Preparation method of silicon dioxide

A silicon dioxide and slag technology, which is applied in the field of silicon dioxide preparation, can solve problems such as the difficulty of finding silicon sources, and achieve the effects of environmental friendliness, reduced production costs, and high extraction content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

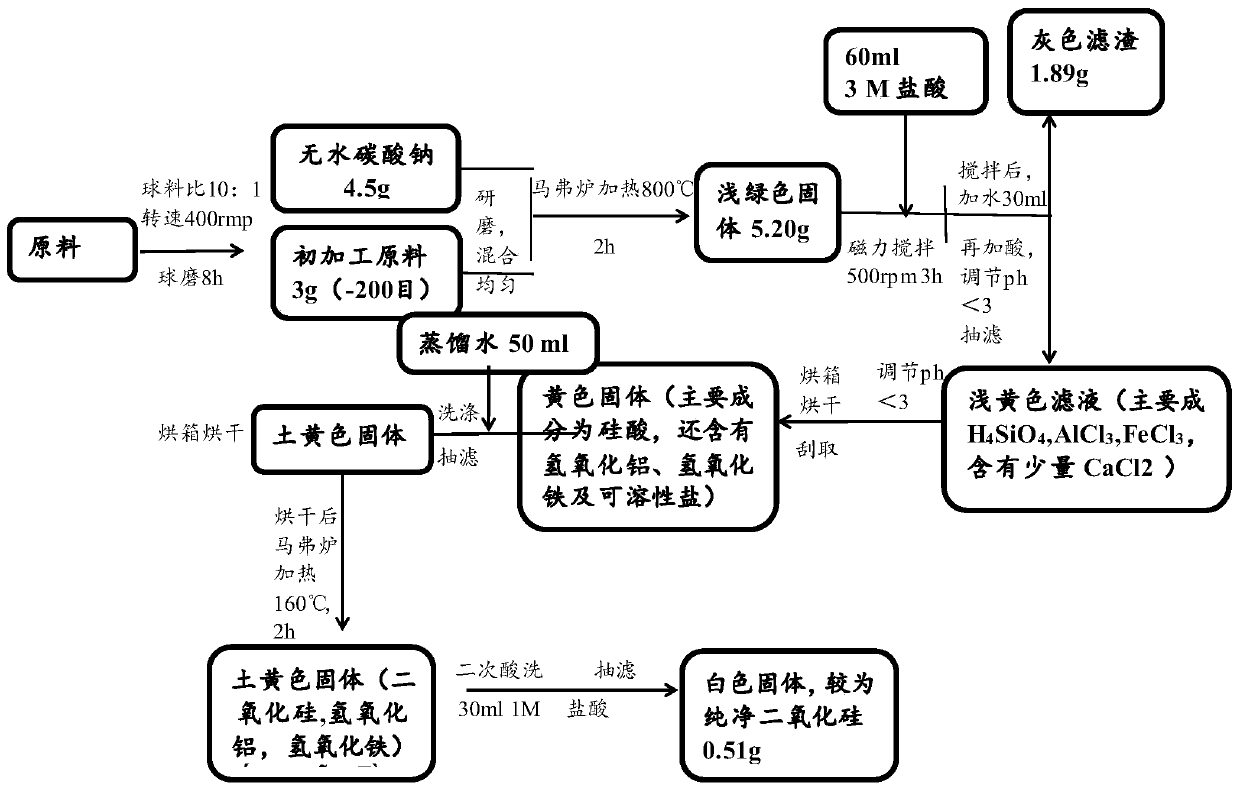

[0025] The invention provides a method for preparing silicon dioxide, comprising:

[0026] S1) mixing the slag with carbonate and reacting at high temperature to obtain a first intermediate product; the slag is slag containing silicon dioxide;

[0027] S2) After mixing the first product with an acid solution for acid leaching, filtering to obtain a filtrate;

[0028] S3) drying the filtrate to obtain a second intermediate product;

[0029] S4) Calcining the second intermediate product and washing it with acid to obtain silicon dioxide.

