Capacitive flexible touch sensor based on spherical curved surface polar plate

A tactile sensor and spherical surface technology, applied in the field of sensors, can solve the problems of lack of tangential force detection capability and low detection sensitivity, achieve excellent dynamic response characteristics and detection sensitivity, improve detection sensitivity, good mechanical robustness and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

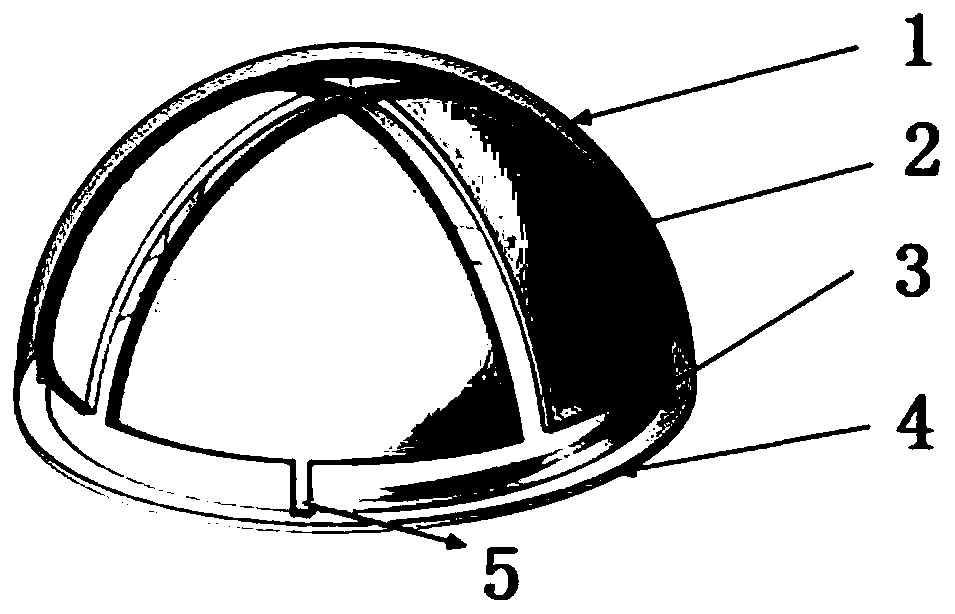

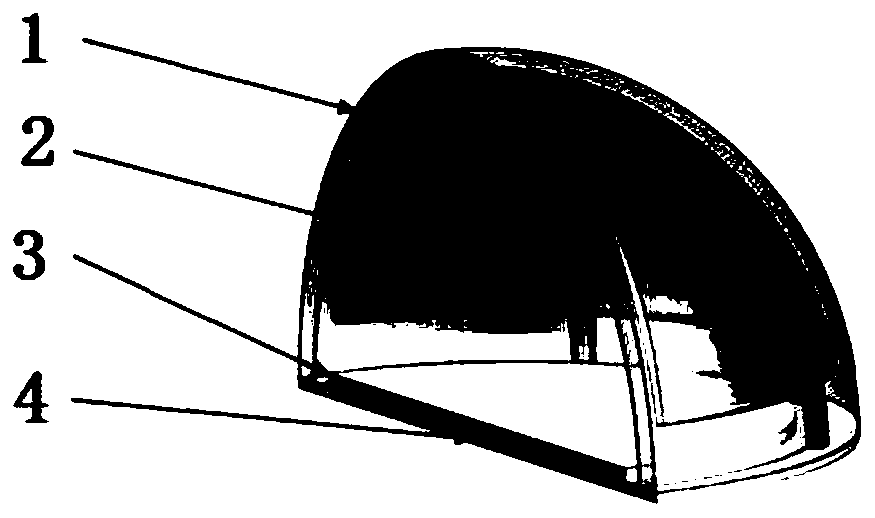

[0049] Embodiment 1 Capacitive flexible tactile sensor based on spherical surface polar plate

[0050] see Figure 1a , 1b , the capacitive flexible touch sensor based on the spherical surface plate provided by the present invention includes: a hemispherical flexible cavity 1, four spherical surface sensing plates 2, a flexible common plate 3, and a flexible substrate 4; wherein, the four The above-mentioned spherical surface induction plates 2 are attached and fixed on the inner wall of the hemispherical flexible cavity 1 at equal intervals, and the central axis of the hemispherical flexible cavity 1 is used as the symmetry line to be symmetrical in pairs, and each spherical surface The induction plates are not in contact with each other, and the bottoms of the four spherical induction plates are provided with electrode leads 5, and the electrode leads 5 are drawn out through the flexible base 4; the flexible common plate 3 is arranged on the flexible base 4, The flexible co...

