Laser activable high temperature resistant thermoplastic composition and preparation method thereof

A technology of laser activation and composition, which is applied in the field of thermoplastic compositions, can solve the problems of low tensile strength, low punching fracture strength, and high water absorption of materials, and achieve the effects of improving dispersion, improving solubilization, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned laser-activatable high-temperature-resistant thermoplastic composition, which includes the following steps;

[0035] S1: Drying, drying the thermoplastic high temperature resistant resin at 100-160°C;

[0036] S2: Premixing, according to the weight percentage, PAI, PI or organic titanium liquid surface modifier; 0.60%-3.00% and redox graphene (RGO): 0.60%-0.90% were stirred at 50°C for more than 6 hours, Get component 1.

[0037] S3 granulation, according to weight percentage, LDP additive: 8.00%-12.00%; thermoplastic high-temperature resistant resin: 80.50%-88.50%; rubber solubilizing polymer: 1.00%-3.00%; high-temperature resistant oxidant: 0.20%-0.50 %; Toner or high dielectric material: 0.10%-1.00% mixed with component 1 and granulated at 240-300°C, wherein the L / D value of the granulation equipment is controlled above 25, and the screw speed is not greater than 95RPM;

[0038] S4: pell...

Embodiment 1

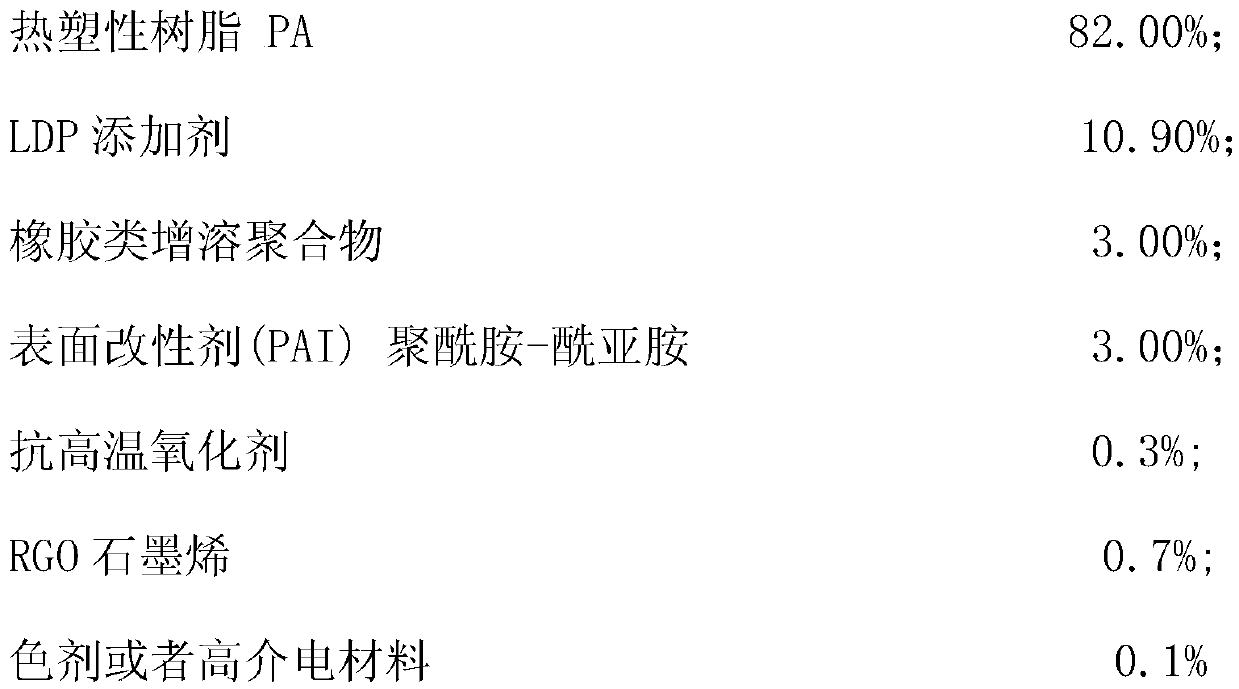

[0042] The thermoplastic composition comprises the following components according to weight percentage:

[0043]

[0044] The preparation method of described thermoplastic composition, comprises the following steps:

[0045] S1: drying, drying the thermoplastic high temperature resistant resin at 120°C;

[0046] S2: premixing, according to the weight percentage, PAI liquid surface modifier; 3.00%; redox graphene (RGO): 0.70% at 50 ° C for more than 6 hours to obtain component 1.

