[0003] However, because of the particularity of the two-component material itself, as far as the construction of the two-component material (or multi-component material) is concerned, there has been no equipment and device that can complete the construction of the two-component material for a long time.

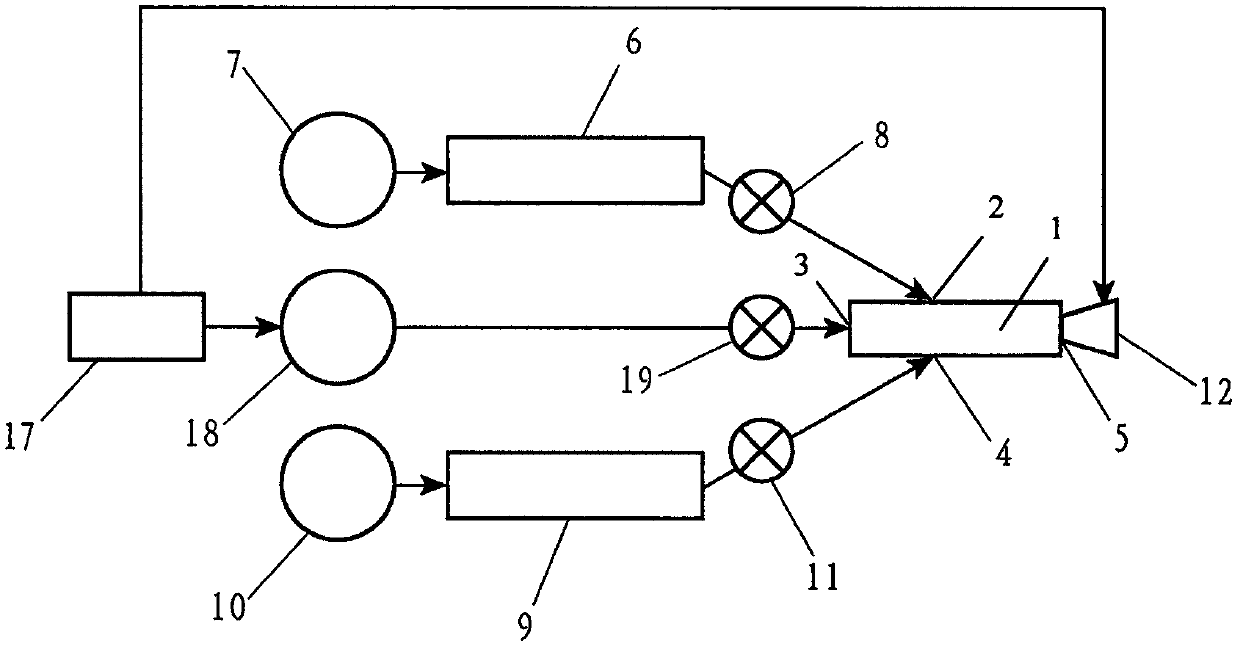

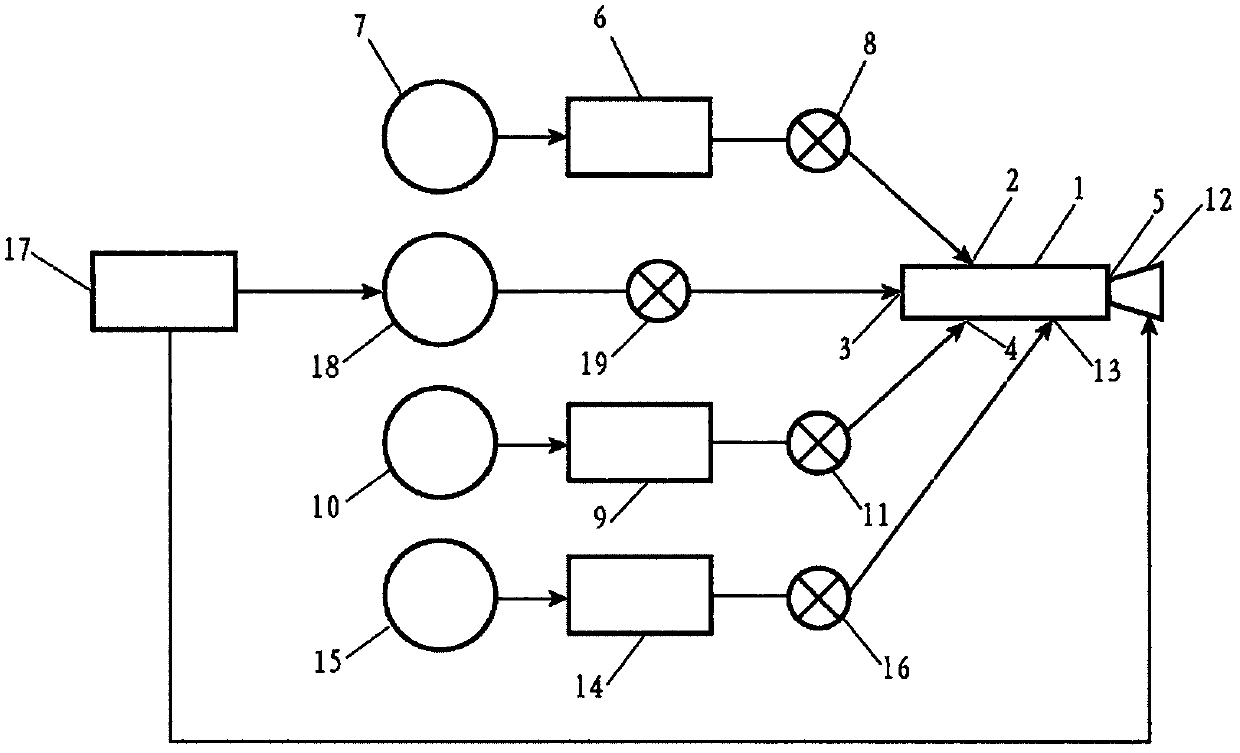

[0004] At present, the spraying equipment for

road construction of

methyl methacrylate high-strength polymers is two spraying machines, one spraying

machine is connected with A-component base material (such as Degu 660A marking paint currently sold in the market), and the other is spraying

Machine-

connected component B base material (such as Degu 660B marking paint currently sold in the market), one

sprayer sprays component A base material, and the other

sprayer immediately sprays component B base material (that is, sprays first Component A base material, and then spray component B base material on the

coating of component A base material), the problems of this kind of road spraying equipment are: 1. The construction is difficult (in the case that component A cannot be dried, it must Immediately spray component B again); 2. It is difficult to achieve complete equal coverage and superposition of the sprayed component A base material and component B base material; the coverage and superposition of the two components are not uniform, and the cured

coating will be uneven , Uneven curing means that there will be uneven

coating strength in future use, reflecting that some places on the

road surface are well maintained and others are easily damaged; 3. Part A base material and B component are prone to appear The base material does not overlap (because the base material of component A and the base material of component B are sprayed on the ground separately before and after, and the two components cannot be completely mixed evenly); Two-component crosslinking reaction, that is, the coating on the unsuperimposed part is always in the state of one-component base material, and the one-component base material coating does not have the basic functions of two-component pavement coatings such as strong adhesion and good

wear resistance; 4. Construction personnel need to stop regularly to add base material to the

sprayer; the existence of the above problems has led to the inability to achieve a continuous, high-efficiency, high-quality and rapid spraying of methyl

methacrylate (MMA) high-strength polymers in

road construction for a long time Operation;

