Special water-based paint for containers and preparation method of water-based paint

A water-based paint and container technology, applied in the field of coatings, can solve problems such as blooming, poor adhesion and water resistance, and achieve the effects of improving adhesion, improving anti-rust performance, and solving blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

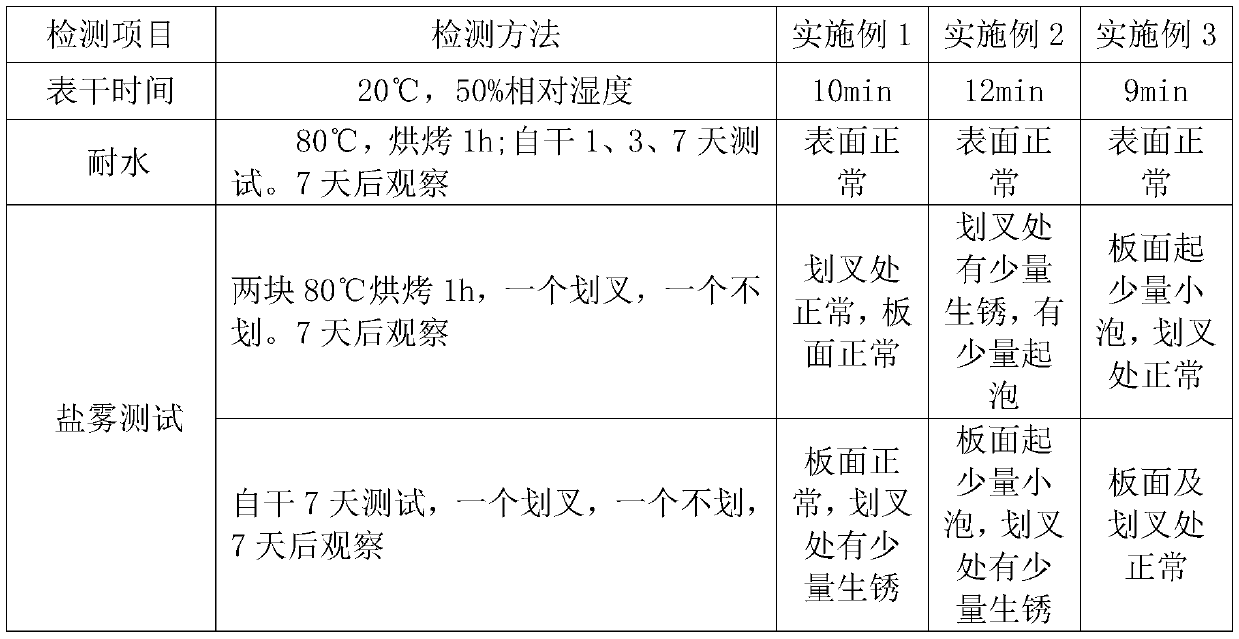

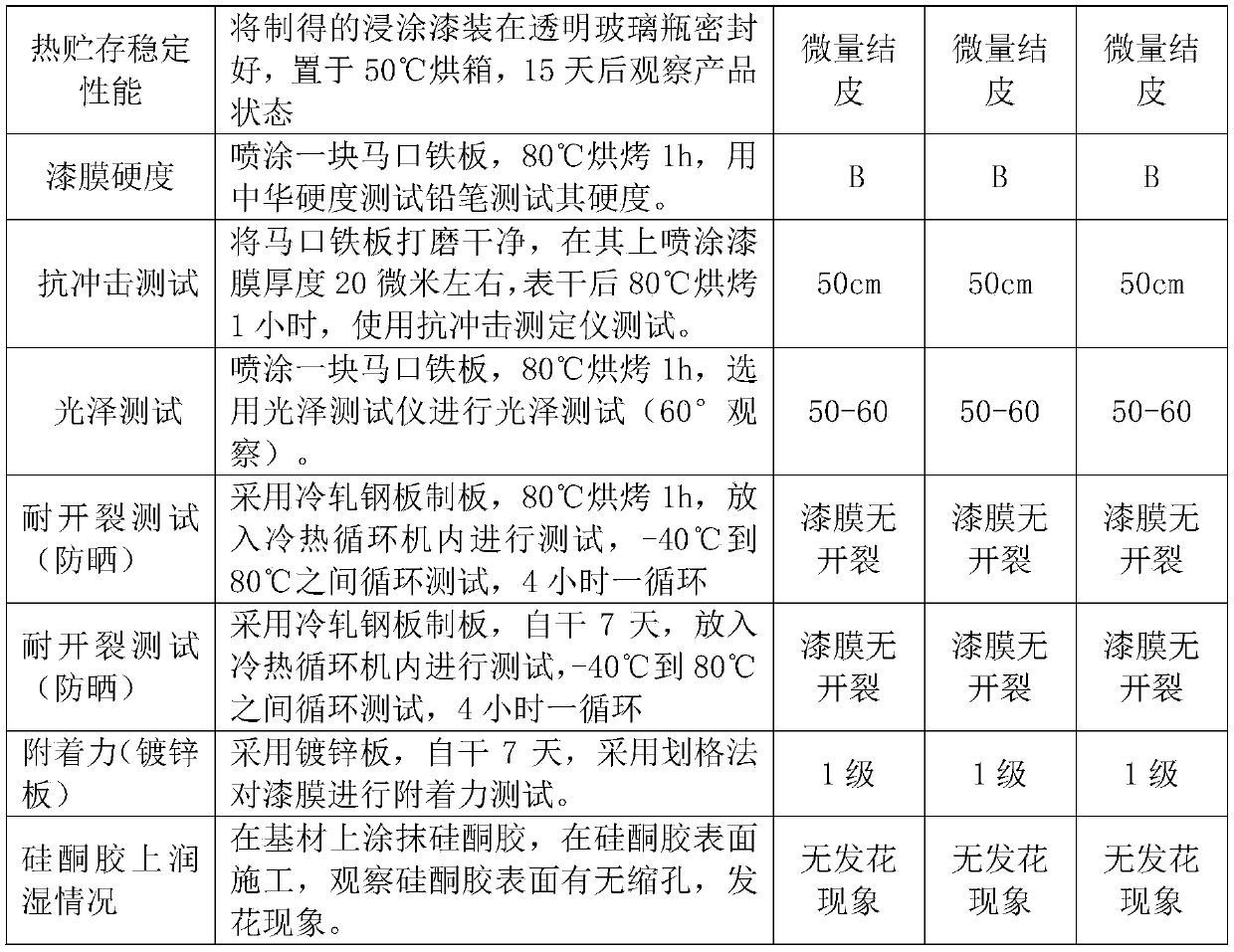

Examples

Embodiment 1

[0025] A special water-based paint for containers, comprising the following components in parts by weight: 60 parts of water-based acrylic emulsion, 10 parts of deionized water, 0.7 parts of antifreeze, 0.5 parts of neutralizing agent, 1 part of dispersant, 0.2 parts of defoamer, 5 parts of film-forming aid, 0.1 part of fungicide, 5 parts of pigment, 1 part of anti-flash rust agent, 0.5 part of wetting and leveling agent, 3 parts of dust-proof thixotropic agent, and 3 parts of thickener.

[0026] Wherein: the water-based acrylic emulsion is XG2000 of Hengshui Xinguang; the solvent is ethylene glycol; the neutralizer is dimethylethanolamine, the dispersant is BYK190 of BYK, and the defoamer is BYK BYK024, the dust-proof thixotropic agent is organic bentonite (mass fraction is 3%, prepared with water); the wetting and leveling agent is TEGO100; the film-forming aid is alcohol ester 12; the antifreezing agent is propylene glycol; The bactericide is K9N, the pigment is phthalocyan...

Embodiment 2

[0032] A special water-based paint for containers, comprising the following components in parts by weight: 40 parts of water-based acrylic emulsion, 8 parts of deionized water, 0.5 parts of antifreeze, 0.4 parts of neutralizing agent, 0.5 parts of dispersant, 0.1 part of defoamer, 3 parts of film-forming aid, 0.05 part of fungicide, 4 parts of pigment, 0.5 part of anti-flash rust agent, 0.4 part of wetting and leveling agent, 2 parts of dust-proof thixotropic agent, and 2 parts of thickener.