[0047] S3: Granulating, according to weight percentage, LDP additive: 10.90%; thermoplastic high temperature resistant resin: 82.00%; rubber solubilizing polymer: 3.00%; high temperature resistant oxidant: 0.30%; colorant or high dielectric material: 0.10% % and component 1 are mixed and granulated at 240-300°C, wherein the L / D value of the granulation equipment is 25, and the screw speed is 95RPM to granulate to obtain the finished product;

[0048] S4: pelletizing, the pelletizing speed is 40-...

Embodiment 2

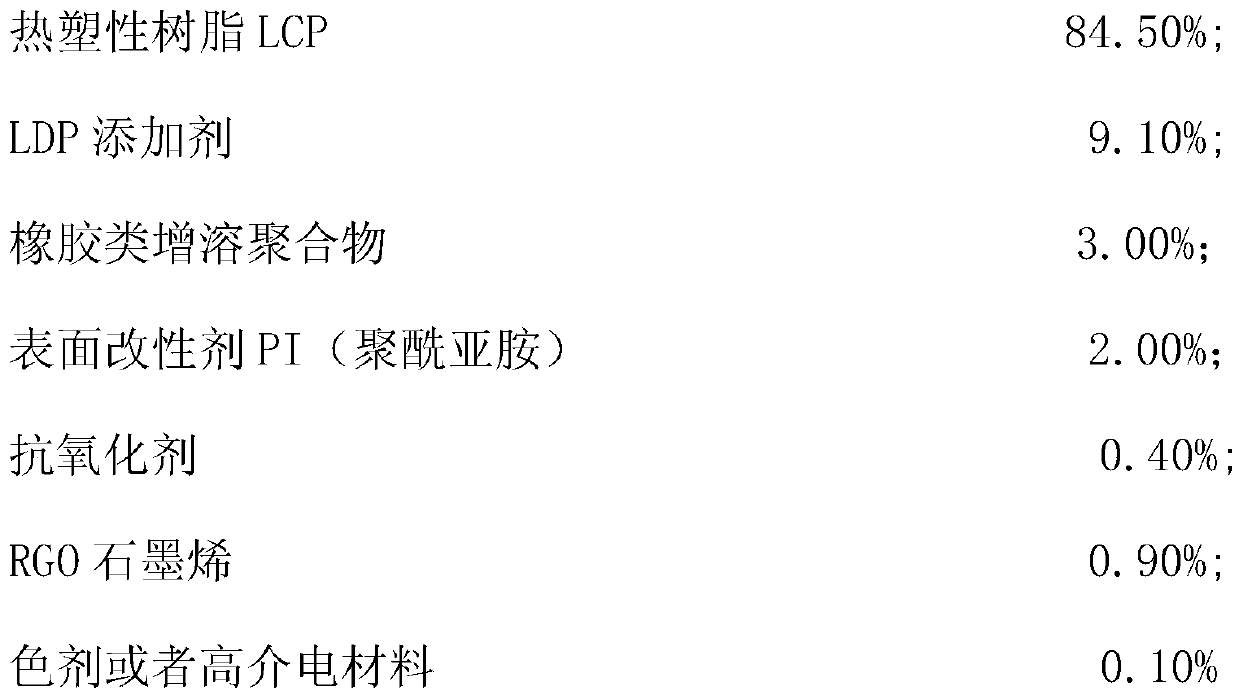

[0051] The thermoplastic composition comprises the following components according to weight percentage:

[0052]

