High-light-resistant color change indicating device

A technology of color change indication and light resistance, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problem of narrow and poor applicability. Discoloration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

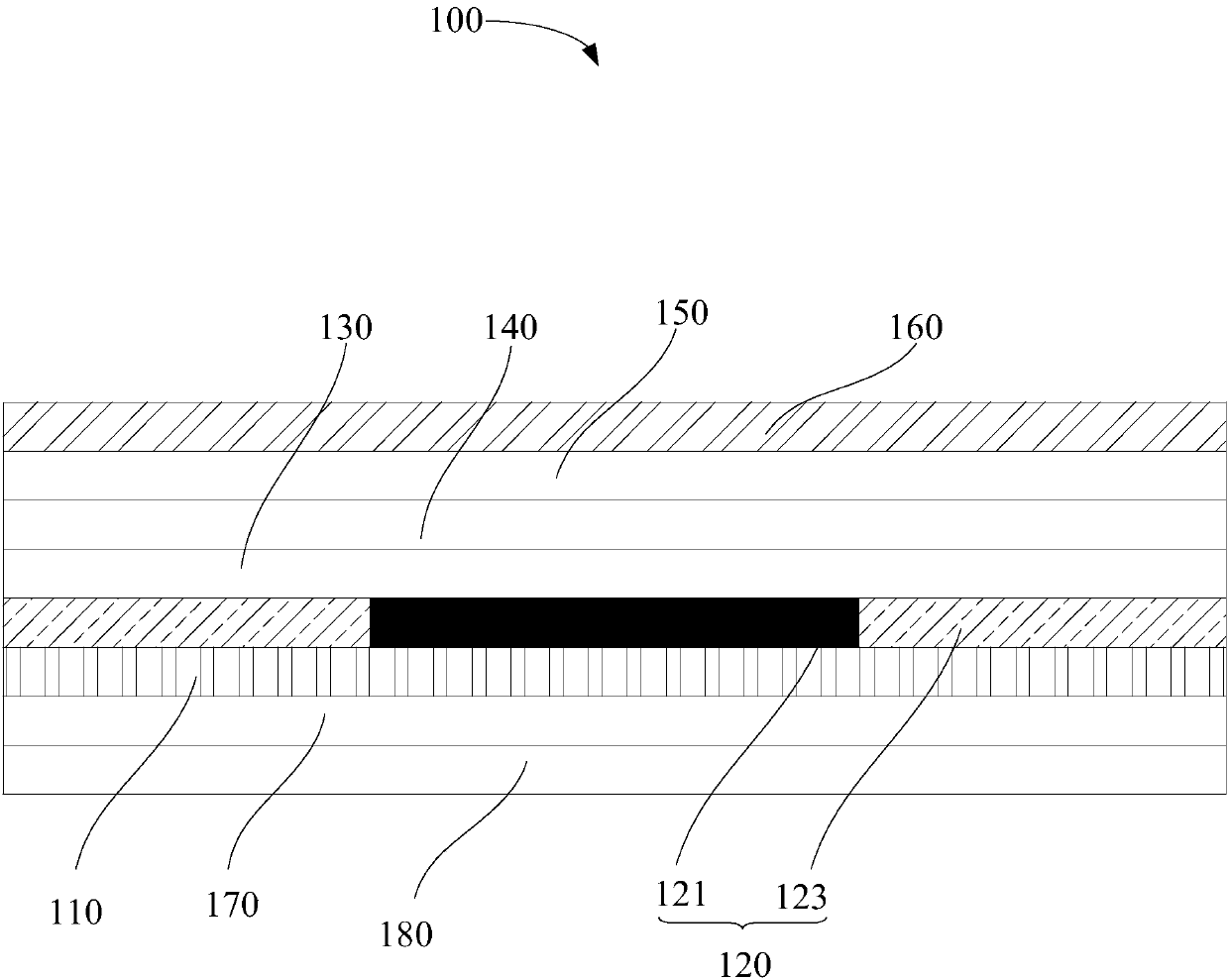

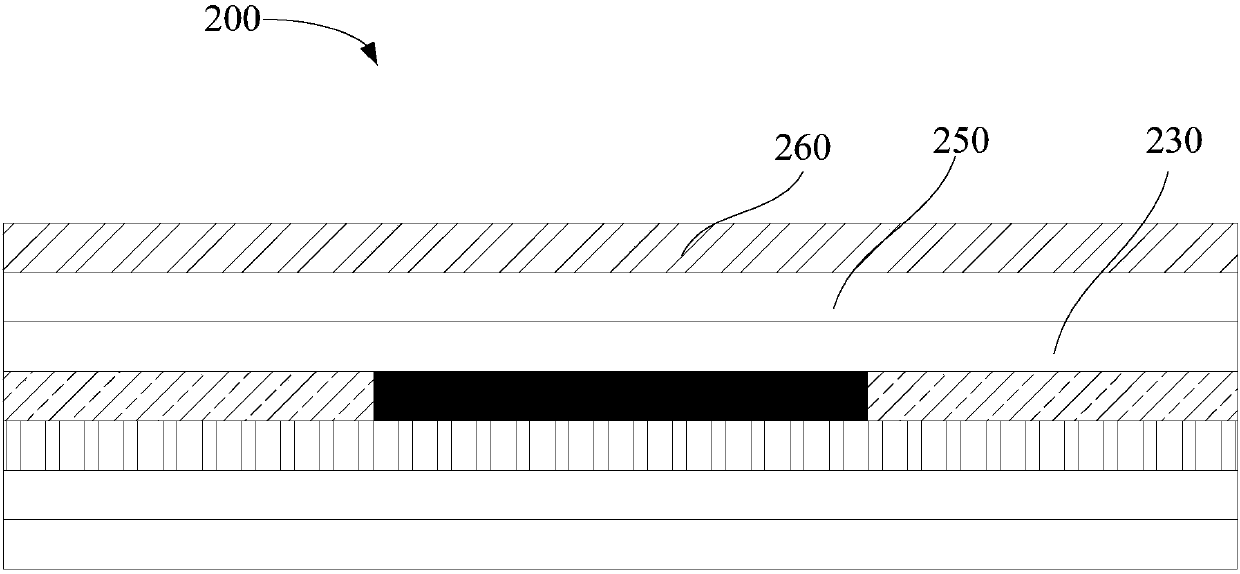

[0049] The structure of the high light-resistant color change indicating device of Example 1 is as follows: figure 2 As shown, it includes a base layer, an indicator layer, a protective layer, an adhesive layer, a barrier layer, an adhesive layer, and a release layer.

[0050] Wherein, the material of the base layer is PET, and the thickness is 0.1 mm.

[0051] The indicator portion is formed by drying the indicator ink after printing, and the indicator ink includes 5 parts of ferrocene, 1 part of magnesium chloride, 30 parts of water and 30 parts of hydroxymethyl cellulose. The indicator portion is a circle with a diameter of 10 mm and a thickness of 0.01 mm. The reference part is a circular ring and is arranged around the indicating part, the inner diameter of the reference part is 12mm, and the outer diameter of the reference part is 20mm. The reference part includes three colors of orange, light orange and light yellow, which respectively provide the starting color, mid...

Embodiment 2

[0059] The structure of the high light-resistant color change indicating device of Example 2 is as follows: figure 2 As shown, it includes a base layer, an indicator layer, a protective layer, an adhesive layer, a barrier layer, an adhesive layer, and a release layer.

[0060] Wherein, the material of the base layer is PET, and the thickness is 0.3 mm.

