A method to cope with the thermal load shock in the late stage of blast furnace operation

A heat load and blast furnace technology, applied in the direction of cooling devices, etc., can solve problems such as furnace skin crack expansion, furnace skin stress concentration, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

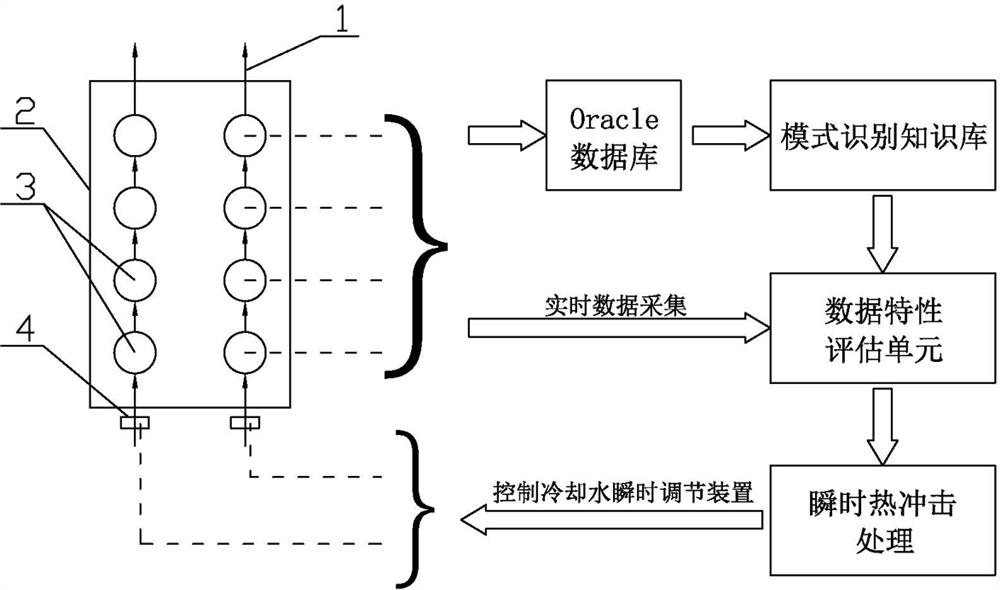

[0044] Depend on figure 1 It can be seen that a method to deal with the thermal load shock in the later stage of blast furnace operation includes the following steps:

[0045] ⑴Material lowering line: In the case of a large number of damaged staves, clean up the remaining stave wall, and lower the material line below the remaining stave elevation (in this embodiment, 3200m 3 Take the blast furnace as an example, the height of the shaft is 17.5m, the height of the bosh is 2m, and the height of the waist is 3m), so as to facilitate the installation and construction of the blast furnace cooling column 3;

[0046] (2) Furnace skin opening: according to the characteristics of the damaged area, use a drilling machine to make holes on the furnace skin around the damaged area. 3 The total thickness of the furnace skin and cooling wall of the blast furnace is 400㎜~500㎜), that is, the depth of the opening should be such that the cooling column 3 touches the furnace material after insta...

Embodiment 2

[0075] The cooling column group of this embodiment is a row of 4 cooling columns 3 on one block 2, a total of 8 cooling columns 3 in the left and right columns, and a total of 16 cooling columns 3 in two columns connected up and down adjacent to each other to form a cooling column. column group.

[0076] The rest are the same as embodiment 1.

Embodiment 3

[0078] The cooling column group of this embodiment is a row of 4 cooling columns 3 on one block 2, and three blocks 2 connected up and down successively are installed with a total of 12 cooling columns 3 in one column to form a cooling column group.

[0079] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com