Embodiment 2

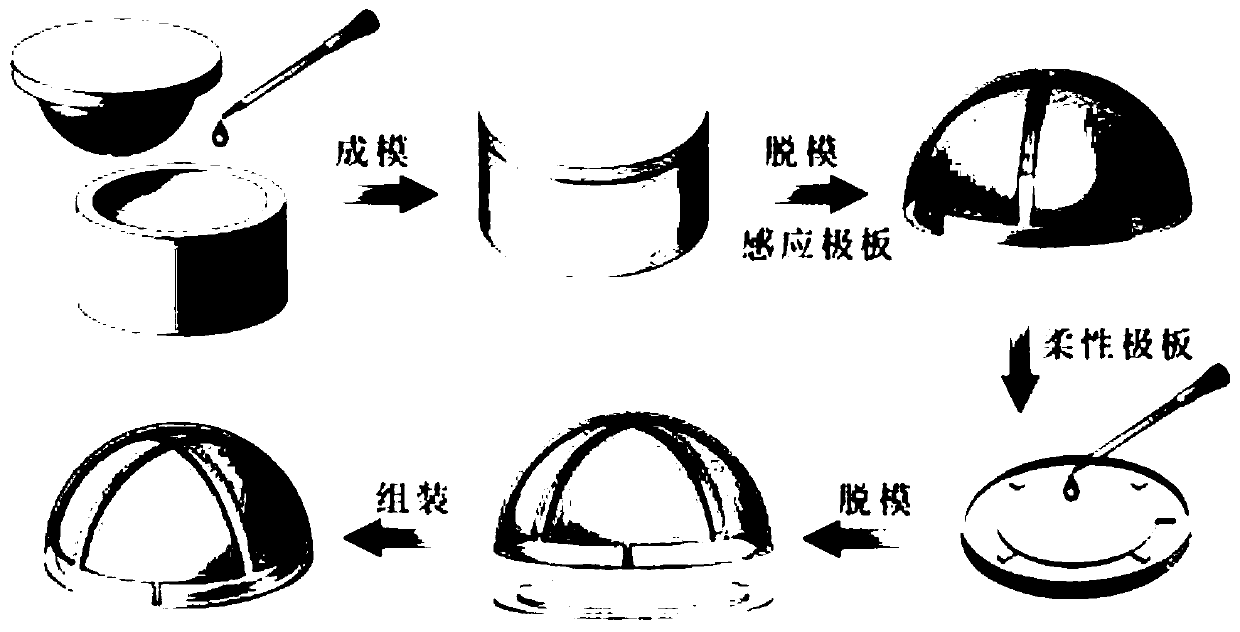

[0055] Embodiment 2 The preparation method of the capacitive flexible tactile sensor based on the spherical surface polar plate

[0056] see figure 2 , a method for preparing a capacitive flexible tactile sensor based on a spherical surface plate provided by the present invention, specifically comprises the following steps:

[0057] Step S1, using three-dimensional modeling software and a 3D printer (Makerbot Replicator 2x, precision 100 μm, the United States) to prepare a mold corresponding to the hemispherical flexible cavity and the flexible substrate in the tactile sensor;

[0058] Step S2, inject silicone rubber into the mold, place in a vacuum drying oven (DZF-6021, Shanghai Suopu Instrument Co., Ltd.), and release the mold after curing at room temperature to obtain the required hemispherical flexible cavity and flexible substrate;

[0059] Step S3, uniformly coating YC-02 type silicone conductive silver glue on the corresponding positions of the hemispherical flexible...

Embodiment 3

[0062] Embodiment 3 Tactile perception method of capacitive flexible tactile sensor based on spherical surface polar plate

[0063] The working principle of the capacitive flexible tactile sensor based on the spherical surface plate can be equivalent to a parallel-plate capacitor with variable plate spacing; first, the functional relationship between the output capacitance and the structural parameters of the capacitive flexible tactile sensor in this paper is analyzed through theoretical calculations. Considering that the plate structure has the characteristics of non-planar and unequal areas, based on the principle of calculus, the spherical surface induction plate capacitor is equivalent to the cascade connection of infinitely many micro capacitors (parallel plate capacitors), and according to the capacitor level Integrate according to the connection rule. Figure 3 is a schematic diagram of the parameter structure of a single spherical surface plate capacitor, as shown in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com