[0033] Wherein: the water-based acrylic emulsion is XG2000 of Hengshui Xinguang; the solvent is ethylene glycol; the neutralizer is dimethylethanolamine, the dispersant is BYK190 of BYK, and the defoamer is BYK BYK024, the dust-proof thixotropic agent is organic bentonite (mass fraction is 3%, prepared with water); the wetting and leveling agent is TEGO100; the film-forming aid is alcohol ester 12; the antifreezing agent is propylene glycol; The bactericide is K9N, the pigment is phthalo...

Embodiment 3

[0039] A special water-based paint for containers, comprising the following components in parts by weight: 50 parts of water-based acrylic emulsion, 12 parts of deionized water, 0.9 parts of antifreeze, 0.6 parts of neutralizing agent, 1.5 parts of dispersant, 0.3 parts of defoamer, 7 parts of film-forming aids, 0.15 parts of fungicides, 6 parts of pigments, 1.5 parts of anti-flash rust agents, 0.6 parts of wetting and leveling agents, 4 parts of dust-proof thixotropic agents, and 4 parts of thickeners.

[0040] Wherein: the water-based acrylic emulsion is XG2000 of Hengshui Xinguang; the solvent is ethylene glycol; the neutralizer is dimethylethanolamine, the dispersant is BYK190 of BYK, and the defoamer is BYK BYK024, the dust-proof thixotropic agent is organic bentonite (mass fraction is 3%, prepared with water); the wetting and leveling agent is TEGO100; the film-forming aid is alcohol ester 12; the antifreezing agent is propylene glycol; The bactericide is K9N, the pigmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap