Low-pressure conveying spraying device

A spraying device and low-pressure technology, applied in roads, road repairs, roads, etc., can solve the problems of uneven coverage and superposition of two components, uneven coating strength, and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

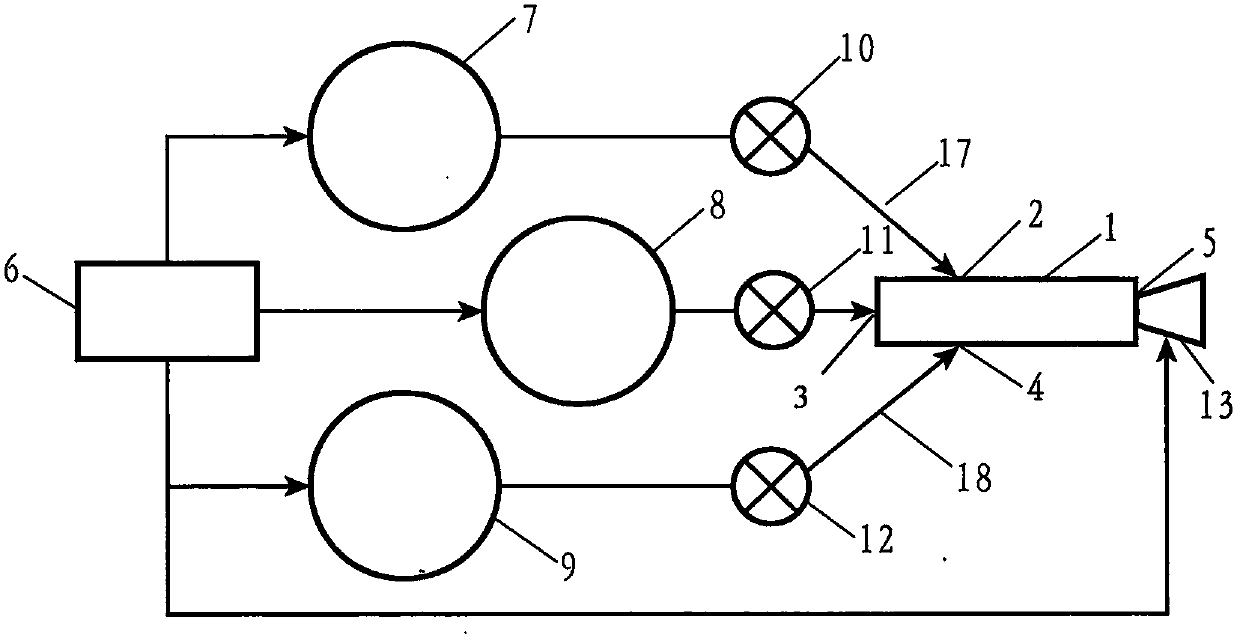

[0070] like figure 1 As shown, a low-pressure conveying spraying device has three sets of pressure conveying systems, including an air compressor 6, a first pressure vessel 7, a second pressure vessel 8, a third pressure vessel 9, a first valve 10, a second pressure vessel Second valve 11, third valve 12, static mixer, nozzle 13;

[0071] The air compressor 6 is respectively connected to one end of the first pressure vessel 7, the second pressure vessel 8, and the third pressure vessel 9 to supply air to form three sets of pressure conveying systems;

[0072] The volumes of the first pressure vessel 7 and the third pressure vessel 9 are between 0.01 and 15 cubic meters, specifically: 0.01 cubic meters, 0.02 cubic meters, 0.03 cubic meters, 0.04 cubic meters, 0.05 cubic meters, 0.06 cubic meters, 0.07 cubic meters, 0.08 cubic meters, 0.09 cubic meters, 0.1 cubic meters, 0.2 cubic meters, 0.3 cubic meters, 0.4 cubic meters, 0.5 cubic meters, 0.6 cubic meters, 0.7 cubic meters, ...