[0005] The spraying equipment for

road construction of methyl

methacrylate high-strength

polymer can also be a spraying

machine. At this time, component A base material and B component base material (or multi-component base material) are directly added to the

storage material The problem of this kind of road spraying equipment is: the mixture of component A base material and component B base material must be sprayed immediately, otherwise, once the mixture in the stocker reacts, Spraying will become more and more difficult, because once the mixture enters the reaction state, the

viscosity will increase with time, the mixture will solidify in the spraying equipment, and eventually cause the spraying equipment to fail to work. At this time, the equipment must be cleaned and replaced. Only the re-mixed mixture can continue to work. The problem of frequent solidification or frequent replenishment of base materials has also caused road construction to be unable to achieve a continuous high-efficiency and high-quality two-component high-strength

polymer of methyl

methacrylate (MMA) for a long time. Fast spraying operation;

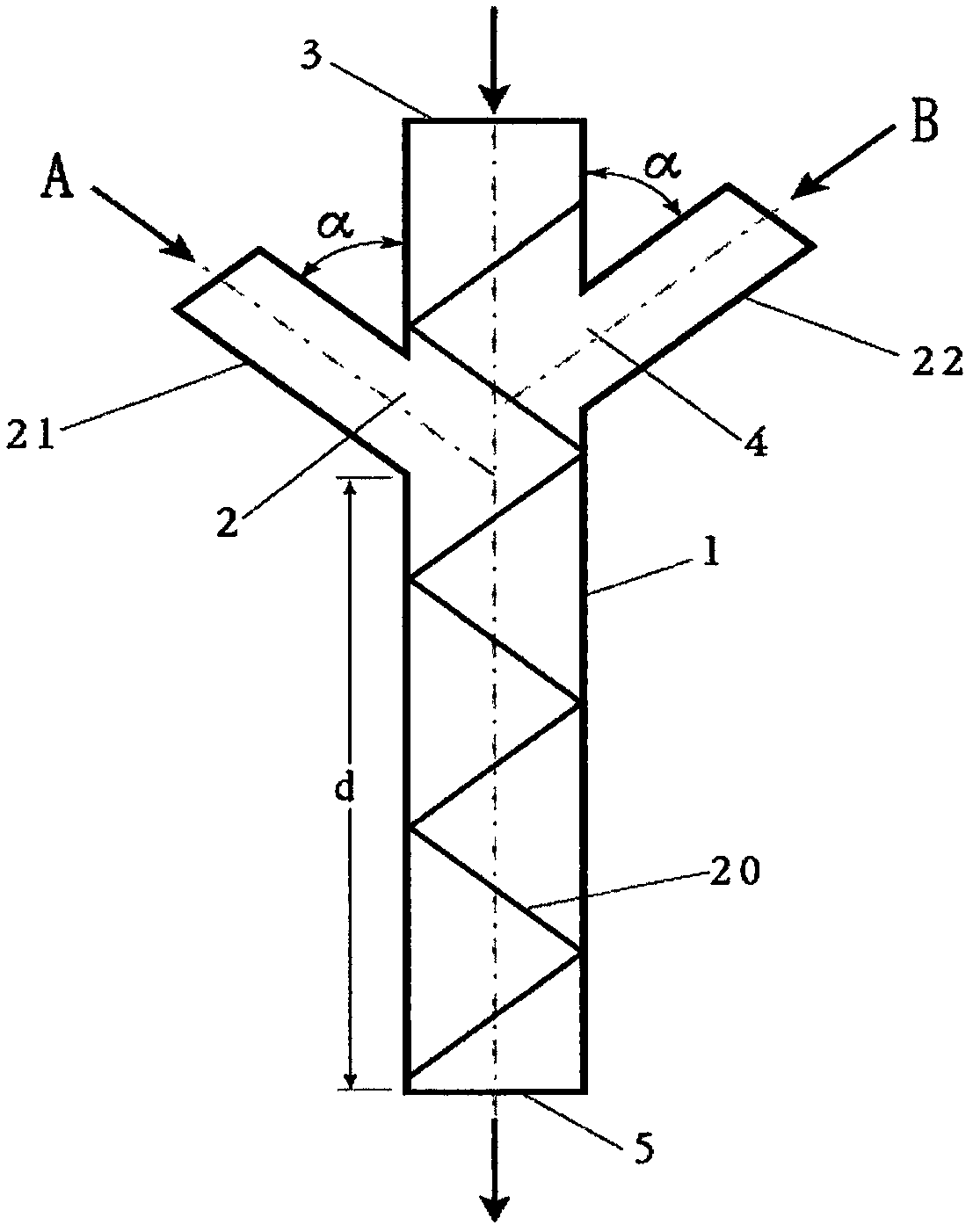

This kind of mixing method has strict requirements on the position setting of the two spray guns. If there is a slight misalignment, the full and proportional mixing of the base materials cannot be achieved, so that the sprayed line cannot meet the construction requirements; and in actual construction, due to

wind speed, Influenced by

airflow and other factors, the two-gun spray paint in the state of external spraying and external mixing cannot be fully and uniformly mixed, that is, the two-component base material mixing equipment of this structure cannot really realize the two-component base material in space or on the ground. The sufficient and uniform mixing of the above-mentioned first case will occur, and a continuous high-efficiency, high-quality and fast spraying operation of methyl methacrylate (MMA) high-strength polymers cannot be realized;

[0008] The other is

Chinese patent application CN103526683, which discloses a self-propelled two-component external mixing labeling line equipment, including two base material boxes, respectively put the A component base material and the B component base material into the corresponding base material. In the material box, open the

discharge port, the base materials of components A and B flow out at the same time, and flow to the stirring blade of the hopper, and the stirring blade rotates at a high speed, so that the base materials of components A and B are fully mixed before scraping or coating.

Spin coating; the problems of this kind of mixing equipment are: the pressure and

