

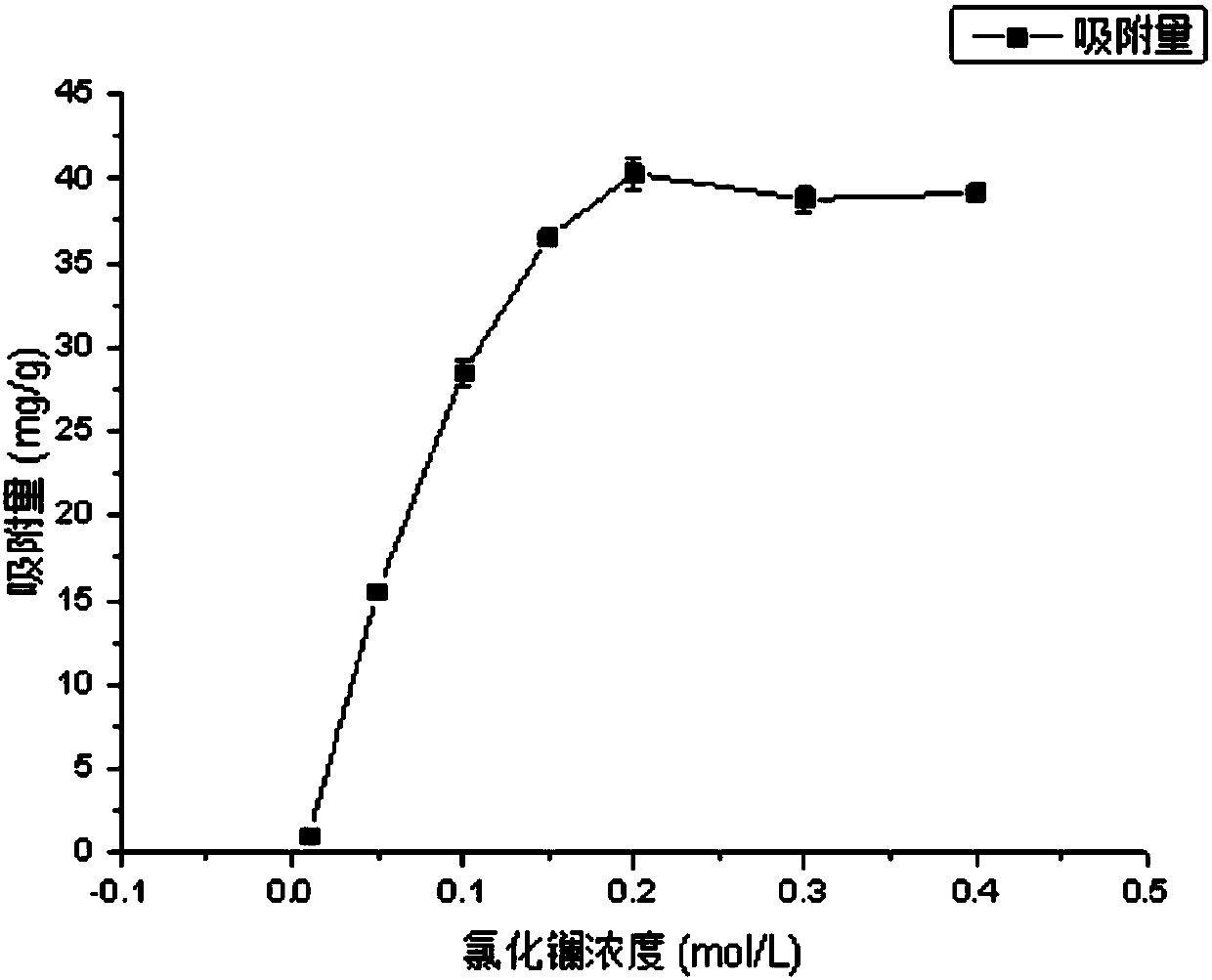

[0032] Lanthanum concentration single factor experiment

[0033] Material preparation: 40mL 0.01, 0.05, 0.1, 0.15, 0.2mol / L LaCl 3 Adjust the pH of the solution to 10 with 1mol / L NaOH in an ultrasonic cleaner and disperse it evenly by ultrasonication for 2 minutes. Add 3g of bentonite and ultrasonic for 40 minutes, filter, wash, and dry at 105°C.

[0034] Adsorption test: Add 0.04g (1g / L) material to 40mL potassium dihydrogen phosphate solution with a concentration of 50mg / L, adsorb in an air shaker at 150rpm and 25°C for 1h, and measure the residual phosphorus concentration in the supernatant. The test data is shown in Table 2, and the line graph drawn is as follows image 3 .

[0035] Phosphorus removal effect of different lanthanum chloride concentrations in table 2

[0036]

Embodiment 3

[0038] Ultrasonic time single factor experiment

[0039] Material preparation: 40mL 0.1mol / L LaCl 3 Adjust the pH of the solution to 10 with 1mol / L NaOH in an ultrasonic cleaner and disperse it evenly by ultrasonication for 2min. Add 3g of bentonite and ultrasonicate for 3, 5, 10, 20, and 40min respectively, filter, wash, and dry at 105°C.

[0040] Adsorption test: Add 0.04g (1g / L) material to 40mL potassium dihydrogen phosphate solution with a concentration of 50mg / L, adsorb in an air shaker at 150rpm and 25°C for 1h, and measure the residual phosphorus concentration in the supernatant. The experimental data are shown in Table 3, and the line graph drawn is as follows Figure 4 .

[0041] Table 3 Phosphorus removal effect of different ultrasonic time

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com