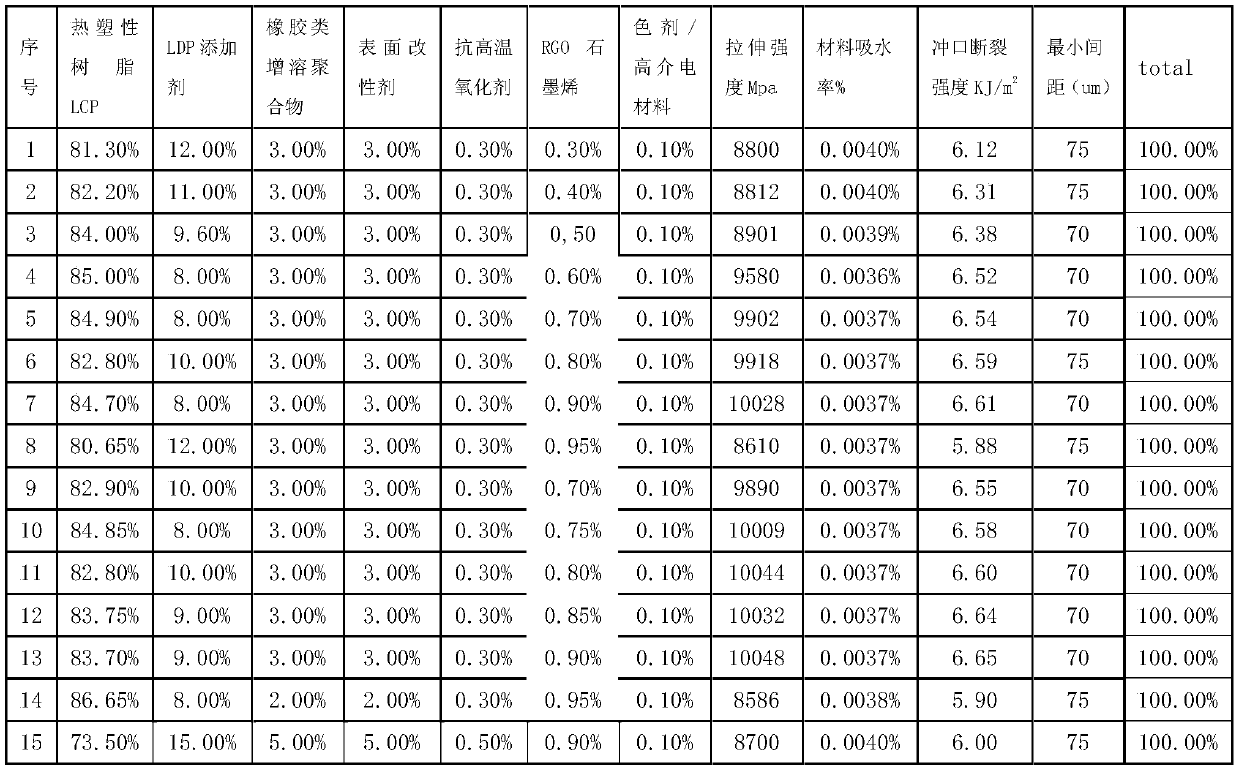

[0053] The following lists more embodiments and their corresponding effects in the form of a table:

[0054]

[0055] The preparation method of described thermoplastic composition, comprises the following steps:

[0056] S1: drying, drying the thermoplastic high temperature resistant resin at 140°C;

[0057] S2: Premixing, according to the weight percentage, PI liquid surface modifier; 2.00%; redox graphene (RGO): 0.90% was finely mixed at 50°C for more than 6 hours to obtain component 1.

[0058] S3: Granulating, according to weight percentage, LDP additive: 9.10%; thermoplastic high temperature resistant LCP resin: 84.50%; rubber solubilizing polymer: 3.00%; high temperature resistant oxidant: 0.40%; colorant or high dielectric material: 0.10% mixed with component 1 and granulated at 240-300°C, wherein the L / D value of the granulation equipment is 25, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com