Embodiment 2

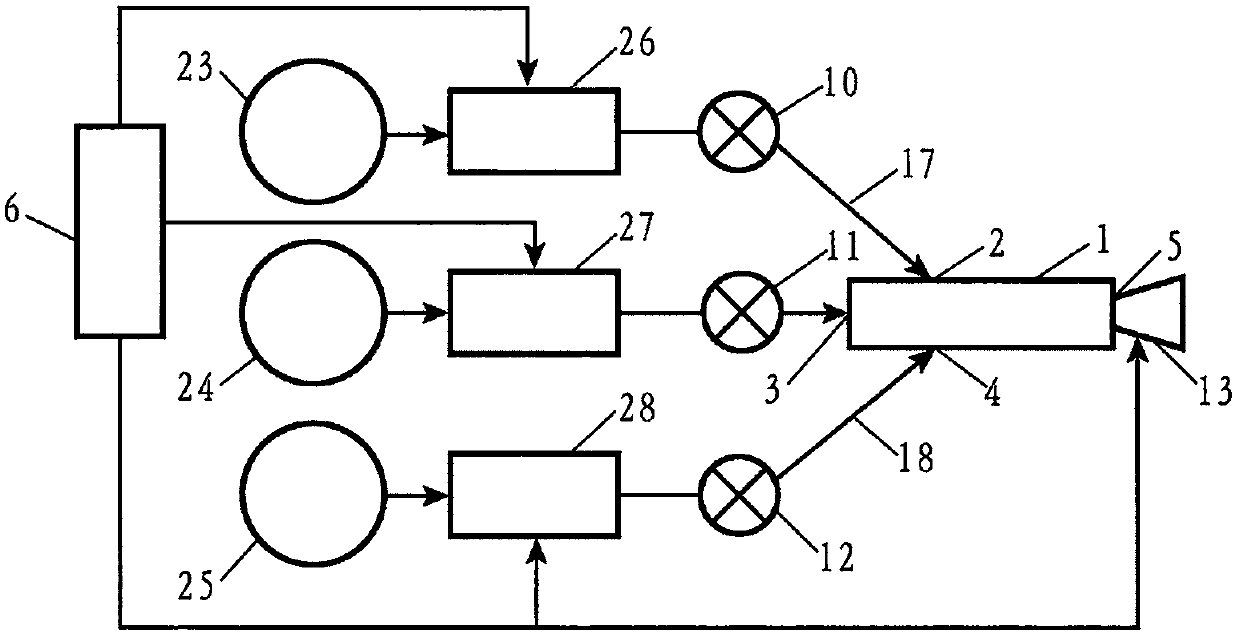

[0297] like image 3 As shown, a kind of low-pressure conveying spraying device, its structure is basically the same as that described in Embodiment 1, the only difference is that the first pressure vessel 7 is replaced by the first paint bucket 23, the first diaphragm pump module 26, and the second pressure vessel 8 is replaced by a cleaning bucket 24 and a cleaning diaphragm pump module 27, and the third pressure vessel 9 is replaced by a second paint bucket 25 and a second diaphragm pump module 28;

[0298] The diaphragm pump module can be composed of one diaphragm pump, or two diaphragm pumps connected in parallel, or three diaphragm pumps connected in parallel, or multiple diaphragm pumps connected in parallel;

[0299] Add paint to each paint bucket in real time, and at the same time equip a material supply vehicle to synchronize with the spraying operation vehicle to ensure the material supply of real-time feeding, so as to effectively realize continuous spraying operat...

