An annular coaxial powder feeding device for ultra-high-speed laser cladding

A technology of coaxial powder feeding and laser cladding, which is applied in the coating process and coating of metal materials, can solve the problems of difficult production, low powder concentration, and low powder concentration, so as to improve the uniformity of space distribution and coating The effect of small layer surface roughness and small powder focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

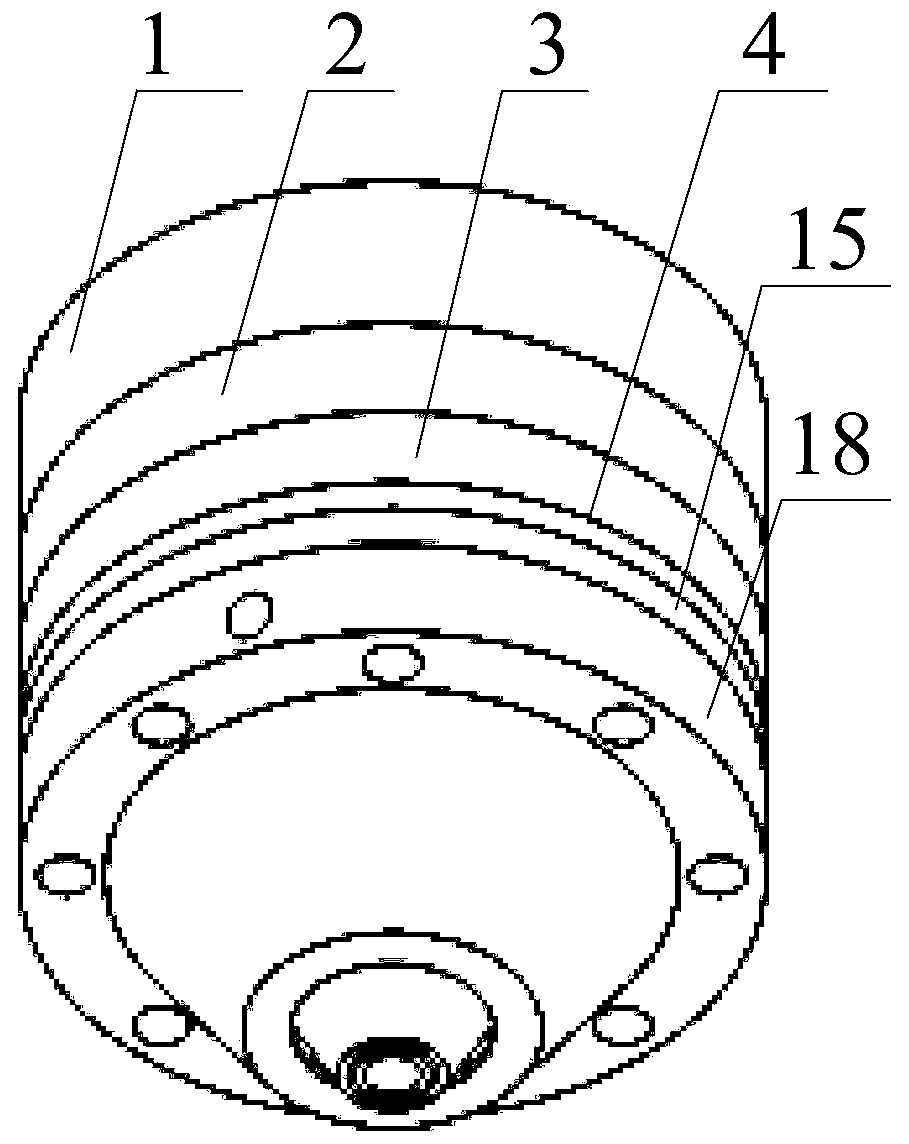

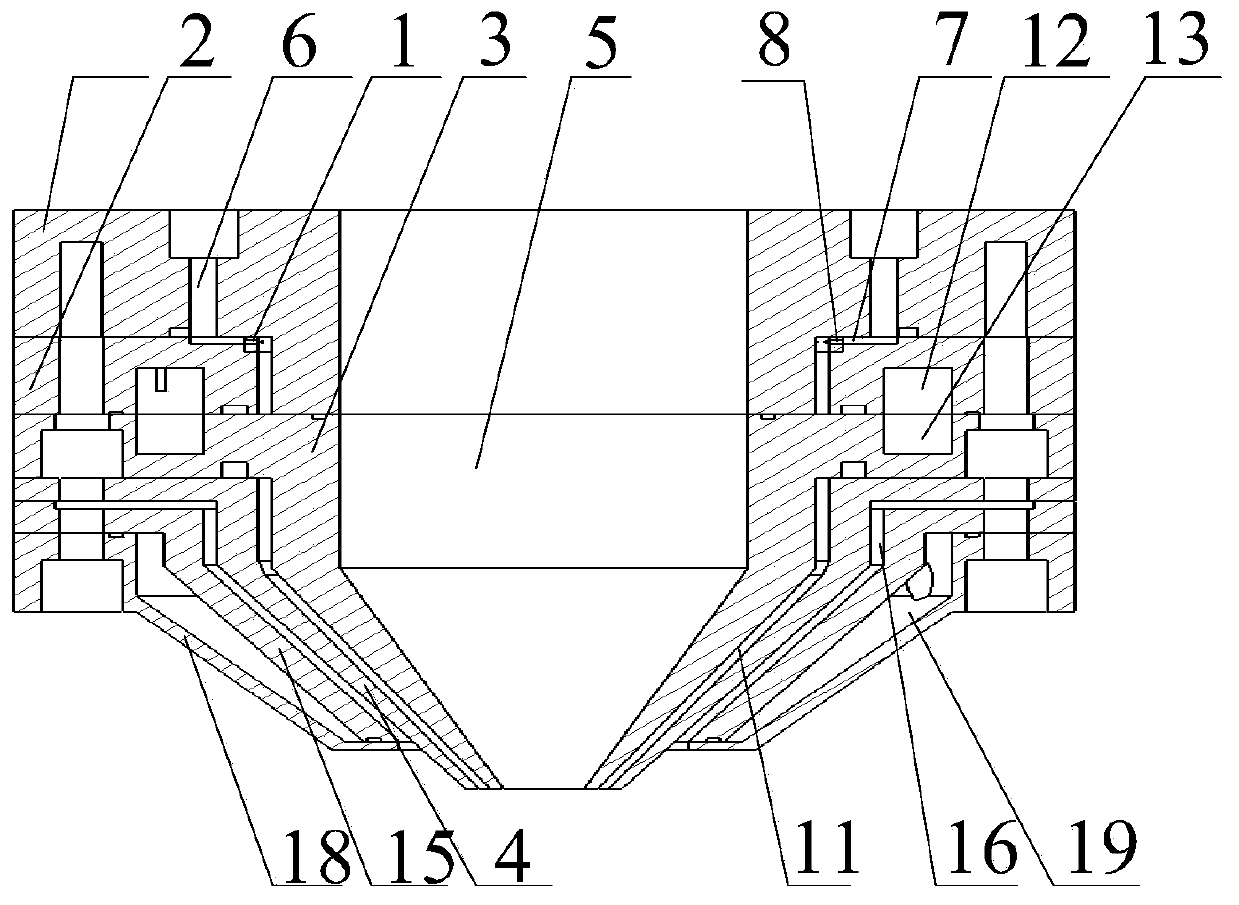

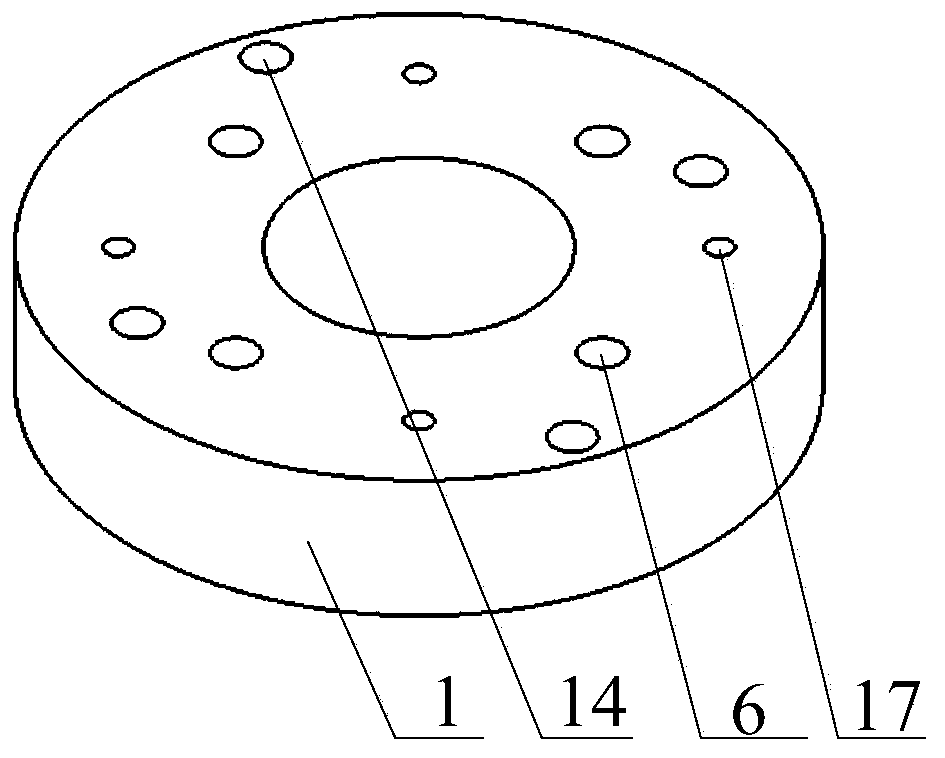

[0044] Reference figure 1 , Shows a schematic diagram of the three-dimensional structure of an annular coaxial powder feeding device for ultra-high-speed laser cladding according to an embodiment of the present invention; figure 2 , Shows a schematic cross-sectional structure diagram of an annular coaxial powder feeding device for ultra-high-speed laser cladding according to an embodiment of the present invention. The annular coaxial powder feeding device of the embodiment of the present invention includes:

[0045] The laser optical system, and the top part 1, the middle part 2, the first cone part 3 and the second cone part 4 connected sequentially from top to bottom, the top part 1, the middle part 2, the first The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com