mg 2+ /ge 4+ replace ga 3+ doped cr 3+ Zinc gallate-based near-infrared long afterglow material and preparation method

A technology of zinc gallate and outer length, which is applied in the field of material science, can solve the problems of insufficient luminous intensity and afterglow time for long-term observation, coarse particles, and difficulty entering the living body, etc., and achieves low cost, simple operation, and excellent uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

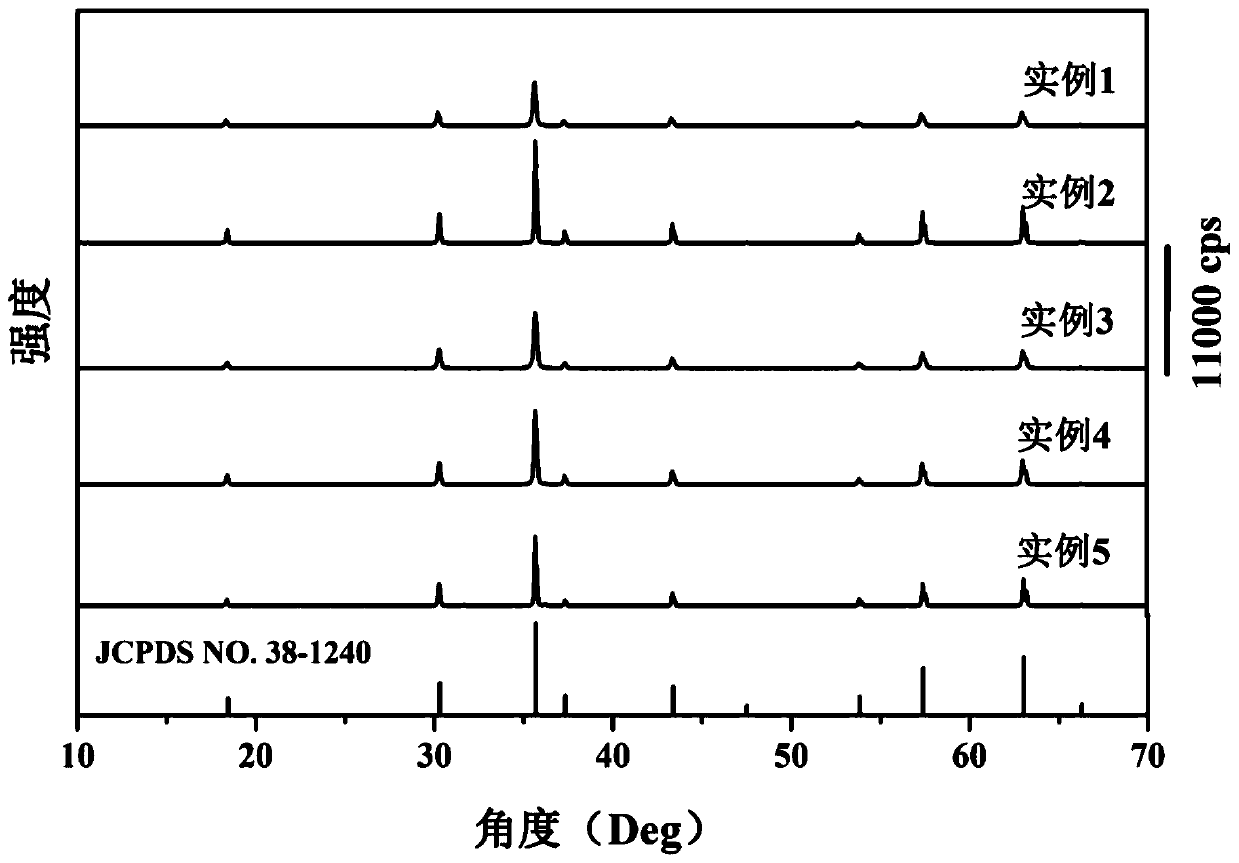

[0029] Embodiment 1 (x=0.01, y=0.01)

[0030] Accurately weigh 1.7536g EDTA and 0.0012g GeO 2 Put it into a beaker, add an appropriate amount of deionized water, start stirring, then add 5mL of ammonia water according to experience, and accurately measure 2mL of Zn(NO 3 ) 2 solution (1mol / L), 9.9mL of Ga(NO 3 ) 3 solution (0.4mol / L), 0.05mL of Mg(NO 3 ) 2 solution (0.2mol / L) and 0.2mL of Cr(NO 3 ) 3 solution (0.1mol / L), add deionized water to 50mL while stirring. The above solution was transferred to a water bath and stirred at a water temperature of 70 °C until the GeO 2 Completely dissolved, and distilled in water for 5 hours until the water evaporated, the solution formed a gel state. Take out the beaker, transfer the gel to an oven, and bake at 180°C for 6 hours to obtain ZnGa 1.99 (Mg 2+ / Ge 4+ ) 0.01 o 4 :0.01Cr 3+ Black precursor powder. After grinding the above precursors, they were calcined at 700°C for 5 hours in a flowing oxygen atmosphere to obtain ...

Embodiment 2

[0031] Embodiment 2 (x=0.5, y=0.05)

[0032] Accurately weigh 2.6304g EDTA and 0.0523gGeO 2 Add deionized water, accurately measure 2mL Zn(NO 3 ) 2 Solution (1mol / L), 7.25mL Ga(NO 3 ) 3 solution (0.4mol / L), 2.5mL Mg(NO 3 ) 2solution (0.2mol / L) and 1mL Cr(NO 3 ) 3 solution (0.1mol / L), added to the solution, and ammonia water was added dropwise until clarification. The above solution was transferred to a water bath, and stirred for 7 h at a water temperature of 80° C. to form a gel. Take out the beaker, transfer the gel to an oven, and bake at 300°C for 2 hours to obtain ZnGa 1.5 (Mg 2 + / Ge 4+ ) 0.5 o 4 :0.05Cr 3+ Black precursor powder. After the above precursor is ground, it is calcined at 1000°C for 2 hours in a flowing oxygen atmosphere to obtain the near-infrared long-lasting fluorescent material ZnGa 1.5 (Mg 2+ / Ge 4+ ) 0.5 o 4 :0.05Cr 3+ .

Embodiment 3

[0033] Embodiment 3 (x=1, y=0.005)

[0034] Accurately weigh 3.5069g EDTA and 0.1046g GeO 2 Add deionized water, accurately measure 2mL Zn(NO 3 ) 2 Solution (1mol / L), 7.465mL Ga(NO 3 ) 3 solution (0.4mol / L), 5mL Mg(NO 3 ) 2 solution (0.2mol / L) and 0.01mLCr(NO 3 ) 3 solution (0.1mol / L), added to the solution, and ammonia water was added dropwise until clarification. The above solution was transferred to a water bath, and stirred at a water temperature of 85° C. for 6 h to form a gel. Take out the beaker, transfer the gel to an oven, and bake at 230°C for 3 hours to obtain ZnGa(Mg 2 + / Ge 4+ )O 4 :0.005Cr 3+ Black precursor powder. After the above precursors were ground, they were calcined at 1400 °C for 4 h in a flowing oxygen atmosphere to obtain the near-infrared long-lasting fluorescent material ZnGa(Mg 2+ / Ge 4+ )O 4 :0.005Cr 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com