Aluminum oxide ceramic heating tube and preparation method thereof

An alumina ceramic tube and alumina ceramic technology, which is applied in the shape of heating elements and ohmic resistance heating parts, can solve the problems of shortening the service life of kiln refractories, high firing temperature, lattice distortion, etc. Thermal conductivity, rapid and uniform temperature rise, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

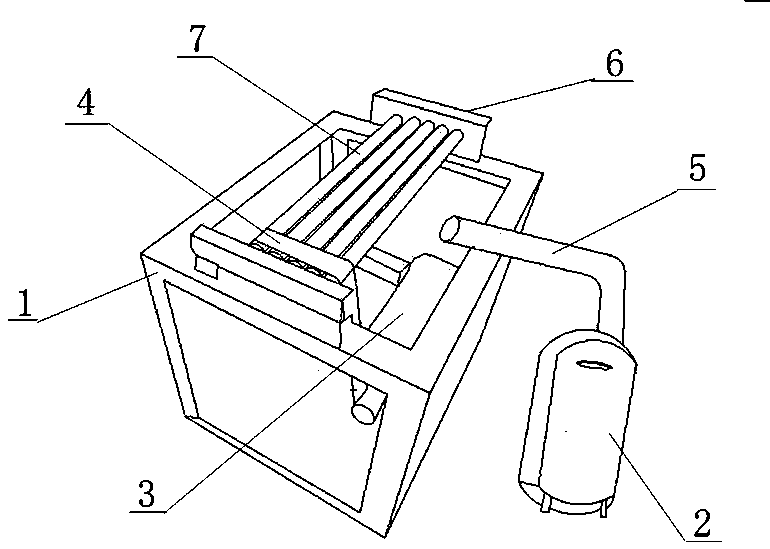

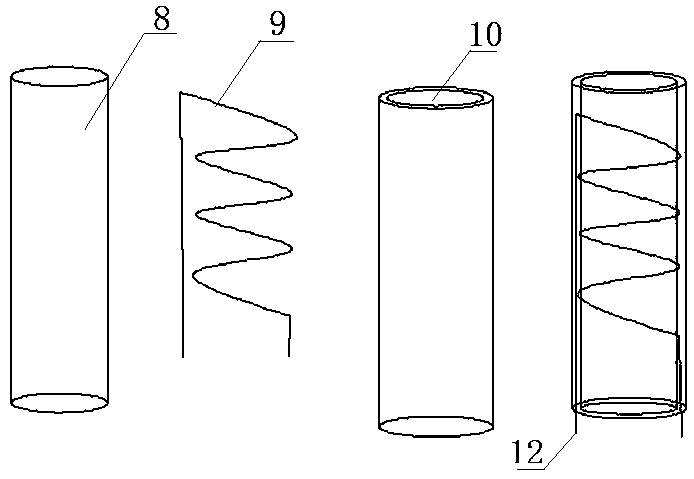

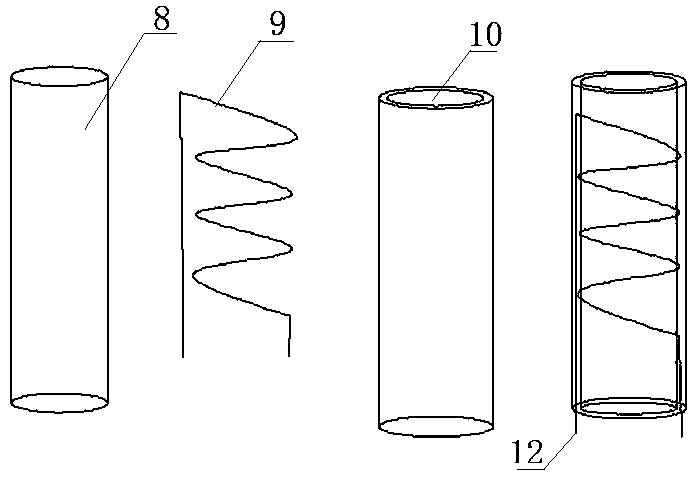

[0028] An alumina ceramic heating tube, comprising an alumina ceramic tube, a silica gel layer, an electric heating tungsten wire, and a silver wire, the silica gel layer 8 is arranged on the outer surface of the alumina ceramic pipe 10, and the electric heating tungsten wire 9 is arranged on the silica gel layer 8 Between the aluminum oxide ceramic tube 10, silver wires 12 are arranged at both ends of the electric heating tungsten wire 9.

[0029] The alumina ceramic tube has a thickness of 0.3mm and a density of 3.9g / cm 3 , the resistance is 0.6Ω; the thickness of the silica gel layer is 1.9mm, and the temperature resistance is 350°C; the thickness of the electric heating tungsten wire is 0.05mm, and the diameter of the silver wire is 0.1 mm.

[0030]The preparation method of the heating tube includes the following steps:

[0031] Preparation of step-alumina ceramic tube mud: add in 100 parts of nano-alumina powder by weight percentage, 0.04 part of Mg(NO 3 ) 2 6H 2 O, ...

Embodiment 2

[0040] An alumina ceramic heating tube, comprising an alumina ceramic tube, a silica gel layer, an electrothermal nickel wire, and a silver wire, the silica gel layer 8 is arranged on the outer surface of the alumina ceramic tube 10, and the electrothermal nickel wire 9 is arranged on the silica gel layer 8 Between the aluminum oxide ceramic tube 10, silver wires 12 are arranged at both ends of the electric heating nickel wire 9.

[0041] The alumina ceramic tube has a thickness of 0.4mm and a density of 3.9g / cm 3 , the resistance is 0.8Ω; the thickness of the silica gel layer is 1.5mm, and the temperature resistance is 340°C; the thickness of the electrothermal nickel wire is 0.04mm, and the diameter of the silver wire is 0.14mm.

[0042] The preparation method of the heating tube includes the following steps:

[0043] Preparation of step-alumina ceramic tube mud: add in 100 parts of nano-alumina powder by weight percentage, 0.02 part of Mg(NO 3 ) 2 6H 2 O, 0.03 parts of...

Embodiment 3

[0052] An alumina ceramic heating tube, comprising an alumina ceramic tube, a silica gel layer, an electric heating tungsten wire, and a silver wire, the silica gel layer 8 is arranged on the outer surface of the alumina ceramic pipe 10, and the electric heating tungsten wire 9 is arranged on the silica gel layer 8 Between the aluminum oxide ceramic tube 10, silver wires 12 are arranged at both ends of the electric heating tungsten wire 9.

[0053] The alumina ceramic tube has a thickness of 0.5mm and a density of 3.9g / cm 3 , the resistance is 1.5Ω; the thickness of the silica gel layer is 1.2 mm, and the temperature resistance is 390° C.; the thickness of the electric heating tungsten wire is 0.03 mm, and the diameter of the silver wire is 0.19 mm.

[0054] The preparation method of the heating tube includes the following steps:

[0055] Preparation of step-alumina ceramic tube mud: add in 100 parts of nano-alumina powder by weight percentage, 0.03 part of Mg(NO 3 ) 2 6H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com