[0061] The indicating part is formed by drying the indicating ink after printing, and the indicating ink includes 40 parts of cobaltocene, 5 parts of sodium chloride, 70 parts of ethanol and 60 parts of butyl acrylate. The indicator portion is a circle with a diameter of 10mm and a thickness of 1mm. The reference part is a circular ring and is arranged around the indicating part, the inner diameter of the reference part is 12mm, and the outer diameter of the reference part is 20mm. The reference part includes three colors of purple-black, purple, and light purple, which respectively provide the starting color, middle color ...

Embodiment 3

[0069] The structure of the high light-resistant color change indicating device of Example 3 is as follows: figure 2 As shown, it includes a base layer, an indicator layer, a protective layer, an adhesive layer, a barrier layer, an adhesive layer, and a release layer.

[0070] Wherein, the material of the base layer is PET, and the thickness is 0.3 mm.

[0071] The indicating part is formed by drying the indicating ink after printing, and the indicating ink comprises 20 parts of vanadium bismuth, 3 parts of sodium chloride, 40 parts of isopropanol and 40 parts of methyl methacrylate. The indicator portion is a circle with a diameter of 10 mm and a thickness of 0.1 mm. The reference part is a circular ring and is arranged around the indicating part, the inner diameter of the reference part is 12mm, and the outer diameter of the reference part is 20mm. The reference part includes three colors of purple-black, purple, and light purple, which respectively provide the starting c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com