Method for preparing immobilized cellulase

A cellulase and product technology, applied in the field of immobilized cellulase prepared by physical adsorption, can solve the problems of enzyme structure change, achieve stable properties, increase aroma components, and reduce nicotine effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

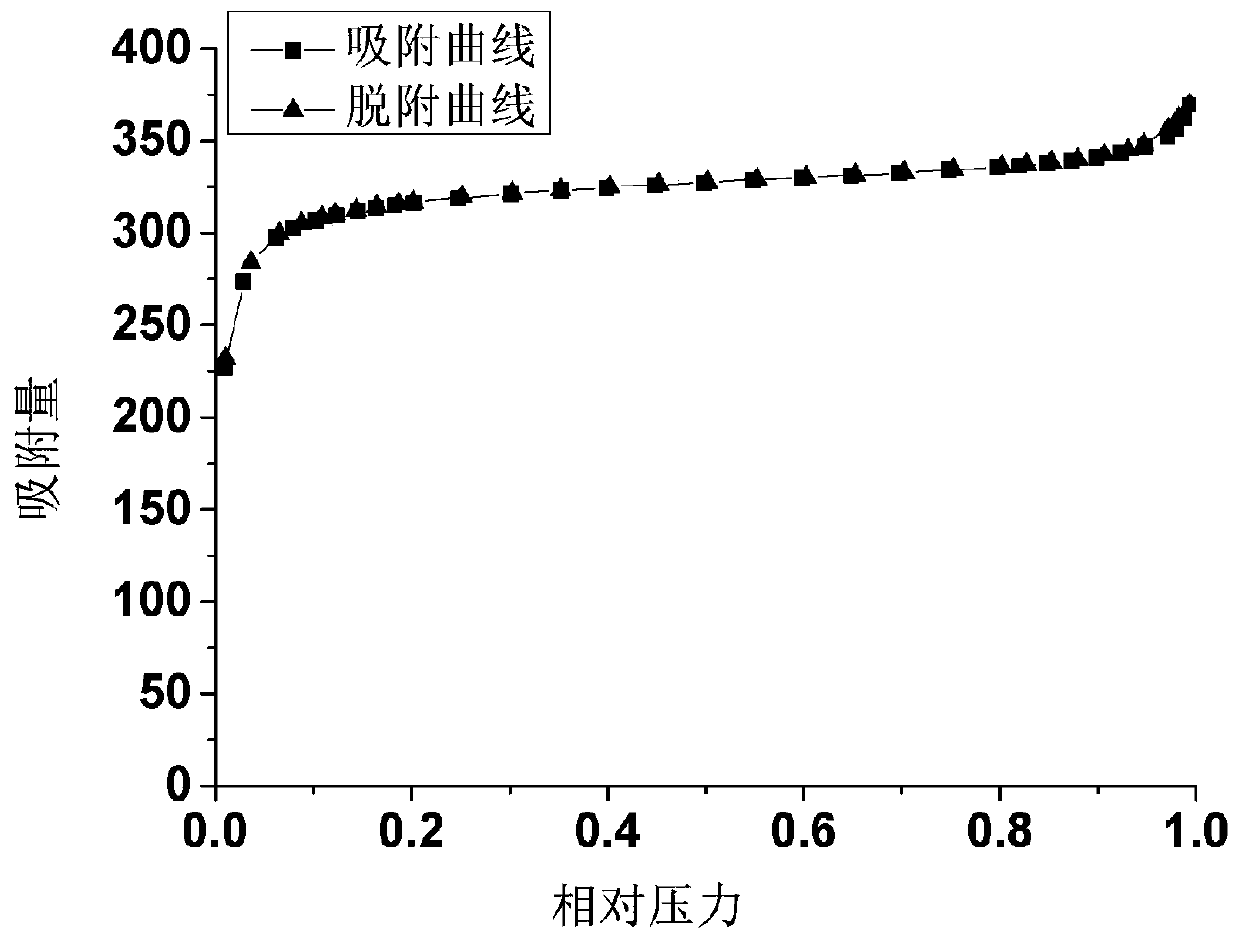

[0035] Preparation of immobilized cellulase: Weigh 100 mg of UiO-66 MOFs material into a test tube, add 100 mg of cellulase and 10 mL of water, mix well, place it in a 30°C water bath for oscillating adsorption for 5 hours, and obtain an oscillating product. Centrifuge the oscillating product twice, collect and combine the supernatant to obtain the centrifuged supernatant, wash the centrifuged precipitate three times with ultrapure water to obtain the centrifuged product, and dry the centrifuged product in a 30°C oven to obtain immobilized cellulase sample 1 .