discharge volume of the two base material boxes need to be strictly controlled at any time, construction personnel are required to continuously supply materials to the two base material boxes, and the mixing volume and output of the materials in the hopper need to be monitored from time to time. Consumption, only when the two base material boxes are accurately discharged and the material in the hopper is evenly mixed, can the base material be fully and proportionally mixed, and the mixed material in the hopper should not be hoarded or used for a long time. If the material in the hopper If the material is stored too much or is not used up for a long time, the mixture will react and solidify in the hopper, and the problem of the second situation mentioned above will appear. In addition, frequent manual feeding and constant monitoring of complex ingredients and materials cannot be realized. A continuous high-efficiency high-quality rapid scraping or

spin coating of methyl methacrylate (MMA) high-strength

polymer, and it is even more impossible to realize a continuous high-efficiency high-quality rapid spraying operation of methyl methacrylate high-strength polymer;

[0009] Due to the two-component (or multi-component) material spraying or brushing after the

polymerization reaction with the construction subject, it can well protect the construction subject, greatly prolong the service life of the construction subject, and greatly improve the quality of the construction subject. The construction period is short, and it can be constructed in various harsh environments. The demand for construction with two-component (or multi-component) materials is growing stronger and stronger. However, because there is no construction equipment that can well complete the construction of two-component materials , forcing people to urgently need to find a kind of construction equipment, on the basis of fully considering the chemical characteristics of two-component (or multi-component) to solve the problem that two-component (or multi-component) materials have not been able to be high-quality, efficient and long-lasting for a long time. The technical problem of construction in time is to ensure that the two-component (or multi-component) fluid can not only ensure that the components can be fully mixed, but also ensure that no

chemical reaction has occurred between the components. During this extremely short reaction period, Quickly complete spraying or brushing operations to meet the construction needs of modern roads, bridges, grounds, roads and other two-component (or multi-component) materials, and truly realize continuous high-quality and high-efficiency two-component (or multi-component) materials at one time Fast construction work, solving long-standing problems with existing spraying installations

Login to View More

Login to View More  Login to View More

Login to View More