Recovery and utilization device and method for waste lead paste in waste lead-acid storage batteries

A technology of waste lead-acid batteries and waste lead paste, which is applied in the direction of improving process efficiency, can solve the problems of large difference in catalytic activity, high desulfurization cost, easy to block pipelines, etc., to improve material utilization and yield, improve Product recovery and purity, and the effect of reducing experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the invention of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

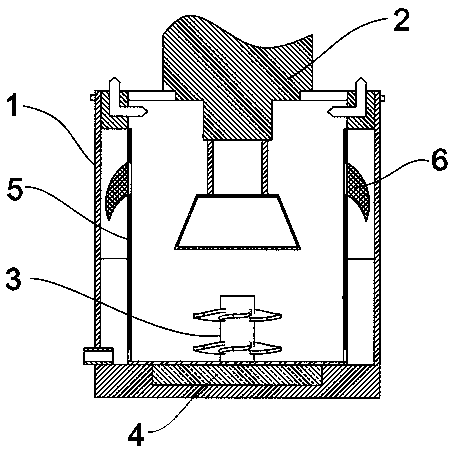

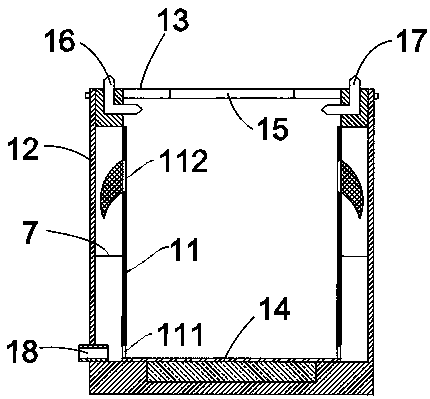

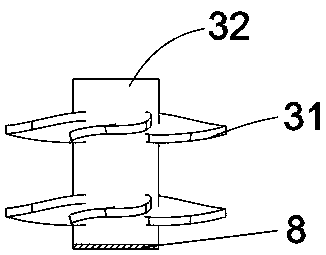

[0029] see Figure 1-5A recycling device for waste lead paste in waste lead-acid batteries is shown, including a reaction kettle 1, a porous round table filling cylinder 2, an impeller power element 3, a servo motor 4, an adhesive film 5, a crystallization filter 6 and a circulation communication system ; The reaction kettle 1 is a hollow double-layer straight-arm cylindrical structure, including an inner wall 11, an outer wall 12, a sealing glass cover 13 located at the top and an isolation layer 14 located at the bottom; Fixedly connected, the inner layer of the inner wall 11 is provided with an adhesive film 5 having the same shape as the inner wall, and the attached film 5 is used to collect the remaining precipitation and crystallization when the lower layer solution rotates; the sealing glass cover 13 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com