A method for suppressing cracking damage in grinding of hard and brittle materials by surface toughening

A grinding technology for hard and brittle materials, which is applied in the field of surface toughening to suppress cracking damage in grinding and processing of hard and brittle materials. It can solve the problems of diamond grinding wheel temperature rise, operation difficulty and high cost, and heat sensitivity of hard and brittle materials. , to achieve the effect of reducing processing cost, improving processing quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

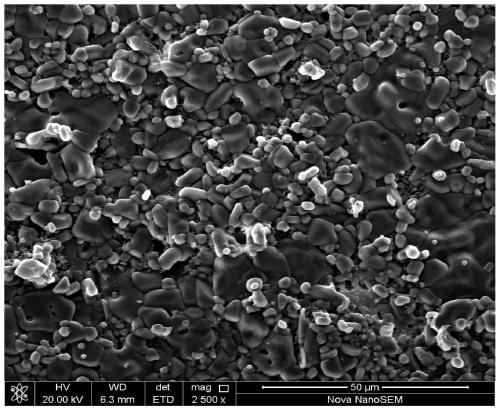

[0056] Using phenolic resin as toughening agent solute and absolute ethanol as solvent to Si 3 N 4 Real-time toughening of the surface layer during ceramic grinding. Si 3 N 4 Ceramics have the advantages of high temperature resistance, corrosion resistance, wear resistance, light density, small thermal expansion coefficient, etc., but due to their high brittleness, they are prone to cracking damage during grinding. Adopt the method of the present invention to Si in the grinding process here 3 N 4 Ceramics are toughened in real time to verify the feasibility of this method. Follow the steps below to implement:

[0057] 1) Use phenolic resin as the solute of the toughening agent, absolute ethanol as the solvent, and prepare the toughening agent according to the volume ratio of the solute to the solvent of 1:6.

[0058] 2) Reaction sintered Si with a size of 80×40×10mm 3 N 4 The ceramic block was fixed on a surface grinding machine, and the toughening agent was coated on...

Embodiment 2

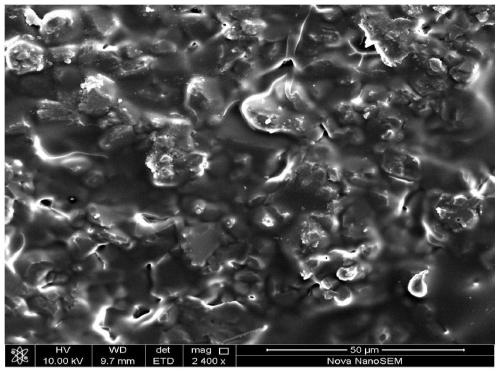

[0065] Using epoxy resin and dioctyl phthalate as toughening agent solute, absolute ethanol as solvent to Si 3 N 4 Real-time toughening of the surface layer during ceramic grinding. Follow the steps below to implement:

[0066] 1) Take epoxy resin and dioctyl phthalate as the toughening agent solute, and dehydrated alcohol as the solvent, prepare the toughening agent according to the volume ratio of solute and solvent 1:8, wherein, epoxy resin and phthalate The mass ratio of dioctyl formate is 1:2.

[0067] 2) Reaction sintered Si with a size of 80×40×10mm 3 N 4 The ceramic block was fixed on a surface grinding machine, and the toughening agent was coated on the edge of the grinding surface of 80 × 10 mm.

[0068] 3) Set the grinding wheel speed of the grinding machine to 2000r / min, the feeding speed to 6m / min, and the grinding depth to a p = 0.02mm. The size of the diamond grinding wheel used is 200×6-20×Φ31.75mm, and the diamond particle size is 80 # .

[0069] 4) G...

Embodiment 3

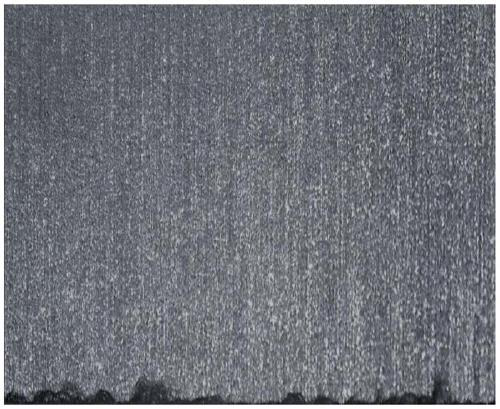

[0074] Using vinyl resin, carboxyl-terminated nitrile rubber as toughening agent solute, and absolute ethanol as solvent to Si 3 N 4 Real-time toughening of the surface layer during ceramic grinding. Follow the steps below to implement:

[0075] 1) Take vinyl resin as toughening agent, carboxyl-terminated nitrile rubber as toughening agent solute, absolute ethanol as solvent, prepare toughening agent according to the volume ratio of solute and solvent 1:5, wherein, vinyl resin and carboxyl-terminated butyl The mass ratio of nitrile rubber is 1:1.5.

[0076] 2) Reaction sintered Si with a size of 80×40×10mm 3 N 4 The ceramic block was fixed on a surface grinding machine, and the toughening agent was coated on the edge of the grinding surface of 80 × 10 mm.

[0077] 3) Set the grinding wheel speed of the grinder to 2000r / min, the feeding speed to 5m / min, and the grinding depth to a p = 0.02mm. The size of the diamond grinding wheel used is 200×6-20×Φ31.75mm, and the diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com