High-thermal-conductivity conductive adhesive prepared from nano-silver modified carbon nanotubes and preparation method of conductive adhesive

A technology of carbon nanotubes and nanosilver, which is applied in the direction of conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of high brittle cost of thermal conductive adhesives, poor printability of pastes, and low thermal conductivity. Achieve the effects of improving dispersion performance, improving viscosity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

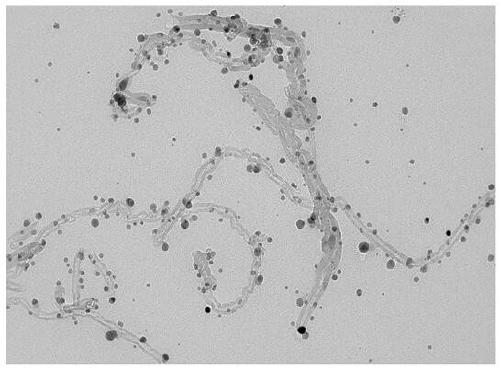

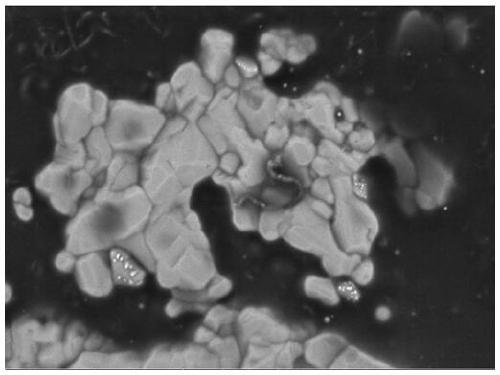

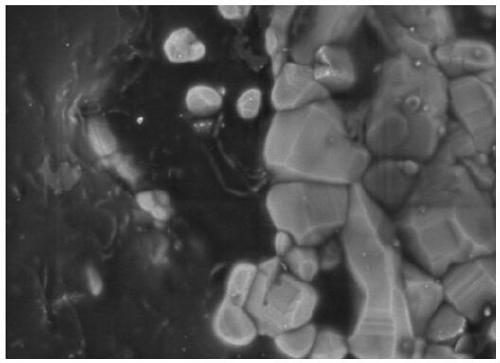

Image

Examples

Embodiment 1

[0028] The nano-silver-modified carbon nanotubes are used to prepare high thermal and conductive adhesives, which are prepared from the following raw materials: 20 g of resin carrier, 65 g of silver powder, and 1 g of nano-silver-modified carbon nanotubes.

[0029] The preparation method of the nano-silver modified carbon nanotubes for preparing high thermal conductivity and electrical conductivity adhesive, the specific steps are as follows:

[0030] Step 1, preparation of nano-silver modified carbon nanotubes:

[0031] Add 10 g of carbon nanotubes into 50 mL of ethanol solution, disperse them with ultrasonic waves for 20 minutes under ice bath conditions, then add 10 g, 1 mol / L sodium dodecyl sulfate solution, and continue the supernatant dispersion for 1 h to obtain a suspension of carbon nanotubes. The carbon nanotube suspension is centrifuged and washed to prepare activated modified carbon nanotubes;

[0032] Add the obtained activated modified carbon nanotubes to 50g, 1...

Embodiment 2

[0038] The nano-silver-modified carbon nanotubes are used to prepare high thermal and conductive adhesives, which are prepared from the following raw materials: 35g of resin carrier, 80g of silver powder, and 5g of nano-silver-modified carbon nanotubes.

[0039] The preparation method of the nano-silver modified carbon nanotubes for preparing high thermal conductivity and electrical conductivity adhesive, the specific steps are as follows:

[0040] Step 1, preparation of nano-silver modified carbon nanotubes:

[0041]Add 15 g of carbon nanotubes into 100 mL of ethanol solution, and disperse them with ultrasonic waves for 25 minutes under ice bath conditions, then add 15 g, 1 mol / L sodium dodecyl sulfate solution, and continue the supernatant dispersion for 2 hours to obtain a suspension of carbon nanotubes. centrifuging and washing the suspension of carbon nanotubes to prepare activated modified carbon nanotubes;

[0042] Add the obtained activated modified carbon nanotubes t...

Embodiment 3

[0047] The nano-silver-modified carbon nanotubes are used to prepare high thermal and conductive adhesives, which are prepared from the following raw materials: 25g of resin carrier, 75g of silver powder, and 4g of nano-silver-modified carbon nanotubes.

[0048] The preparation method of the nano-silver modified carbon nanotubes for preparing high thermal conductivity and electrical conductivity adhesive, the specific steps are as follows:

[0049] Step 1, preparation of nano-silver modified carbon nanotubes:

[0050] Add 20 g of carbon nanotubes into 50 mL of ethanol solution, and disperse them by ultrasonic waves for 30 minutes in an ice bath, then add 20 g of 1 mol / L sodium dodecyl sulfate solution, and continue the supernatant dispersion for 1.5 h to obtain a suspension of carbon nanotubes. centrifuging and washing the suspension of carbon nanotubes to prepare activated modified carbon nanotubes;

[0051] Add the obtained activated modified carbon nanotubes to 60g, 1mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com