[0030] The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0031] Wherein, the slag material is one or more of molybdenum slag, steel slag and furnace slag well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably molybdenum slag, blast furnace slag discarded from steelmaking, One or more of conve...

Embodiment 1

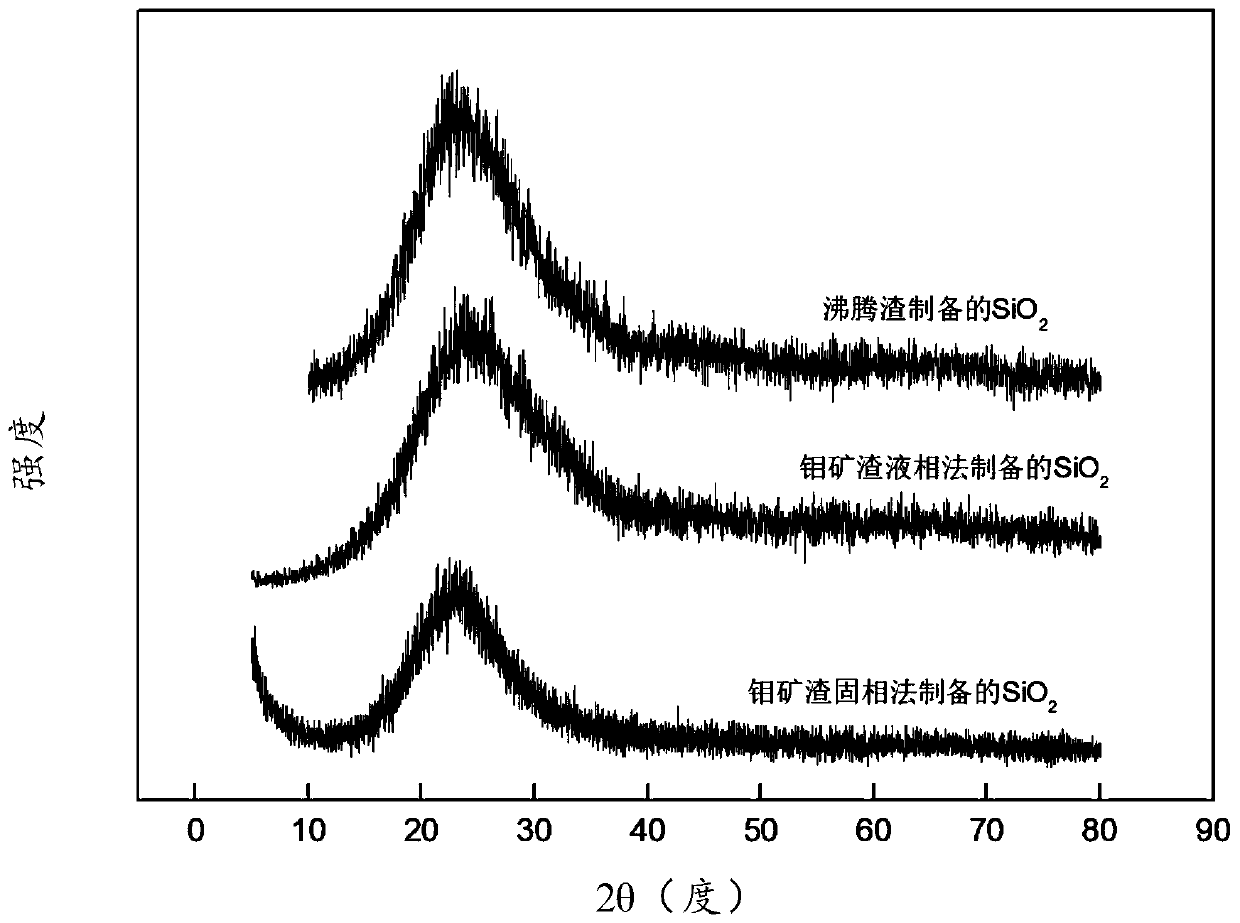

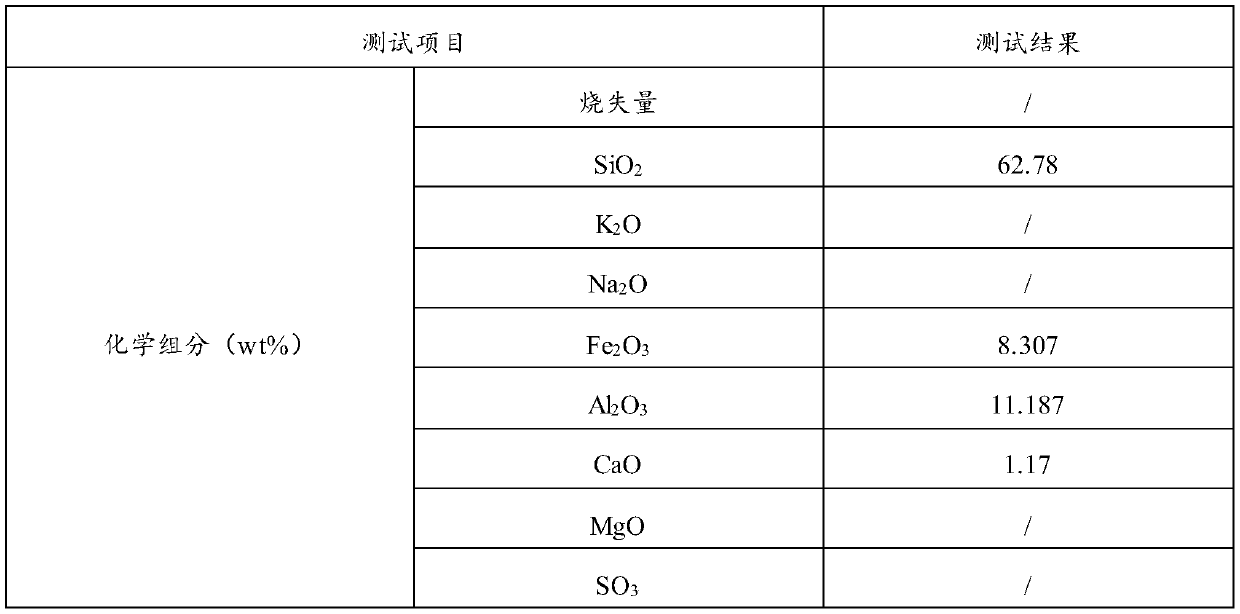

[0053] Using molybdenum slag as raw material, the composition of the molybdenum slag is shown in Table 1.

[0054] Table 1 Composition of molybdenum slag

[0055]

[0056] 1.1 Ball mill the molybdenum slag for 8 hours with a ball-to-material ratio of 10:1 and a speed of 400 rpm to obtain raw materials with a particle size of less than 200 mesh.

[0057] 1.2 Grind and mix 4.5g of the raw material obtained in 1.1 with 4.5g of anhydrous sodium carbonate, place in a muffle furnace at 800°C for 2h at high temperature, and obtain 5.2g of a light green solid.

[0058] 1.3 Mix the light green solid obtained in 1.2 with 60ml of 3mol / L hydrochloric acid for acid leaching. The acid leaching is carried out under magnetic stirring at a stirring speed of 500rpm. After 3 hours, add 30ml of water, then add acid to adjust the pH value to less than 3, and filter with suction , to obtain gray filter residue and light yellow filtrate (main component H 4 SiO 4 , AlCl 3 , FeCl 3 , containin...

Embodiment 2

[0066] Prepare according to the method of Example 1, the difference is that the raw material after 2g ball milling is ground and mixed with 2.4g anhydrous sodium carbonate, the mass ratio of raw material and anhydrous sodium carbonate is 1: 1.2, finally obtains 0.42g silicon dioxide, purity More than 93%, the yield is 31.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com