Method for extending the service life of aged scr catalyst beds in emission systems from stationary sources of nox

A kind of SCR catalyst and catalyst technology, which is applied in the direction of exhaust equipment, exhaust treatment, machine/engine, etc., and can solve the problems of corrosion of downstream components and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

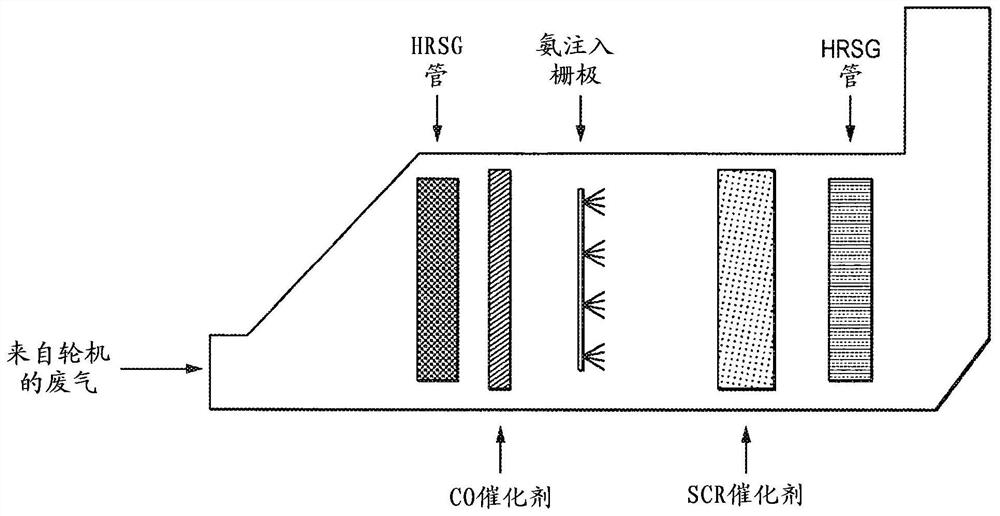

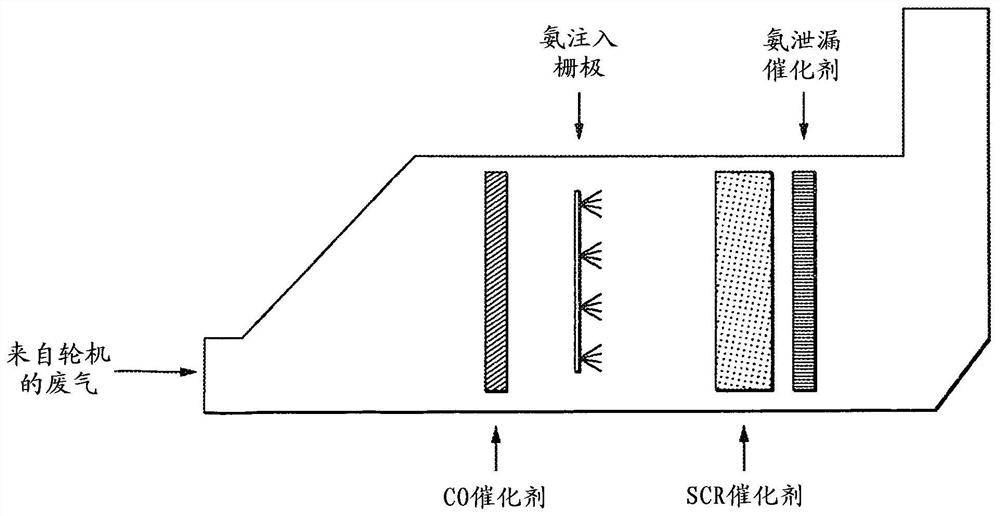

Image

Examples

Embodiment Construction

[0022] In practice, the relatively small volume of the improved honeycomb substrate monolith or panel substrate containing the catalyst for the conversion of ammonia in exhaust gases that also contain oxygen to nitrogen and water is only sufficient to enable the improved catalyst to be used in conjunction with SCR The replacement cost of the catalyst is one of the factors compared to manufacturing at a lower cost. Improved catalyst cost over 20% less than SCR catalyst replacement cost

[0023] An ammonia slip catalyst is designed to selectively promote the following overall reactions:

[0024] 4NH 3 +3O 2 →2N 2 +6H 2 O (4)

[0025] As described in more detail below, U.S. Patent Application Publications 2007 / 0110643A1, 2016 / 0245139A1, and 2016 / 0256823A1 propose the use of ammonia slip catalysts (also known as ammonia oxidation ("AMOX") catalysts) as SCR catalysts in exhaust systems of gas turbine engines. downstream of or in combination with it.

[0026] However, power p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com