Embodiment 3

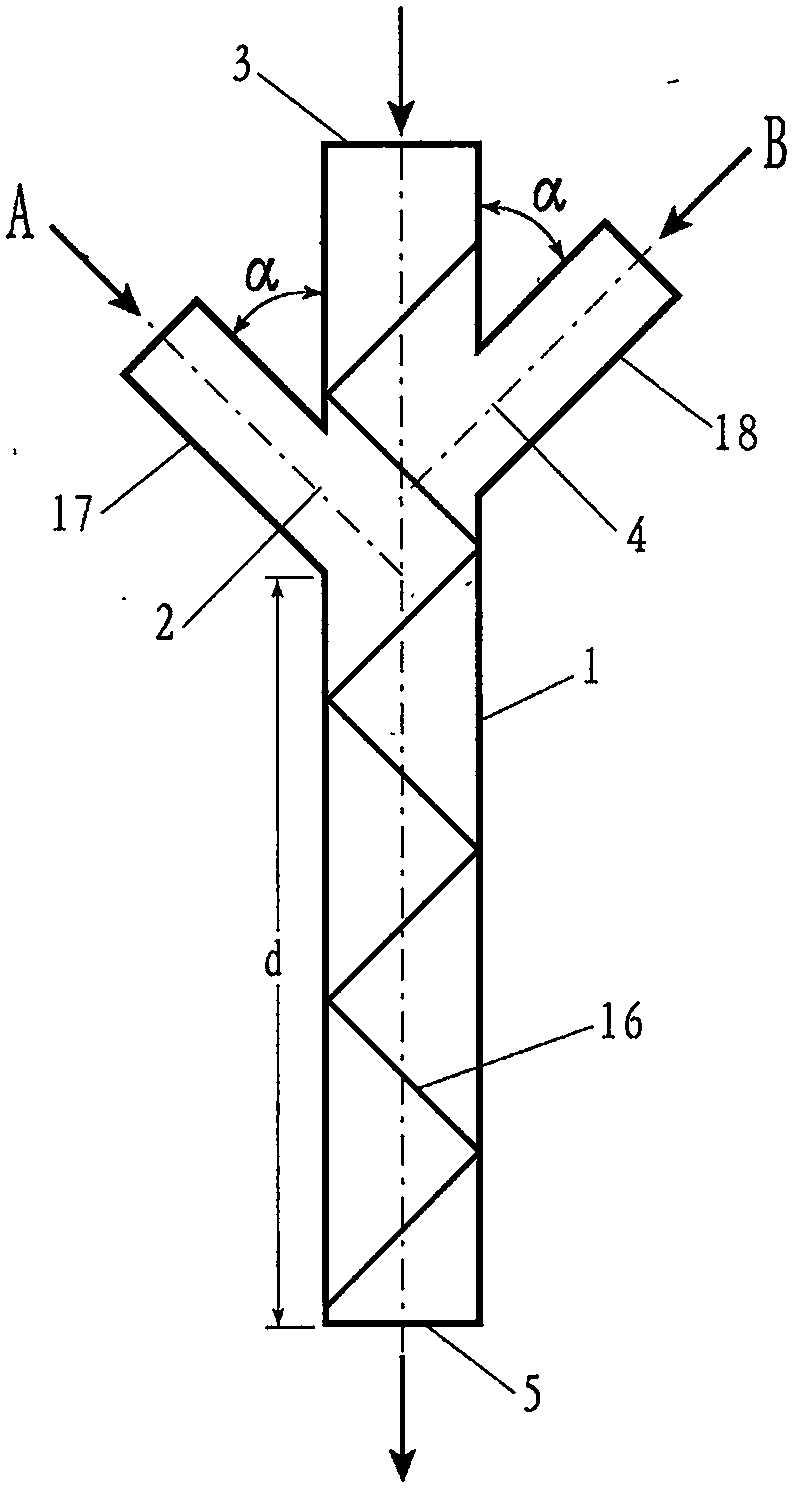

[0302] like Figure 8 Shown, a kind of low-pressure delivery spraying device, its structure is basically the same as that described in embodiment 1 or embodiment 2, the only difference is that there are three feed ports on the static mixer, as Image 6 As shown, each feeding branch pipe is relatively arranged on the mixing main pipeline 1 in the form of alternate leaves (the feeding branch pipes are arranged on the same plane of the mixing main pipeline 1), and the feeding ports of each feeding branch pipe correspond to the spiral Different positions of the deflectors, the low-pressure conveying and spraying device also includes a fourth pressure vessel 14 and a fourth valve 15;

[0303] The inner diameter of the third component (component C) feed branch pipe 22 (or other feed branch pipes) is 0.5 cm to 100 cm, specifically 0.5 cm, or 1 cm, or 2 cm, or 3 cm, or 4 cm , or 5 cm, or 6 cm, or 7 cm, or 8 cm, or 9 cm, or 10 cm, or 11 cm, or 12 cm, or 13 cm, or 14 cm, or 15 cm, or 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com