Water treatment system applicable to offshore oilfield platform and treatment method of water treatment system

A water treatment system and offshore oilfield technology, applied in multi-stage water treatment, natural water body treatment, degassed water/sewage treatment, etc., can solve the problems of marine ecological environment impact, inability to expand production, and large footprint , to achieve the effect of reducing the residence time, improving the processing capacity, and improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

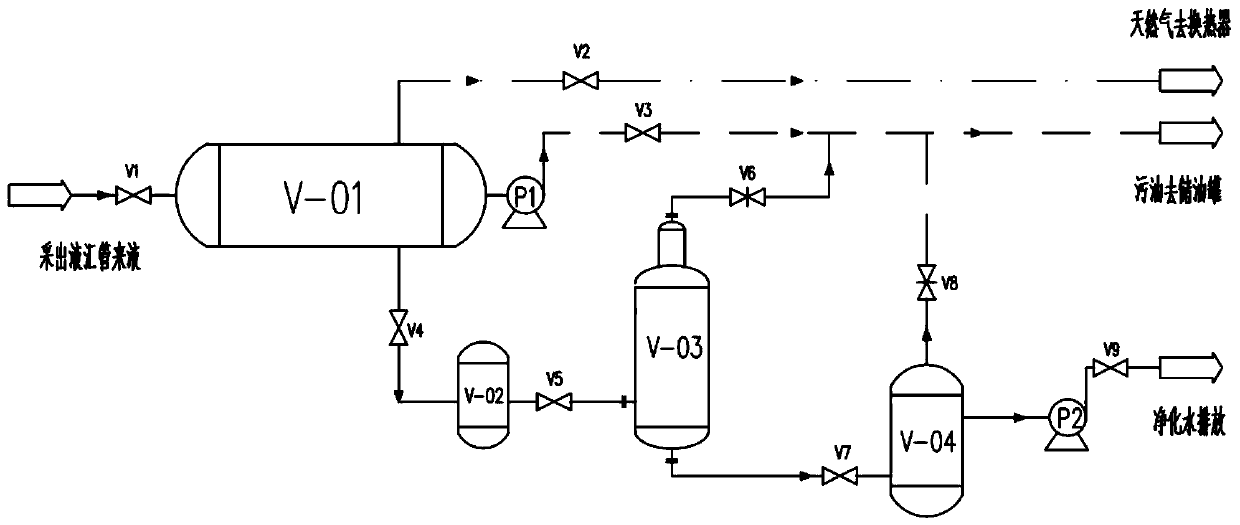

[0034] The water treatment method and system of the present invention are adopted in the production water treatment of an offshore oil field that needs to be expanded, such as figure 1 As shown, it is a schematic flow chart of an offshore platform production water treatment method using a vertical deep coalescing degreaser. The production water treatment system of the offshore platform includes V-01 production separator, V-02 pre-filter, V-03 deep coalescing oil remover, V-04 fiber ball filter, P1 sewage oil transmission booster pump, P2 Production of water transmission booster pumps, V1 ~ V9 valves.

[0035] The bottom-hole production liquid enters the production separator V-01 after passing through the valve V1, and the separated gas is discharged to the heat exchanger outside the system through the gas phase outlet through the valve V2 for heat exchange treatment; the dirty oil passes through the oil phase outlet and then passes through the dirty oil The transmission boost...

Embodiment 2

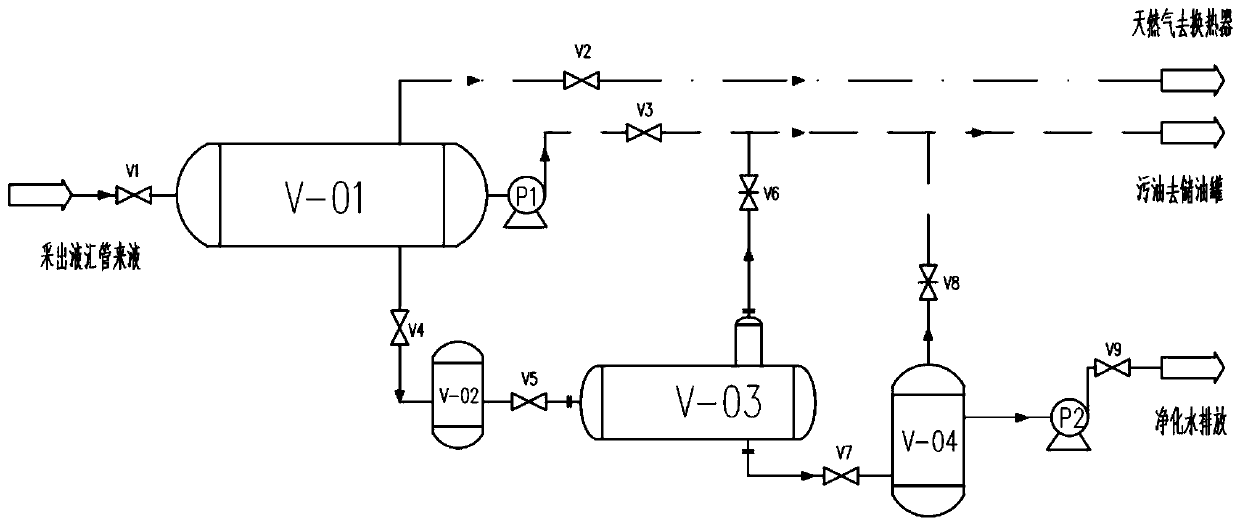

[0041] Such as figure 2 As shown, it is a schematic flow chart of an offshore platform production water treatment method using a horizontal deep coalescence degreaser. All the other contents are as in Example 1.

[0042] On the basis of the original production water treatment process, the system uses a high-efficiency deep coalescence degreasing device to replace the inclined plate degreaser and air flotation separator; uses a fiber ball filter to replace the walnut shell filter; the space resources of the process system remain unchanged Under normal circumstances, the processing capacity is 1.3 to 1.8 times that of the traditional method. While ensuring that the production water is discharged up to the standard, it has the advantages of small space requirement, stable separation performance, large operating flexibility, and low operating cost, which can meet the current expansion needs of offshore platforms.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap