Preparation technology for preserved guava fruit

A production process, guava technology, applied in the confectionery industry, confectionery, food science and other directions, can solve problems such as affecting taste, browning, shrivelling, etc., and achieve the effect of prolonging storage time, increasing sales, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation technology of guava preserved fruit, comprises the following steps:

[0020] (1) Raw material screening: select guavas that are fresh and free from diseases and insect pests at nine maturity levels as raw materials, and remove other guavas that do not meet the requirements.

[0021] (2) Cleaning and cutting: Wash the guava repeatedly with clean water, and use a planer to plan off the outer green skin, then cut it in half and dig out the seed nest, then cut the guava pulp into slices with a thickness of 4mm .

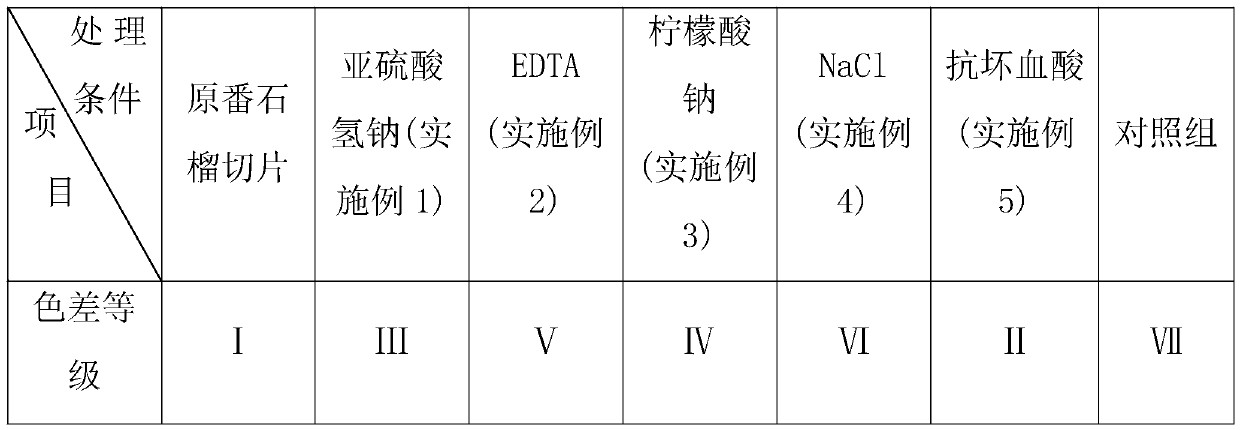

[0022] (3) Color protection and blanching: Put the sliced guava pulp into an aqueous solution of sodium bisulfite with a solubility of 0.1%, soak for 30 minutes, rinse the surface of the pulp with clean water, and then blanch it with hot water at 90°C for 3 minutes Then pick up.

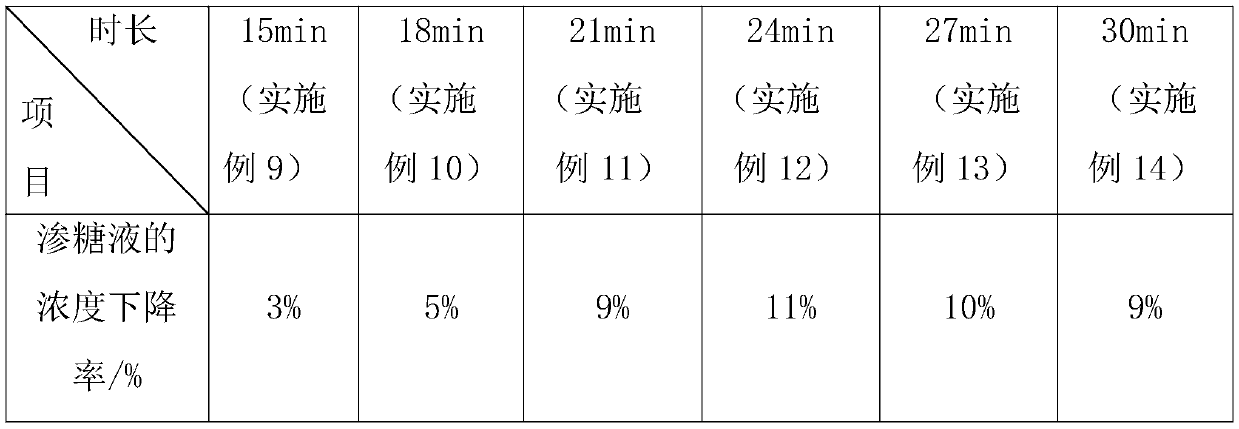

[0023] (4) Vacuum sugar infiltration: the guava slices and ingredients in step (3) are 5%-8% sugar content, CaCl 2 0.2% of citric acid, 0.3% of citric acid, an...

Embodiment 2

[0027] A kind of preparation technology of guava preserved fruit, comprises the following steps:

[0028] (1) Raw material screening: select guavas that are fresh and free from diseases and insect pests at nine maturity levels as raw materials, and remove other guavas that do not meet the requirements.

[0029] (2) Cleaning and cutting: Wash the guava repeatedly with clean water, and use a planer to plan off the outer green skin, then cut it in half and dig out the seed nest, then cut the guava pulp into slices with a thickness of 4mm .

[0030] (3) Color protection and blanching: Put the sliced guava pulp into 0.1% EDTA aqueous solution, soak for 30 minutes, rinse the surface of the pulp with clean water, and then scald it with 90°C hot water for 3 minutes and pick it up .

[0031] (4) Vacuum sugar osmosis: the guava slices and ingredients in step (3) are 5% sugar content, CaCl 2 0.2% of citric acid, 0.3% of citric acid, and the rest of distilled water are poured into th...

Embodiment 3

[0035] A kind of preparation technology of guava preserved fruit, comprises the following steps:

[0036] (1) Raw material screening: select guavas that are fresh and free from diseases and insect pests at nine maturity levels as raw materials, and remove other guavas that do not meet the requirements.

[0037] (2) Cleaning and cutting: Wash the guava repeatedly with clean water, and use a planer to plan off the outer green skin, then cut it in half and dig out the seed nest, then cut the guava pulp into slices with a thickness of 4mm .

[0038] (3) Color protection and blanching: Put the sliced guava pulp into an aqueous solution of sodium citrate with a solubility of 0.1%, soak it for 30 minutes, then rinse the surface of the pulp with clean water, and then blanch it with hot water at 90°C for 3 minutes scoop up.

[0039] (4) Vacuum sugar osmosis: the guava slices and ingredients in step (3) are 5% sugar content, CaCl 2 0.2% of citric acid, 0.3% of citric acid, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com