Production method of crude white oil product

A production method and white oil technology, which are applied in the fields of hydrocarbon oil treatment products, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of application of difficult and crude white oil products, dark color of products, etc., to achieve high economic added value and increase diversity , the effect of high overall economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

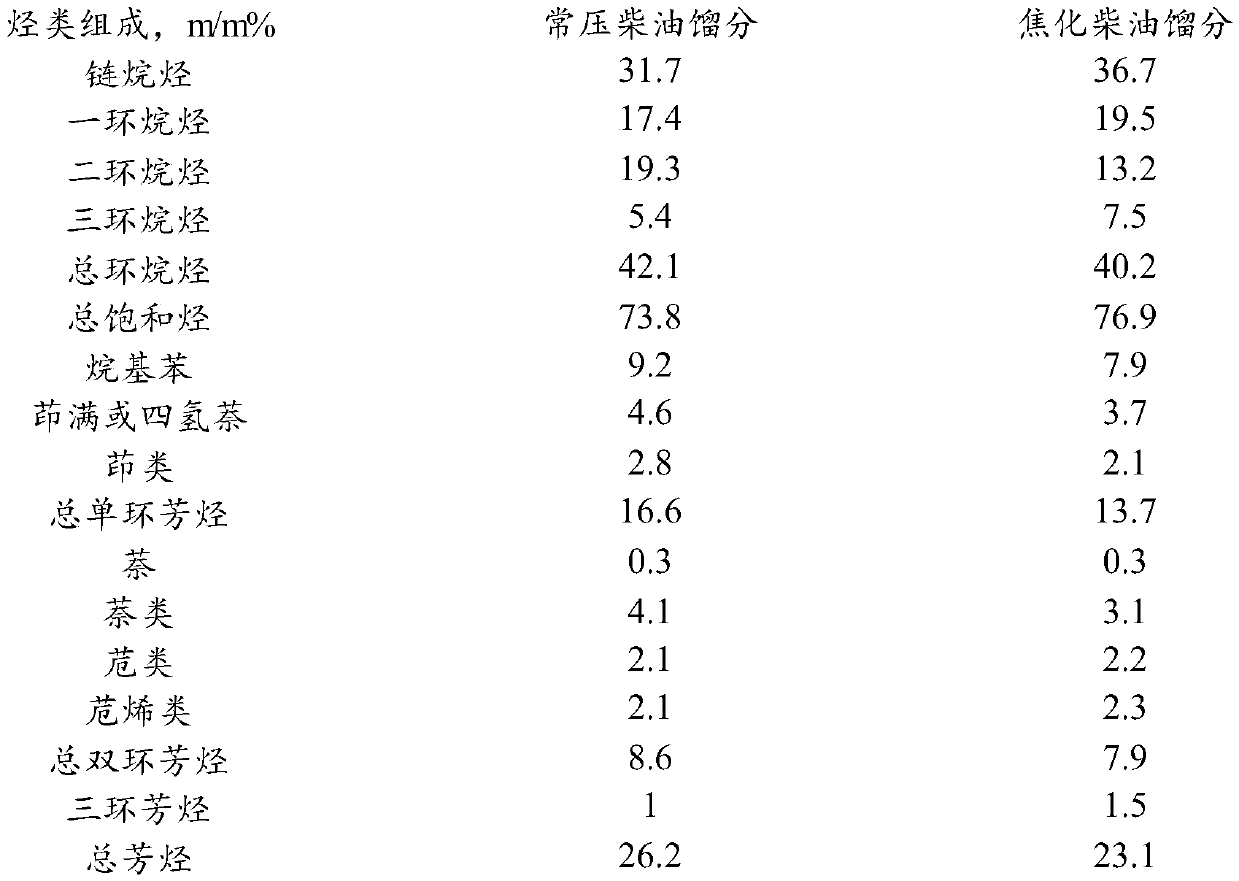

Method used

Image

Examples

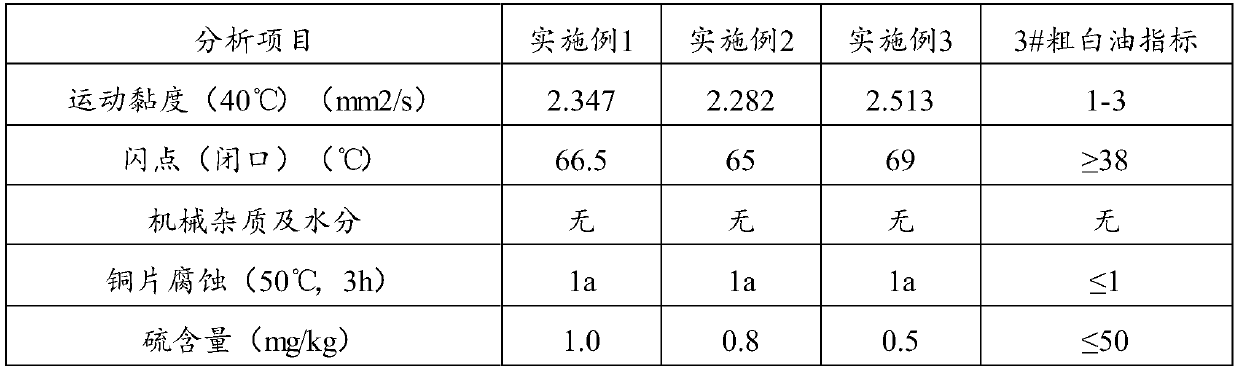

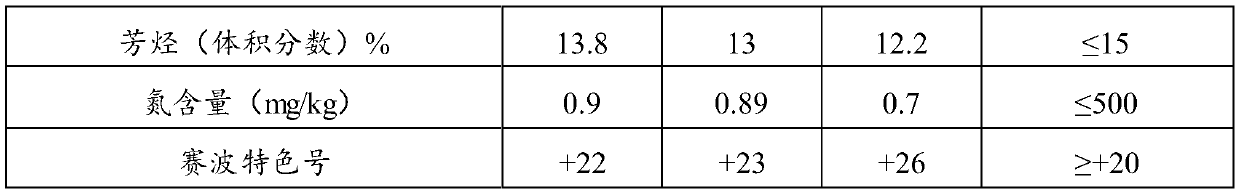

Embodiment 1

[0099] (1) The raw material oil is filtered through a filter and then enters the raw material oil buffer tank, then is boosted by a hydrogenation feed pump and mixed with hydrogen, and then enters the reaction feed heating furnace to be heated to the first reactor after heat exchange by a heat exchanger The inlet temperature is 310°C, enter the first reactor for refining reaction; the pressure of the refining reaction is 10MPa-12MPa, the temperature is 330°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; a refined reaction product is obtained.

[0100] (2) Put the refined reaction product obtained in step (1) directly into the second reactor for modification reaction; the pressure of the modification reaction is 10.5MPa~12.5MPa, the temperature is 340°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; the modified reaction product is obt...

Embodiment 2

