Chelated copolymer gel layer coated nickel-cobalt-aluminum ternary positive electrode material as well as preparation method and application thereof

A cathode material and copolymer technology, which is applied in the field of chelating copolymer gel layer-coated nickel-cobalt-aluminum ternary cathode materials and its preparation, can solve the problems of interface impedance increase, battery performance loss, poor connectivity, etc., and achieve optimization High contact resistance, high capacity retention rate, and the effect of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A chelating copolymer gel layer coated nickel-cobalt-aluminum ternary positive electrode material, made of LiNi 0.8 co 0.15 al 0.05 o 2 Active particles, chelating copolymer PVDF-GMA-IDA and bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI) were prepared.

[0038] A kind of preparation method of the chelate copolymer gel layer coated nickel-cobalt-aluminum ternary positive electrode material of the present embodiment, comprises the following steps

[0039] S1. Disperse the chelating copolymer and the ionic liquid in N-methylpyrrolidone (NMP) solvent, and stir evenly to obtain a polymer solution;

[0040] Take 0.003g chelating copolymer PVDF-GMA-IDA and 0.006g ionic liquid 1-ethyl-3-methylimidazolium trifluoromethanesulfonate (EMITFSI) and disperse in 8g NMP and magnetically stir for 0.5 hours to form a uniform polymerization substance solution.

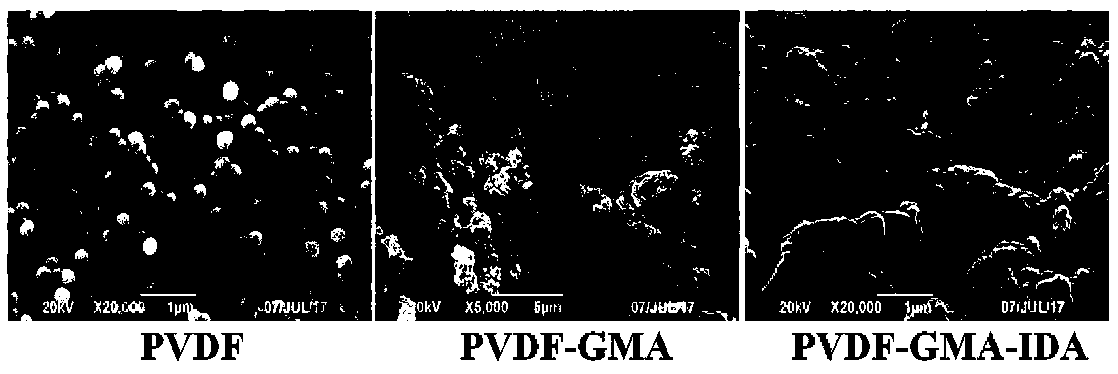

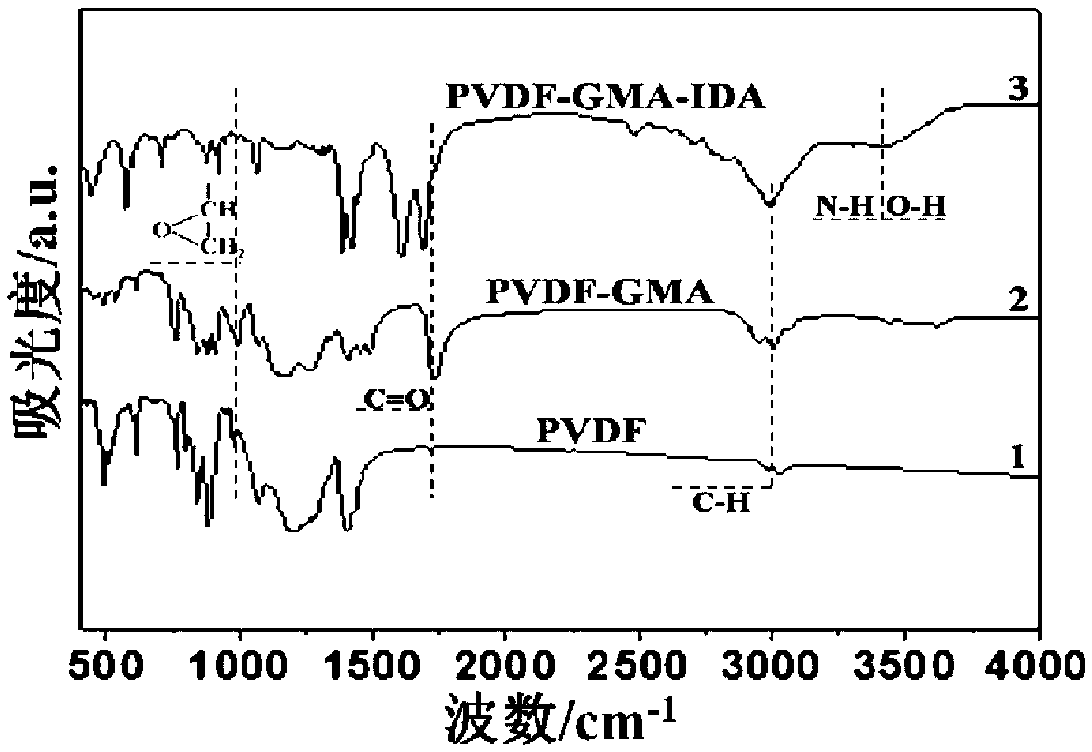

[0041] The chelate copolymer in this example is obtained from polyvinylidene fluoride (PVDF), glyceryl me...