[0036] The centrifuged supernatant was retained for measuring the cellulase loading rate, and the immobilized cellulase sample 1 was used for measuring the enzyme activity of the cellulase.

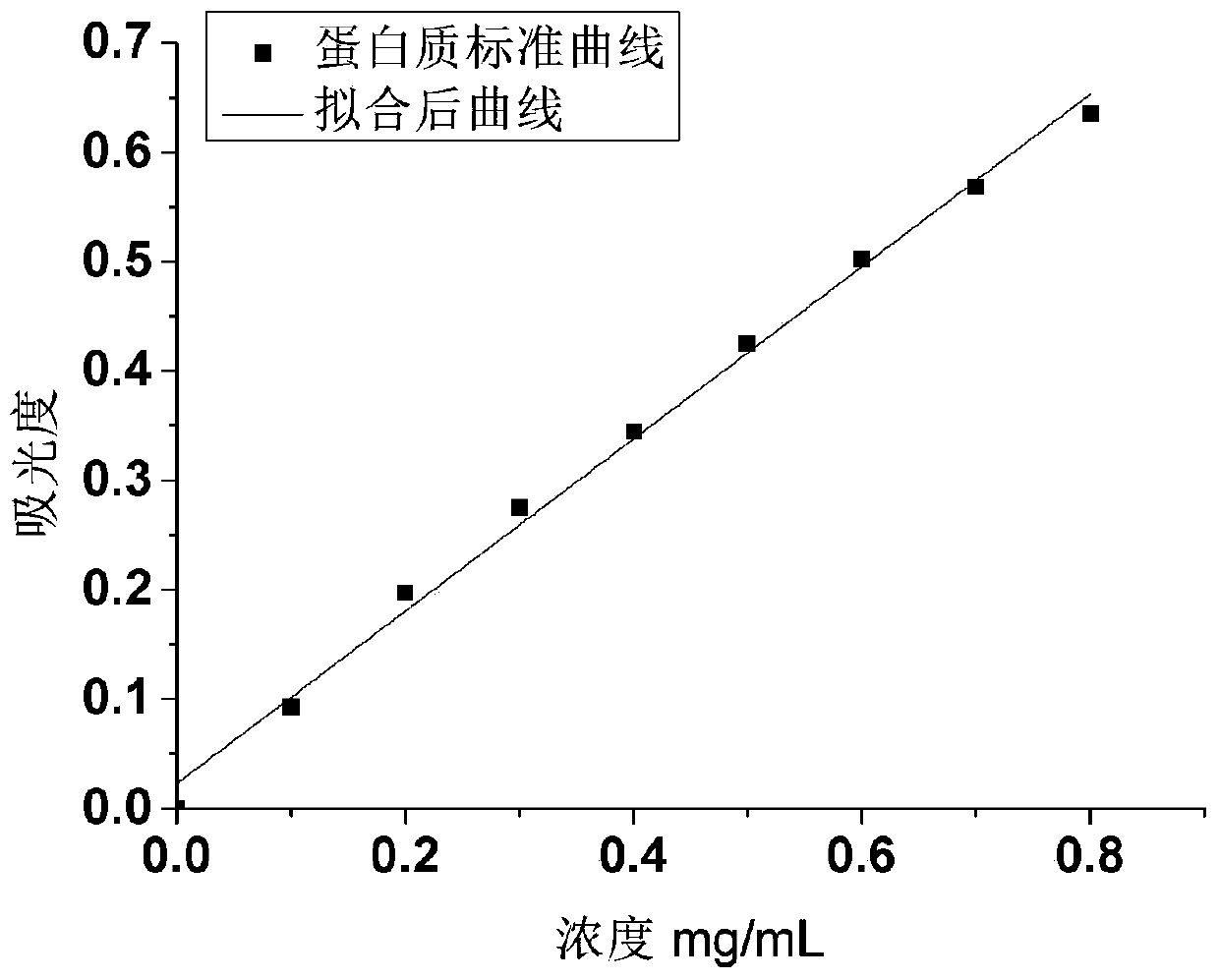

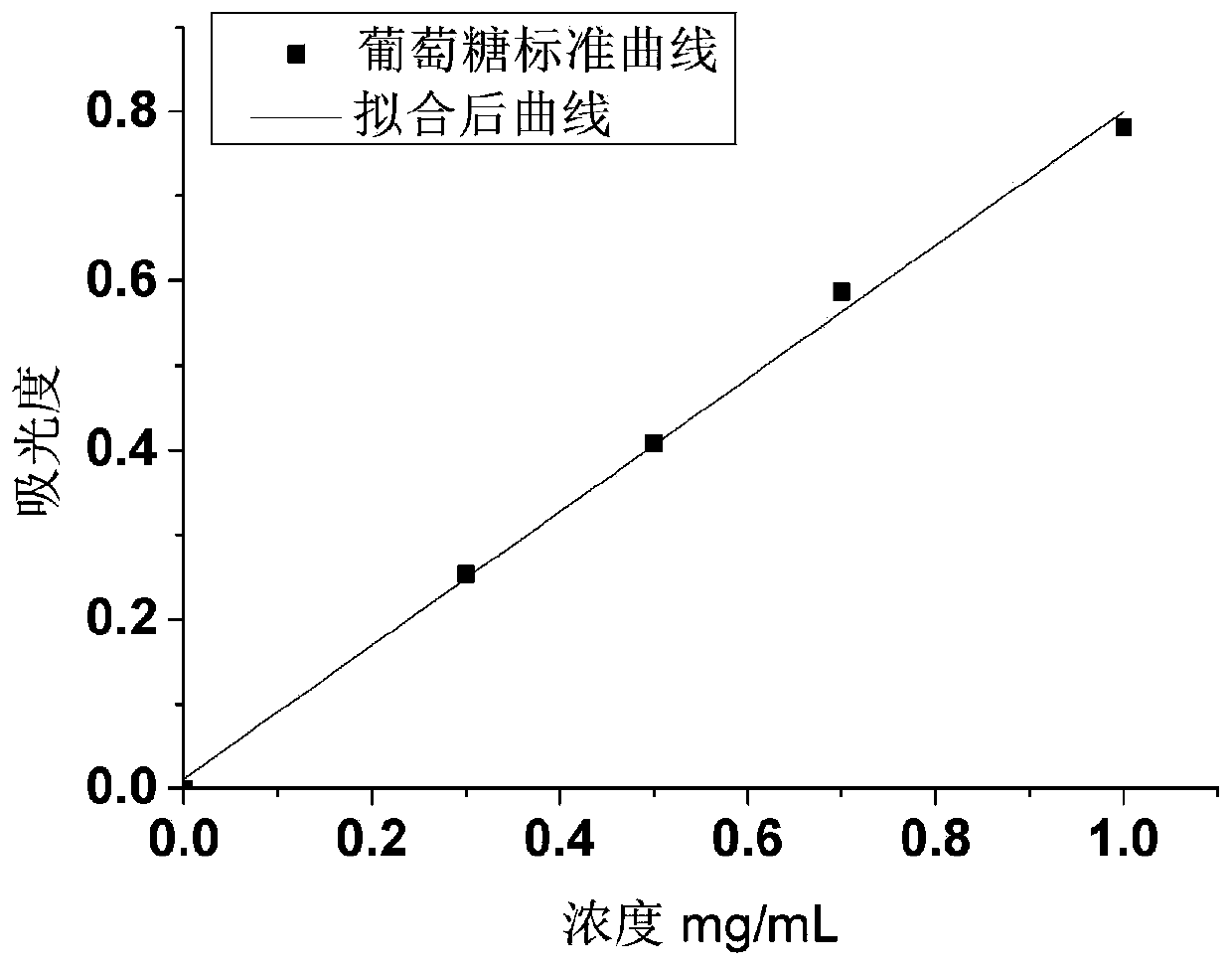

[0037] Determination of the loading rate of immobilized cellulase: Add 1mL of centrifuged supernatant and 1mL of water to two test tubes respectively, then add 5mL of staining solution to the test tubes, mix well, and wait for 5 m...

Embodiment 2

[0040] The preparation method of the immobilized cellulase was the same as that in Example 1, but the adsorption time was changed from 5 hours of adsorption in Example 1 to 7 hours of adsorption to obtain immobilized cellulase sample 2. The loading rate of immobilized cellulase and the enzyme activity of immobilized cellulase were measured under the same conditions.

Embodiment 3

[0042] The preparation method of the immobilized cellulase was the same as in Example 1, except that the adsorption time was changed, and the adsorption time in Example 1 was changed from 5 h to 9 h, and immobilized cellulase sample 3 was obtained. The other things were unchanged, and the loading rate of immobilized cellulase was measured under the same conditions, and the enzyme activity of immobilized cellulase was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com