Unit fluidization, high-efficiency gas-saving, blockage control, anti-wear, leading automatic embolism full-pipe conveying system

A conveying system and fluidization technology, which is applied in the field of unit fluidization, high-efficiency, air-saving, blockage, anti-wear, lead-type automatic embolization and full-pipe conveying system, and can solve the problem of reducing the reliability of air-supply action of air-supply components and the service life of air-supply components. , pollution of the air supply air path and air supply components, etc., to achieve the effects of less wear, low conveying flow rate, and reduced air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

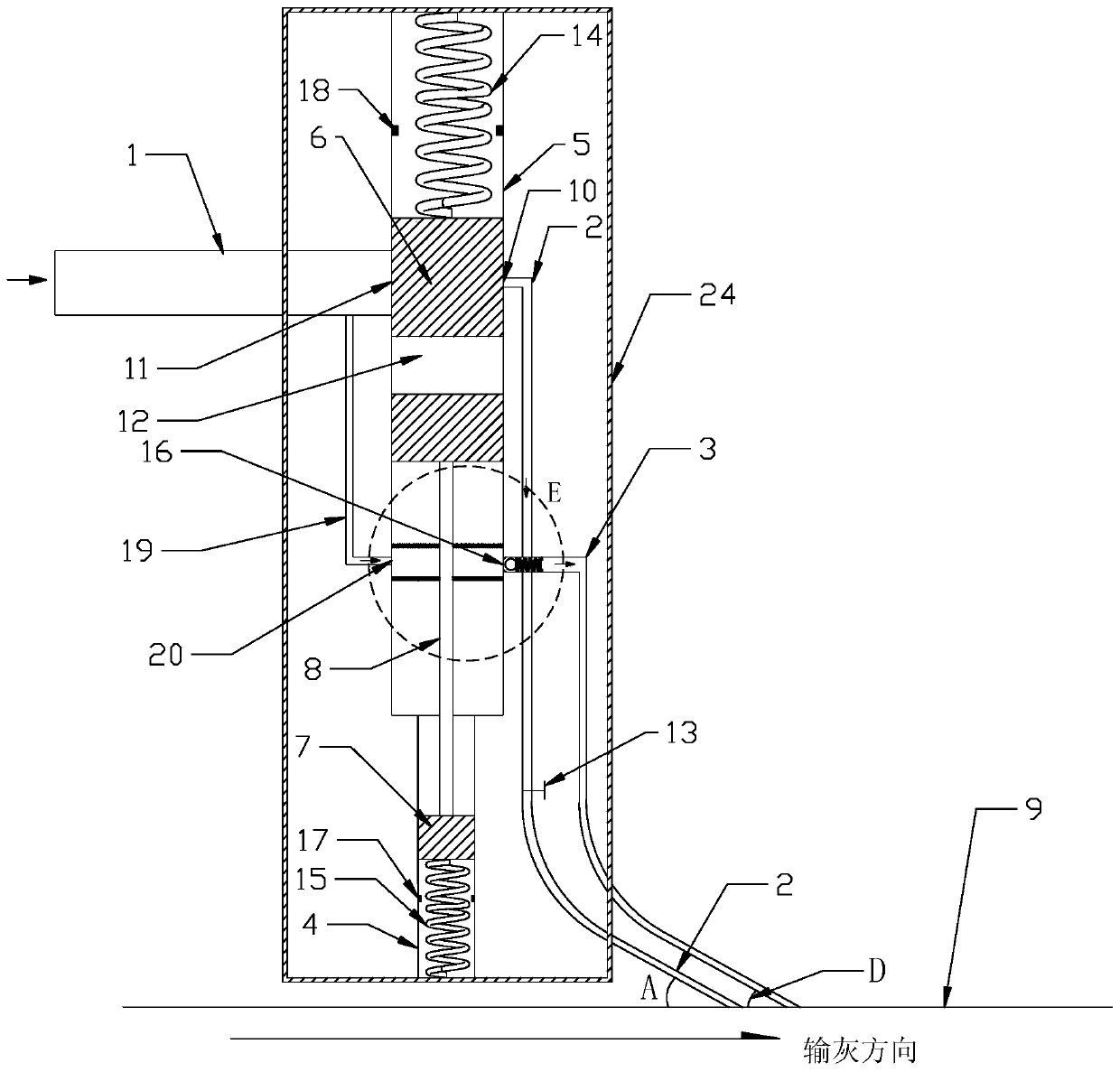

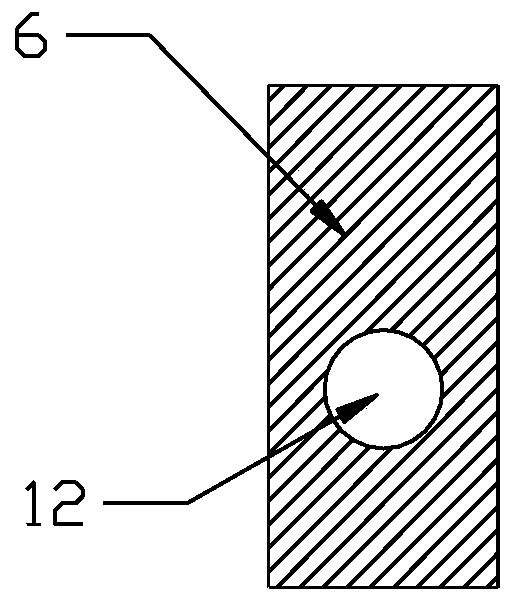

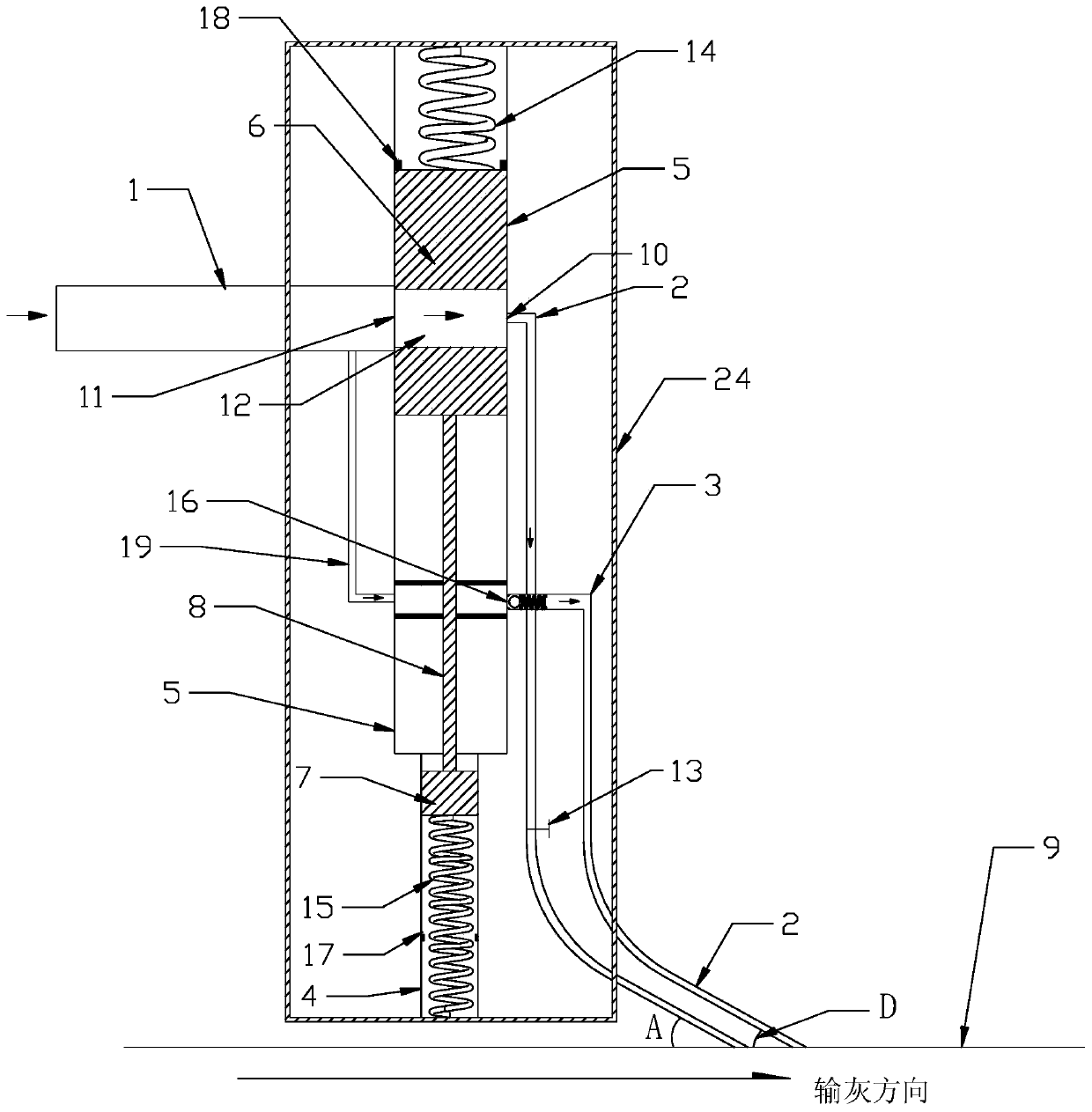

[0035] Such as Figure 1 to Figure 8 As shown, the fluidized high-efficiency gas-saving, blockage-controlling and wear-resistant pre-guided automatic embolism full-pipe delivery system in this embodiment includes an air supply branch pipe 1, an air blowing pipe 2, an overflow pipe 3, a first cylinder 4, a second cylinder 5, and an air guide piston. 6 and a balance piston 7; the first end of the first cylinder 4 is fixedly connected to the second end of the second cylinder 5, the air guide piston 6 is located in the second cylinder 5, and the balance piston 7 Located in the first cylinder 4, the air guide piston 6 and the balance piston 7 are relatively fixedly connected through a piston rod 8, and one end of the overflow pipe 3 is connected to the air guide piston 6 and the balance piston 7. The overflow inlet 16 on the second cylinder 5 between the two is in fluid communication, and the other end of the overflow pipe 3 is in fluid communication with the ash conveying pipe 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com