Carbon dioxide gas recovery system

A gas recovery, carbon dioxide technology, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as increasing the greenhouse effect, and achieve the effect of wide application range, simple operation, and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

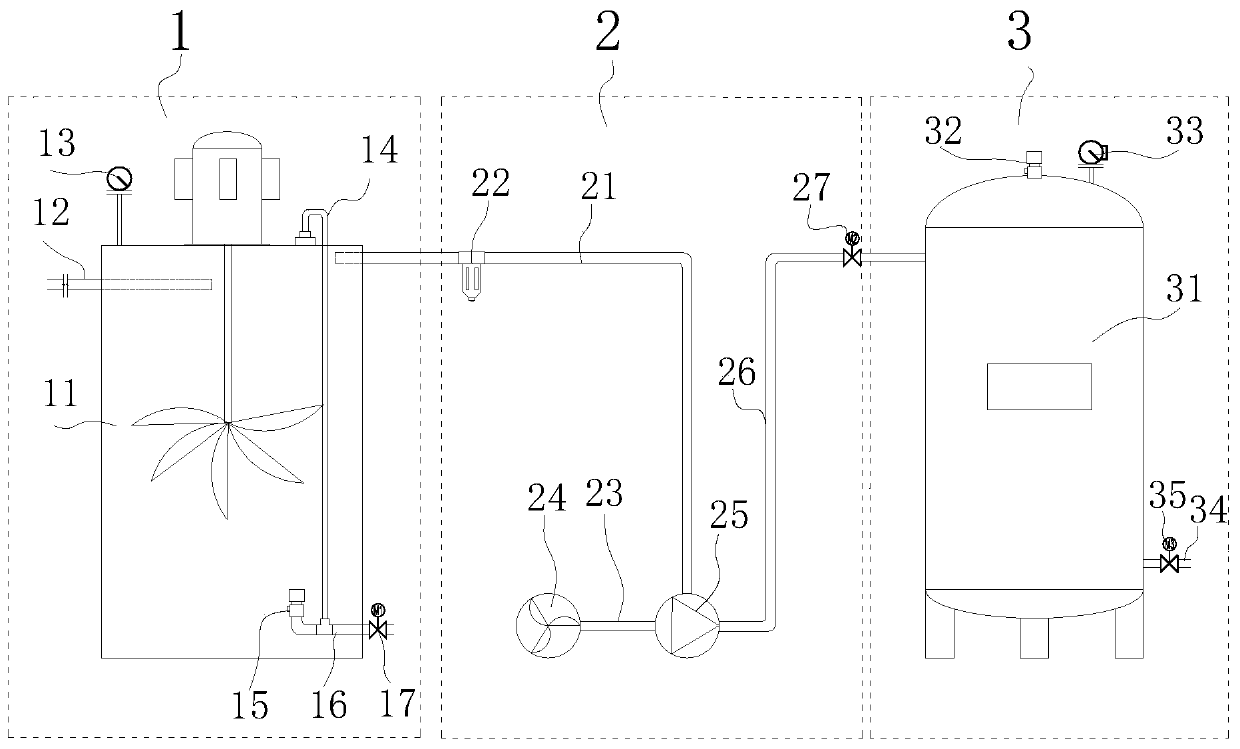

[0023] Such as figure 1 Shown, a carbon dioxide gas recovery system, including

[0024] A water-gas separation system 1, the water-gas separation system is composed of a water-gas separation tank 11, a water inlet pipe 12, a stirring mechanism and a safety drainage device thereof, the water inlet pipe 12 and the water inlet pipe 12 are connected to the water-gas separation tank 11 upper end of the side wall Water port communicates, and communicates with the inside of water-gas separation tank 11, and described agitation mechanism is made of driving assembly 15 and the executive assembly 16 that is located at the driving end of driving assembly 15, and driving assembly 15 is installed on the upper end of water-gas separation tank 11, executes The assembly 16 runs through the water-gas separation tank 11 and extends to the inside of the water-gas separation tank 11. The safety drainage device is installed on the water-gas separation tank 11, and the drain end where the exhaust d...

