Method for separating and purifying myxobolus honghuensis polar capsule

A technology for separation, purification and iodine algae, which is applied in the biological field, can solve the problems of lack of technical specifications, high cost, complicated operation and the like, and achieves the effects of convenient operation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

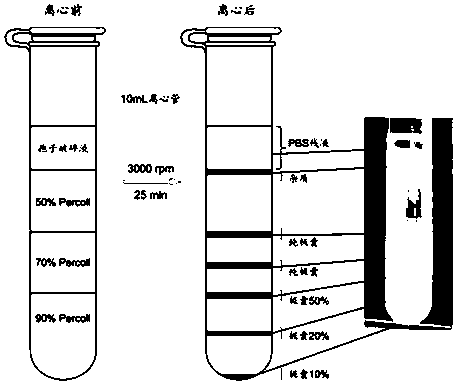

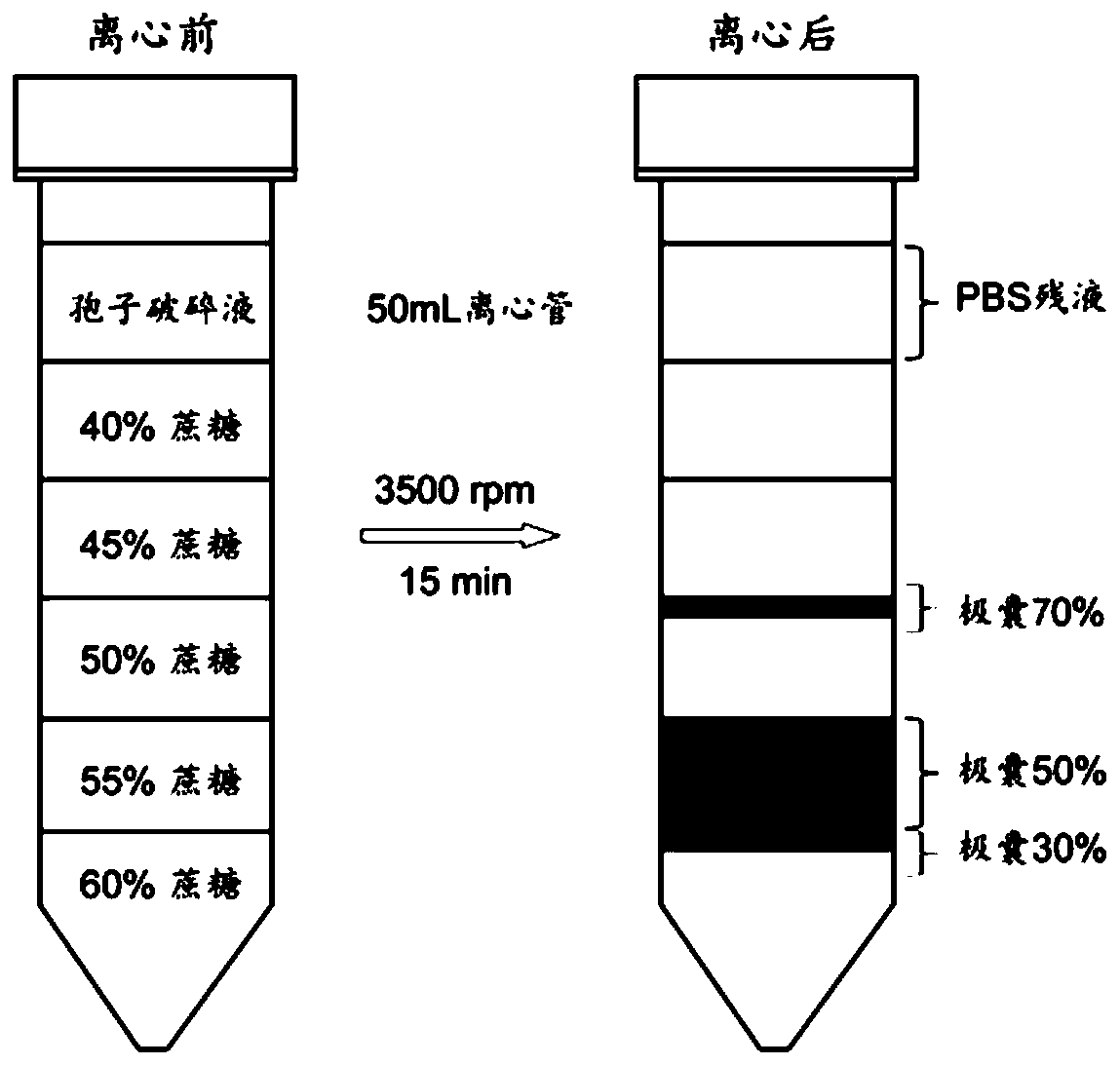

[0023] The present invention is a separation method based on gradient centrifugation, and its key elements are centrifugal medium (sucrose, Percoll, etc.) and gradient composition. In order to determine the optimal method for the separation and purification of Honghu iodine polar capsules, a series of explorations and optimizations were carried out on the key elements of the gradient centrifugation steps:

[0024] Scheme 1 used sucrose with low cost as the centrifugation medium, and carried out the first exploration of polar capsule separation. The steps are as follows:

[0025] A. Take 5 mL of Honghu iodine spore fragmentation solution and add it to the bottom of a 50 mL centrifuge tube;

[0026] B. Through the syringe, inject the sucrose solutions with mass percentages of 40%, 45%, 50%, 55%, and 60% into the centrifuge tube in sequence, each layer is 8mL;

[0027] C, 3500rpm speed, centrifugal 15min;

[0028] Results: After centrifugation, the ratio of polar capsules to sh...

Embodiment 2

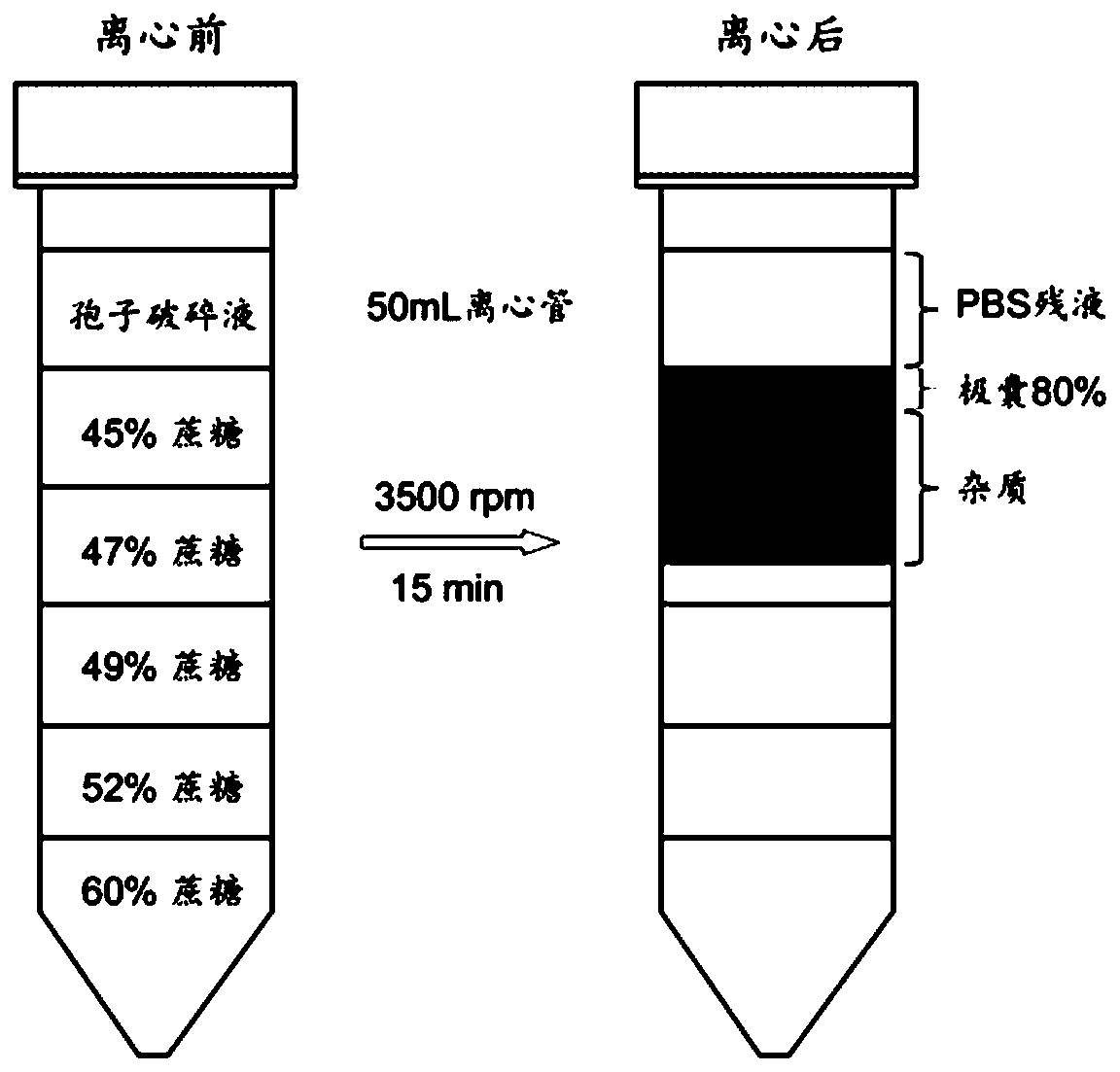

[0043] The separation and purification method of Honghu iodine polar capsules includes tissue sample homogenization, spore purification, ultrasonic crushing, Percoll gradient centrifugation, polar capsule recovery, secondary purification, resuspension and cleaning of recovered liquid, and the specific steps are as follows:

[0044] A. Tissue sample homogenization: cut out the crucian crucian throat that was found to contain Honghu iodine cysts by microscopic examination, put it into a hand-held homogenizer, and then add 0.1M PBS buffer to grind thoroughly until there is no obvious tissue in the homogenizer. organization block;

[0045]B. Purification of spores: filter the homogenate with double layers of medical gauze, collect the filtrate; centrifuge at 2500rpm for 15min, wash twice with 0.1M PBS buffer, resuspend the spores to 8mL with PBS, and add to the bottom of a 50mL centrifuge tube ; The sucrose solutions with mass percentages of 30%, 40%, 50%, and 60% were injected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com