Method for controlling form of free cutting steel sulfide by additionally adding oxide

A free-cutting steel and oxide technology, applied in the field of metallurgy, can solve problems such as uncontrollable sulfide morphology, and achieve the effects of easy sulfide recombination, saving production costs, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

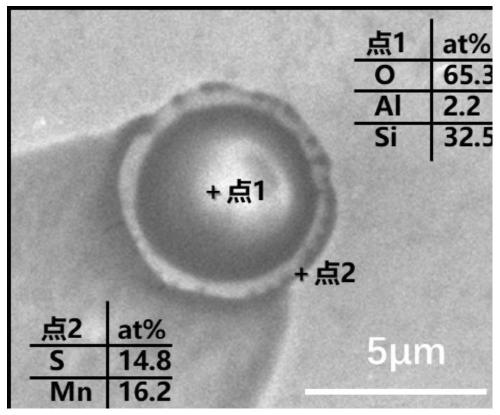

[0028] 1. Put xAl2 o 3 ·SiO2 2 (x=4~10%) The powder is cleaned with alcohol and dried in a dryer; the oxide size after ball milling is measured by a BT-2001 (wet method) laser particle size distribution analyzer, and xAl of 2 o 3 ·SiO2 2 (x=4~10%) powder; Selection purity is that 99% particle is 200 mesh iron powders, and carbon-sulfur analyzer analyzes its sulfur content and is 90ppm; Pure iron powder, manganese powder, xAl 2 o 3 ·SiO2 2 (x=4~10%) powder, Fe 2 S powder is mixed according to a certain ratio, and the mixture is pressed into a block by a hydraulic press. In the block mixture, the quality of sulfur element is controlled at 0.2% to 0.4%, and the content of oxygen element is controlled at 100 to 150ppm. The mass of sulfur element and oxygen element The ratio is 1:0.04~0.08, and the melting is carried out in a MoSi2 high temperature vertical tube furnace.

[0029] 2. The sample obtained by smelting, after inlaying, the surface of the sample is treated by conve...

Embodiment 2

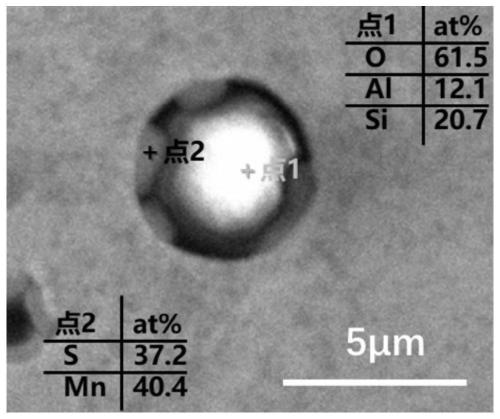

[0031] 1. Put xAl 2 o 3 ·SiO2 2 (x=30~40%) The powder is washed with alcohol and dried in a dryer; the oxide size after ball milling is measured by a BT-2001 (wet method) laser particle size distribution analyzer, and xAl of 2 o 3 ·SiO2 2 (x=30~40%) powder; Selection purity is that 99% particle is 200 mesh iron powders, and carbon-sulfur analyzer analyzes its sulfur content and is 90ppm; Pure iron powder, manganese powder, xAl 2 o 3 ·SiO2 2 (x=30~40%) powder, Fe 2 S powder is mixed according to a certain ratio, and the mixture is pressed into a block by a hydraulic press. In the block mixture, the quality of sulfur element is controlled at 0.2% to 0.4%, and the content of oxygen element is controlled at 100 to 150ppm. The mass of sulfur element and oxygen element The ratio is 1:0.04~0.08, and the melting is carried out in a MoSi2 high temperature vertical tube furnace.

[0032] 2. The samples obtained by smelting are surface treated by conventional mechanical grinding a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com