Ultra-precision processing tool and processing method for optically complex surface of single crystal silicon

An ultra-precision machining, complex surface technology, applied in optical surface grinders, manufacturing tools, metal processing equipment, etc., can solve the problems of low precision and low processing efficiency, achieve high manufacturing precision, good surface quality, wear resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

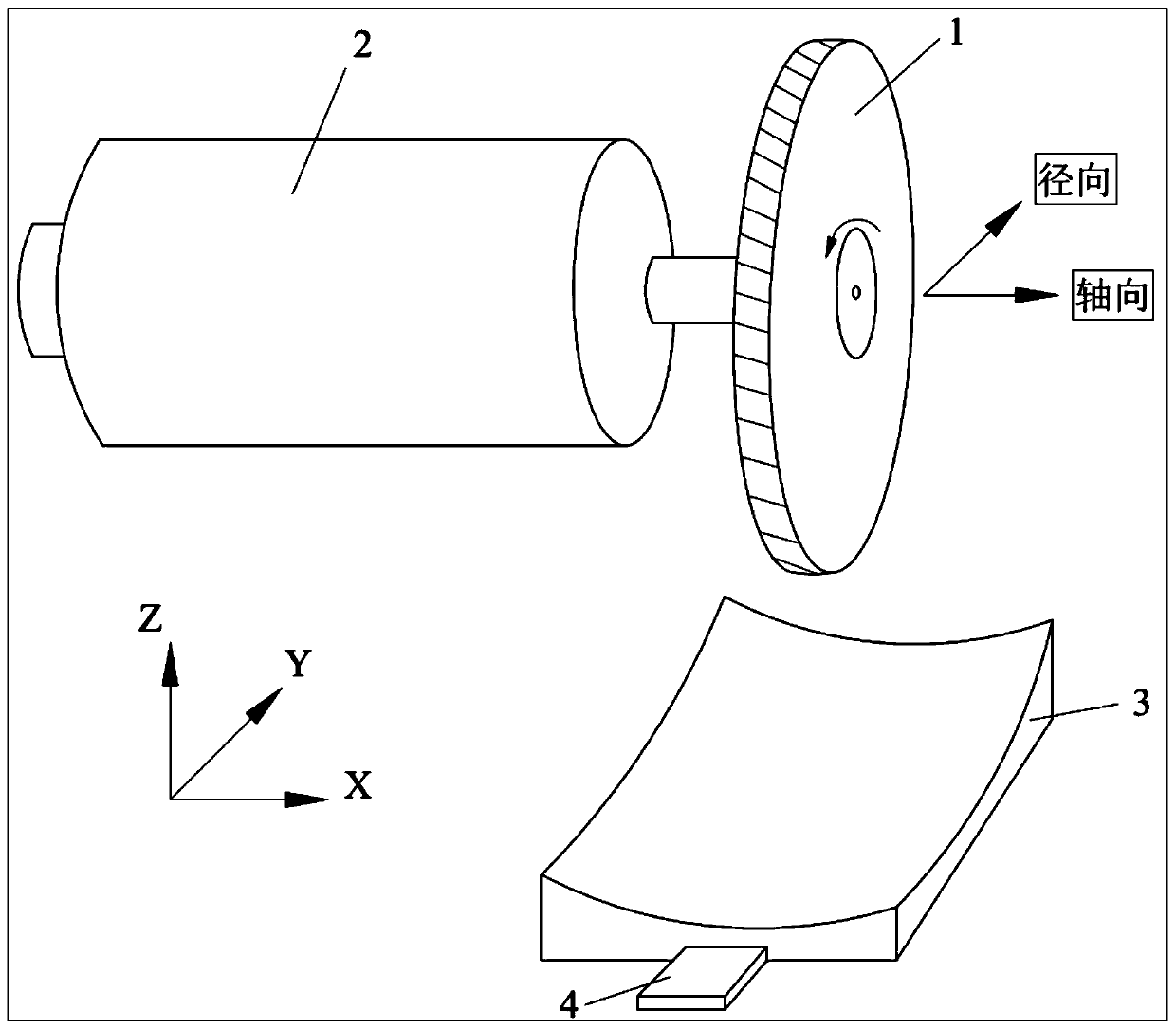

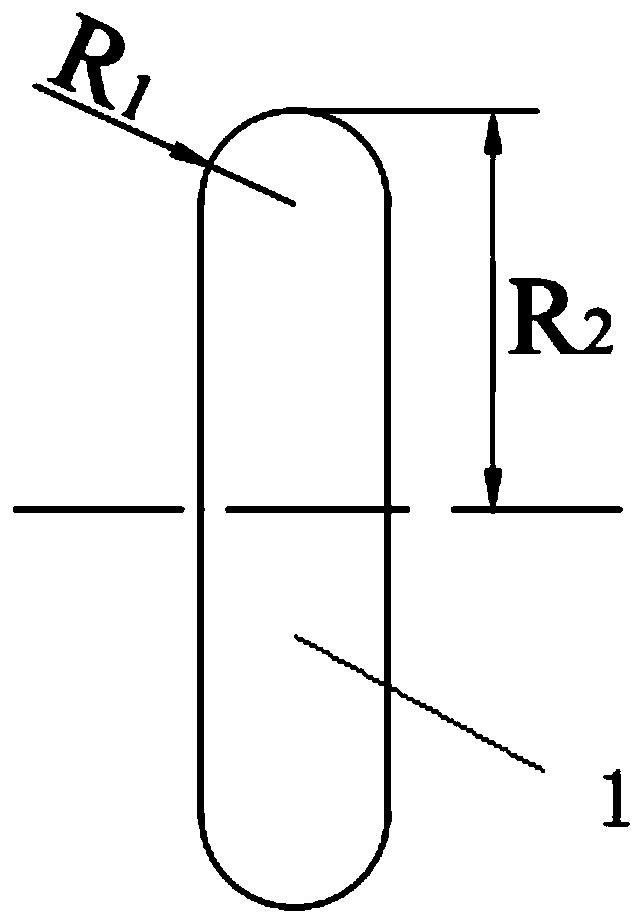

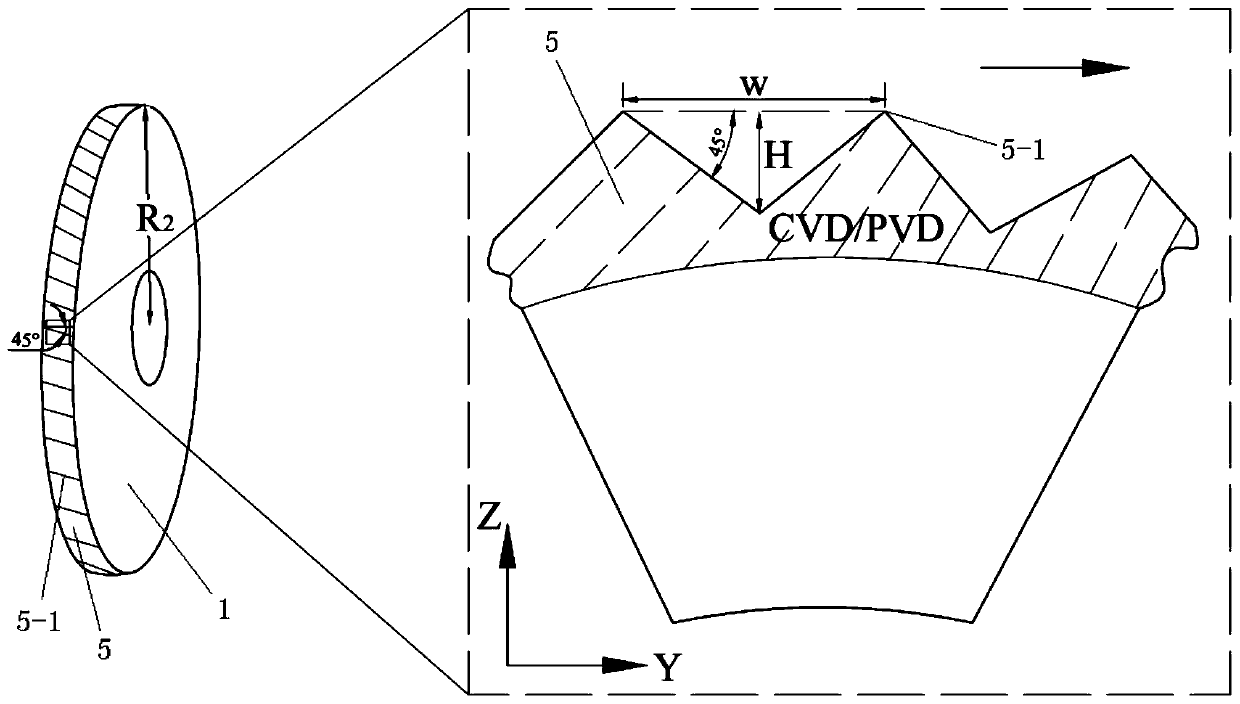

[0026] Specific embodiment one: combination figure 1 , figure 2 , image 3 To explain this embodiment, this embodiment provides an ultra-precision machining tool for a complex optical surface of monocrystalline silicon. The machining tool 1 is in the shape of a disc, and the radius of the disc is R 2 ; The side circumference of the processing tool is a 180° fillet, and the fillet radius is R 1 ,Such as figure 2 Shown; the processing tool is provided with a through hole at the center of the circle, the through hole is used to mount the processing tool 1 to the rotating shaft 2 of the processing machine, R 1 Smaller than the minimum radius of curvature r of the surface structure of the single crystal silicon optically complex surface element 3 1 ; R 2 Smaller than the minimum curvature radius r on the single crystal silicon optically complex surface element 3 1 The minimum radius of curvature r in the other direction perpendicular to the direction 2 ;Such as image 3 As shown, the ...

specific Embodiment approach 2

[0041] Specific embodiment two: this embodiment is different from specific embodiment one in that the side surface of the processing tool is provided with a CVD or PVD diamond thin film coating with a thickness of 3-5 μm; the CVD means chemical vapor deposition ( Chemical Vapor Deposition), the PVD stands for Physical Vapor Deposition.

[0042] The other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination figure 1 , Figure 4 , Figure 5 To describe this embodiment, the ultra-precision processing method for the optically complex surface of single crystal silicon provided in this embodiment specifically includes the following steps:

[0044] Step 1. Install the processing tool on the rotating shaft of the processing machine with an installation error of less than 1μm; install the trial-machined part horizontally on the worktable; use the processing tool to perform trial-processing on the trial-machined part, using radial feed and shaft Two cross-arc grooves are machined on the surface of the trial-machined part by the forward feeding method; the axial direction refers to the direction of the rotation axis of the processing machine tool, and the radial refers to the direction of the rotation axis of the processing machine The direction perpendicular and parallel to the horizontal plane; after trial processing, the surface accurac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com