[0103] (1) The raw material oil is filtered through a filter and then enters the raw material oil buffer tank, then is boosted by a hydrogenation feed pump and mixed with hydrogen, and then enters the reaction feed heating furnace to be heated to the first reactor after heat exchange by a heat exchanger The inlet temperature is 310°C, enter the first reactor for refining reaction; the pressure of the refining reaction is 10MPa-12MPa, the temperature is 340°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; a refined reaction product is obtained.

[0104] (2) Put the refined reaction product obtained in step (1) directly into the second reactor for modification reaction; the pressure of the modification reaction is 10.5MPa~12.5MPa, the temperature is 350°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; the modified reaction product is obt...

Embodiment 3

[0107] (1) The raw material oil is filtered through a filter and then enters the raw material oil buffer tank, then is boosted by a hydrogenation feed pump and mixed with hydrogen, and then enters the reaction feed heating furnace to be heated to the first reactor after heat exchange by a heat exchanger The inlet temperature is 310°C, and it enters the first reactor for refining reaction; the pressure of the refining reaction is 10MPa-12MPa, the temperature is 335°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; a refined reaction product is obtained.

[0108] (2) Put the refined reaction product obtained in step (1) directly into the second reactor for modification reaction; the pressure of the modification reaction is 10.5MPa~12.5MPa, the temperature is 345°C, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (1000-1300): 1; the modified reaction produc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap