Cotton reaction type phosphorus-nitrogen-sulfur synergistic flame retardant preparation method

A synergistic flame retardant, reactive technology, applied in flame retardant fibers, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

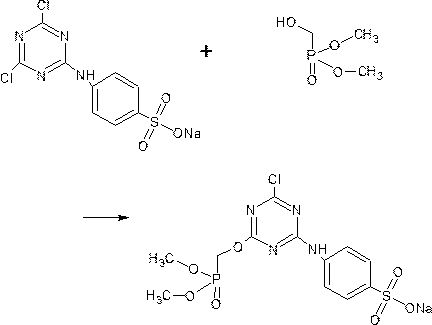

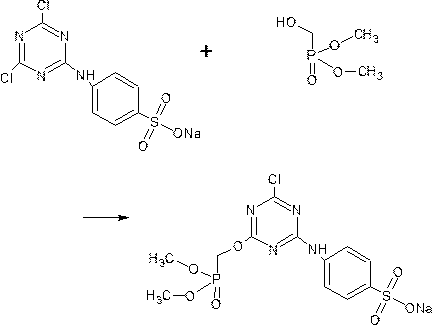

Image

Examples

Embodiment 1

[0011] (1) Add 9.22g (0.05mol) of cyanuric chloride to a three-necked flask, add an appropriate amount of acetone as a solvent, dissolve 11.56g (0.05mol) of p-aminobenzenesulfonic acid sodium salt in an appropriate amount of distilled water, and use an iron stand to The three-necked flask containing the cyanuric chloride solution was fixed in an ice-water bath, and the sodium p-aminobenzenesulfonate solution was added dropwise into the three-necked flask, kept at 0°C and continuously stirred for reaction, and the pH was adjusted to 5-5 with 20% sodium carbonate aqueous solution. 6. The reaction was carried out for 1 hour, and the main product was dichloro-s-triazine-based sodium p-aminobenzenesulfonate (product A).

[0012] (2) Add 17.12g of product A into the three-necked flask, use distilled water as the solvent, stir evenly, and fix the three-necked flask in the warm water bath of the heat-collecting magnetic stirrer with an iron stand, set the temperature at 55°C, and then ...

Embodiment 2

[0019] (1) Add 5.53g (0.03mol) of cyanuric chloride to a three-necked flask, add an appropriate amount of acetone as a solvent, dissolve 6.94g (0.03mol) of sodium p-aminobenzenesulfonic acid in an appropriate amount of distilled water, and use an iron stand to The three-necked flask containing the cyanuric chloride solution was fixed in an ice-water bath, and the sodium p-aminobenzenesulfonate solution was added dropwise into the three-necked flask, kept at 0°C and continuously stirred for reaction, and the pH was adjusted to 5-5 with 20% sodium carbonate aqueous solution. 6. The reaction was carried out for 1 hour, and the main product was dichloro-s-triazine-based sodium p-aminobenzenesulfonate (product A).

[0020] (2) Add 10.27g of product A into the three-necked flask, use distilled water as the solvent, stir evenly, and fix the three-necked flask in the warm water bath of the heat-collecting magnetic stirrer with an iron stand, set the temperature at 55°C, and then put 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com