Protective agent for water circulation system, and preparation method thereof

A circulatory system, system protection technology, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as corrosion, achieve long life, excellent high temperature resistance, good The effect of reserve alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A water circulation system protection agent, the water circulation system protection agent comprises the following raw material components:

[0051] Gluconic acid 8g, HEDP synthesis agent 15g, polyaspartic acid 8g, adipic acid 3g, sodium octanoate 8g, triethanolamine 10g, deionized water 25g and monoethanolamine 5g.

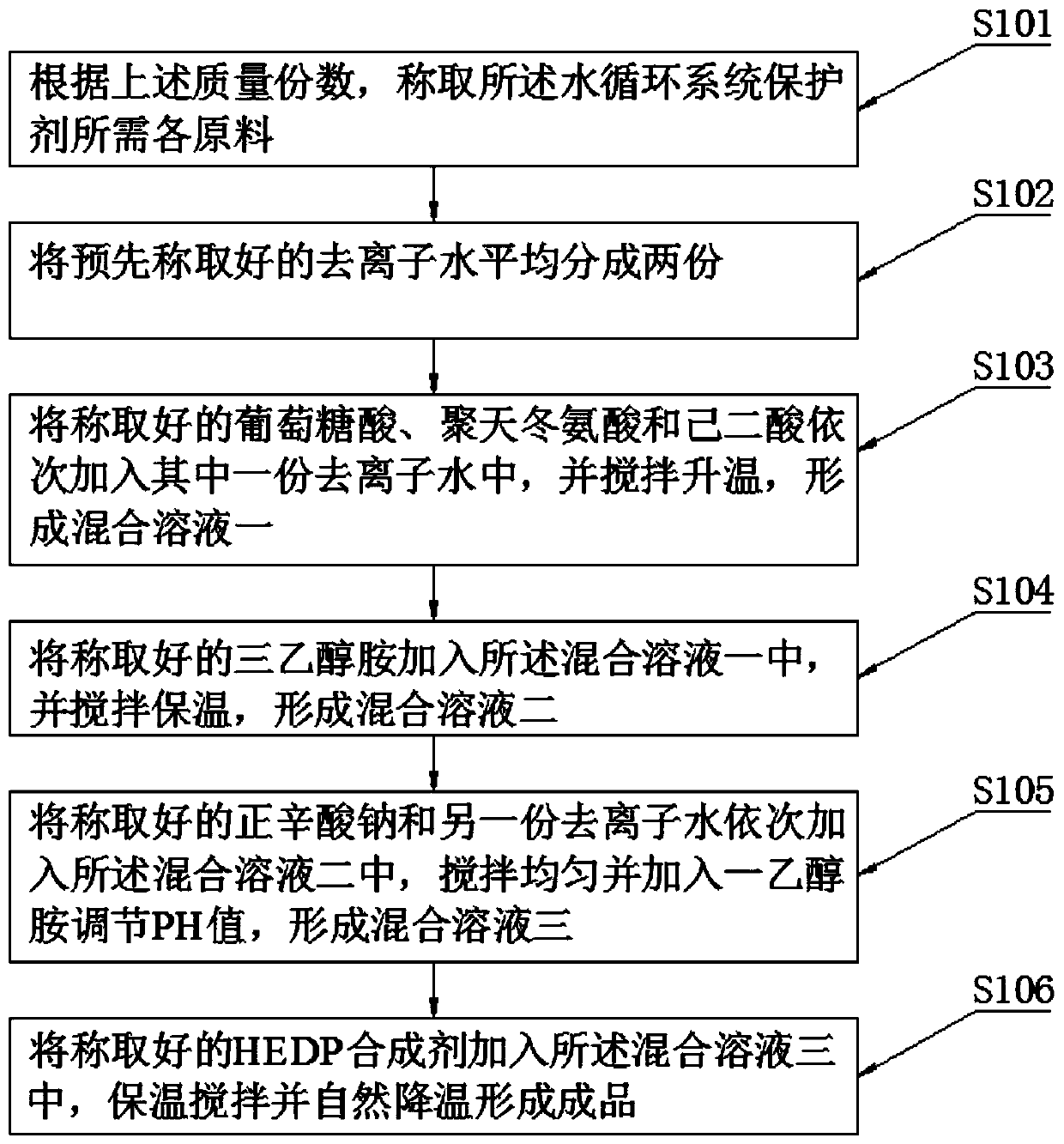

[0052] The preparation of this water circulation system protection agent comprises the following steps:

[0053] According to the above-mentioned mass parts, each raw material required for the water circulation system protection agent is weighed;

[0054]Divide the pre-weighed deionized water into two parts;

[0055] Add 8 g of gluconic acid, 8 g of polyaspartic acid and 3 g of adipic acid into one portion of deionized water 12.5 g in sequence, and stir to raise the temperature to form mixed solution 1;

[0056] Add 10 g of the weighed triethanolamine into the mixed solution 1, and stir and keep warm to form the mixed solution 2;

[0057] Add 8 g of sod...

Embodiment 2

[0060] A water circulation system protection agent, the water circulation system protection agent comprises the following raw material components:

[0061] Gluconic acid 10g, HEDP synthesis agent 20g, polyaspartic acid 10g, adipic acid 5g, sodium octanoate 10g, triethanolamine 15g, deionized water 30g and monoethanolamine 6g.

[0062] The preparation of this water circulation system protection agent comprises the following steps:

[0063] According to the above-mentioned mass parts, each raw material required for the water circulation system protection agent is weighed;

[0064] Divide the pre-weighed deionized water into two parts;

[0065] Add 10 g of gluconic acid, 10 g of polyaspartic acid and 5 g of adipic acid into one portion of 15 g of deionized water in sequence, and stir to raise the temperature to form a mixed solution 1;

[0066] Add 15 g of the weighed triethanolamine into the mixed solution 1, and stir and keep warm to form the mixed solution 2;

[0067] Add 1...

Embodiment 3

[0070] A water circulation system protection agent, the water circulation system protection agent comprises the following raw material components:

[0071] Gluconic acid 12g, HEDP synthesis agent 25g, polyaspartic acid 12g, adipic acid 7g, sodium octanoate 12g, triethanolamine 20g, deionized water 35g and monoethanolamine 7g.

[0072] The preparation of this water circulation system protection agent comprises the following steps:

[0073] According to the above-mentioned mass parts, each raw material required for the water circulation system protection agent is weighed;

[0074] Divide the pre-weighed deionized water into two parts;

[0075] Add 12 g of gluconic acid, 12 g of polyaspartic acid and 7 g of adipic acid into one portion of deionized water 17.5 g in sequence, and stir to raise the temperature to form a mixed solution 1;

[0076] Add 20 g of the weighed triethanolamine into the mixed solution 1, and stir and keep warm to form the mixed solution 2;

[0077] Add 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com