Embodiment 2

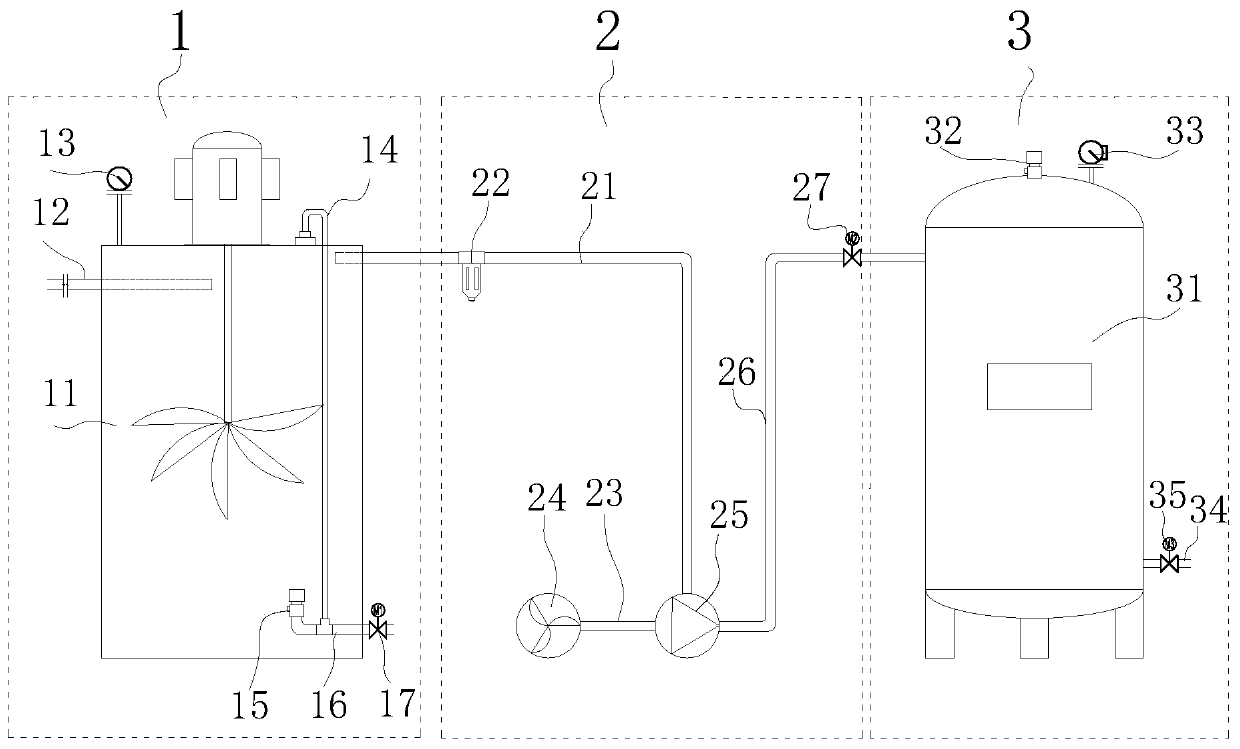

[0028] Such as figure 1 Shown, a carbon dioxide gas recovery system, including

[0029] A water-gas separation system 1, the water-gas separation system is composed of a water-gas separation tank 11, a water inlet pipe 12, a stirring mechanism and a safety drainage device thereof, the water inlet pipe 12 and the water inlet pipe 12 are connected to the water-gas separation tank 11 upper end of the side wall Water port communicates, and communicates with the inside of water-gas separation tank 11, and described agitation mechanism is made of driving assembly 15 and the executive assembly 16 that is located at the driving end of driving assembly 15, and driving assembly 15 is installed on the upper end of water-gas separation tank 11, executes The assembly 16 runs through the water-gas separation tank 11 and extends to the inside of the water-gas separation tank 11. The safety drainage device is installed on the water-gas separation tank 11, and the drain end where the exhaust d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap