Low-temperature-resistant self-healing hydrogel preparation method and application

A hydrogel, self-healing technology, applied in applications, strain gauges, sensors, etc., can solve the problems of limiting the application prospects of hydrogels, short storage time, and easy loss of water, so as to improve toughness and mechanical properties , enhanced intermolecular force, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

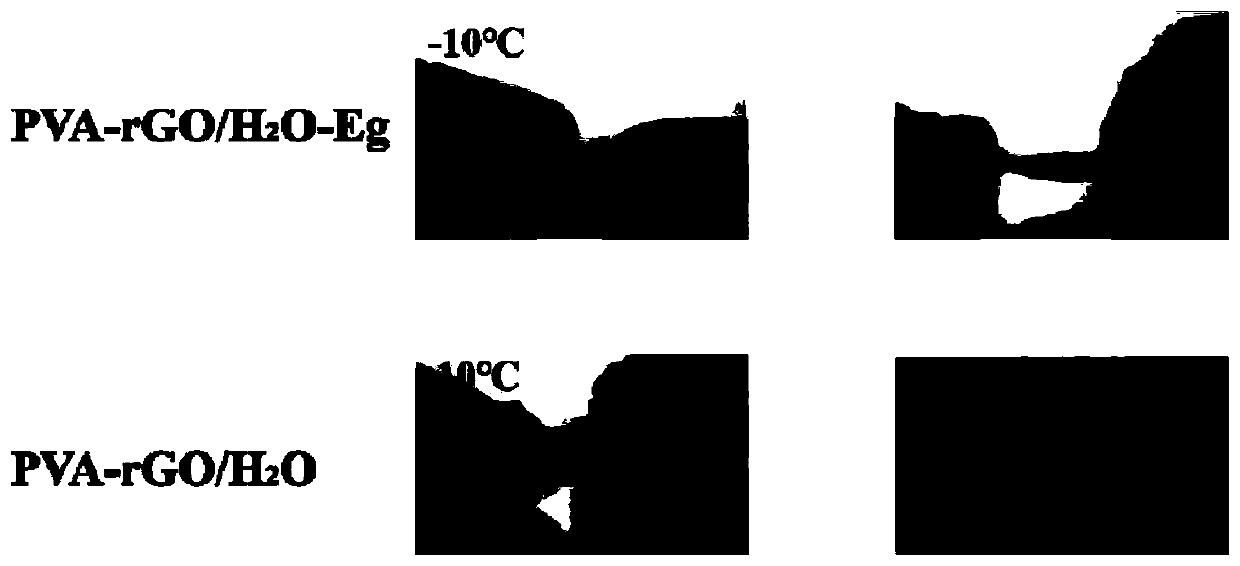

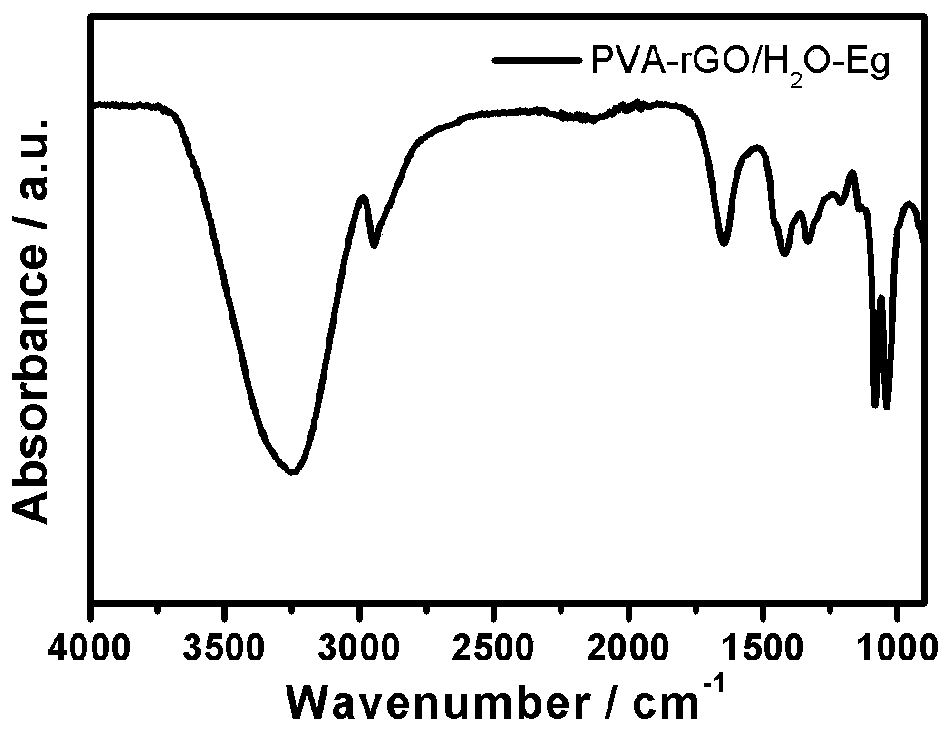

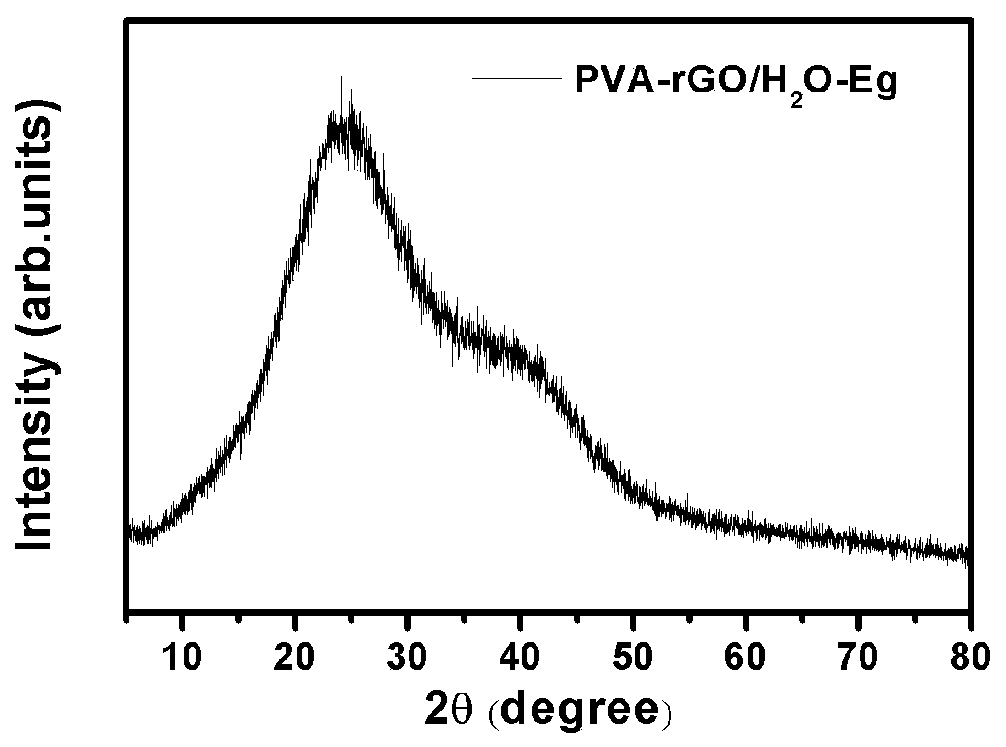

[0040] (1) 10 grams, 15 grams and 20 grams of polyvinyl alcohol (molecular weight is 95000, and the degree of hydrolysis is 95%) are added to 90 grams, 85 grams and 80 grams of deionized water and ethyl alcohol dispersed with redox graphene respectively. In a diol solvent (the solvent ratio of deionized water to ethylene glycol is 2:1, and the concentration of redox graphene is 0.5mg / mL), stir at 90°C for 3 hours until the PVA is completely dissolved to form a uniform mass PVA mixed solutions with concentrations of 10wt%, 15wt% and 20wt%.

[0041] (2) Dissolve 1.5 grams of borax in a mixed solvent of 98.5 mL of deionized water and ethylene glycol dispersed with redox graphene (the solvent ratio of deionized water and ethylene glycol is 2:1, and the concentration of redox graphene 0.5 mg / mL), heated and stirred at 60°C for 30 minutes to dissolve completely, and prepared a 1.5 mg / mL borax mixed solution.

[0042] (3) Take PVA mixed solutions of different mass concentrations in ...

Embodiment 2

[0044] (1) get 20 grams of polyvinyl alcohol (molecular weight is 95000, degree of hydrolysis is 95%) joins in the mixed solution of deionized water and ethylene glycol that 80 grams are dispersed with redox graphene (deionized water and ethylene glycol The ratio of alcohol is 2:1, the redox graphene concentration is 0.5mg / mL), heated at 90°C and stirred for 3 hours, until the PVA is completely dissolved to form a uniform 20wt% PVA mixed solution.

[0045] (2) 0.5 g, 1.0 g, 1.5 g, 2.0 g, and 2.5 g of borax were dissolved in 99.5 mL, 99.0 mL, 98.5 mL, 98.0 mL, and 97.5 mL of deionized water and ethylene dioxide dispersed with redox graphene, respectively. In a mixed solvent of alcohol (the ratio of deionized water to ethylene glycol is 2:1, and the redox graphene concentration is 0.5mg / mL), heat and stir at 60°C for 30 minutes to dissolve completely, and prepare 0.5mg / mL, 1.0 mg / mL, 1.5mg / mL, 2.0mg / mL and 2.5mg / mL borax mixed solutions.

[0046] (3) Take the PVA mixed solution...

Embodiment 3

[0048] (1) Get 20 grams of polyvinyl alcohol (molecular weight is 95000, degree of hydrolysis is 95%) and add 80 grams of redox graphene dispersed in deionized water and ethylene glycol mixed solution (deionized water and ethylene glycol The ratios are 3:1, 2:1, 1:1 and 1:2 respectively, and the redox graphene concentration is 0.5mg / mL), heated at 90°C and stirred for 3 hours, until the PVA is completely dissolved to form a uniform different Solvent ratio of PVA mixed solution.

[0049] (2) Dissolve 1.5 grams of borax in a mixed solution of 98.5 mL of redox graphene-dispersed deionized water and ethylene glycol (the solvent ratios of deionized water and ethylene glycol are 3:1, 2:1, respectively. , 1:1 and 1:2, the redox graphene concentration is 0.5mg / mL), heated and stirred at 60°C for 30 minutes to dissolve completely, and prepared borax mixed solutions with different solvent ratios.

[0050] (3) Take PVA mixed solutions with different solvent ratios in a beaker, add the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com