Embodiment 2

[0049] The chelate copolymer gel layer of the present embodiment coats nickel-cobalt-aluminum ternary positive electrode material, is made of LiNi 0.8 co 0.15 al 0.05 o 2 Active particles, chelating copolymer PVDF-GMA-IDA and bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI) were prepared.

[0050] The preparation method of the chelate copolymer gel layer coated nickel-cobalt-aluminum ternary positive electrode material of the present embodiment comprises the following steps:

[0051] S1. Take 0.0408g of chelating copolymer PVDF-GMA-IDA prepared in Example 1 and 0.0816g of ionic liquid 1-ethyl-3-methylimidazolium trifluoromethanesulfonate (EMITFSI) dispersed in 8g of NMP and Magnetic stirring was carried out for 0.5 h to form a homogeneous polymer solution.

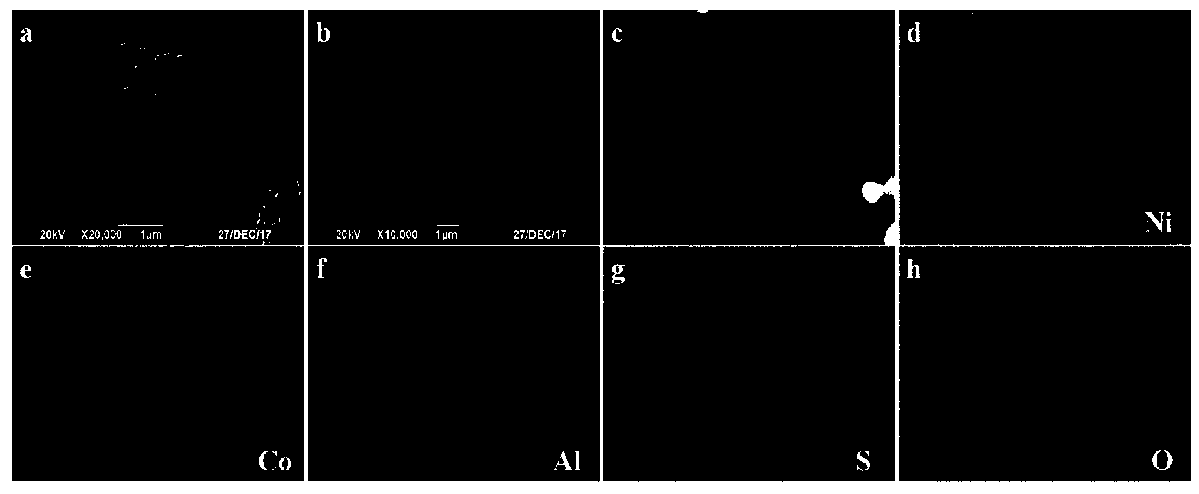

[0052] S2, 2g LiNi 0.8 co 0.15 al 0.05 o 2 The powder was immersed in the polymer solution and stirred at 60 °C for 4 hours to induce the reaction between the gel polymer PVDF-GMA-IDA and the NCA ac...

Embodiment 3

[0054] The chelate copolymer gel layer of the present embodiment coats nickel-cobalt-aluminum ternary positive electrode material, is made of LiNi 0.8 co 0.15 al 0.05 o 2 Active particles, chelating copolymer PVDF-GMA-IDA and bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI) were prepared.

[0055] The preparation method of the chelate copolymer gel layer coated nickel-cobalt-aluminum ternary positive electrode material of the present embodiment comprises the following steps:

[0056] S1, 0.0619g chelating copolymer PVDF-GMA-IDA and 0.1237g ionic liquid 1-ethyl-3-methylimidazolium trifluoromethanesulfonate (EMITFSI) prepared in Example 1 were dispersed in 8g NMP and Magnetic stirring was carried out for 0.5 h to form a homogeneous polymer solution.

[0057] S2, 2g LiNi 0.8 co 0.15 al 0.05 o 2 The powder was immersed in the polymer solution and stirred at 60 °C for 4 hours to induce the reaction between the gel polymer PVDF-GMA-IDA and the NCA particles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com