An energy-saving and environment-friendly organic light-emitting element

An organic light-emitting element, energy-saving and environmentally friendly technology, applied in electrical components, semiconductor devices, electro-solid devices, etc., can solve the problem of not being able to optimize electronic conduction loss and organic interface loss at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

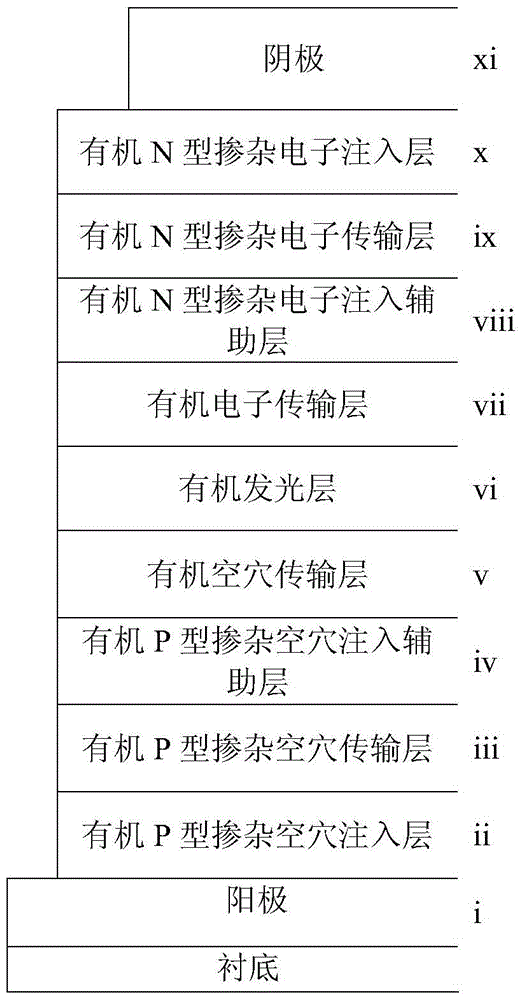

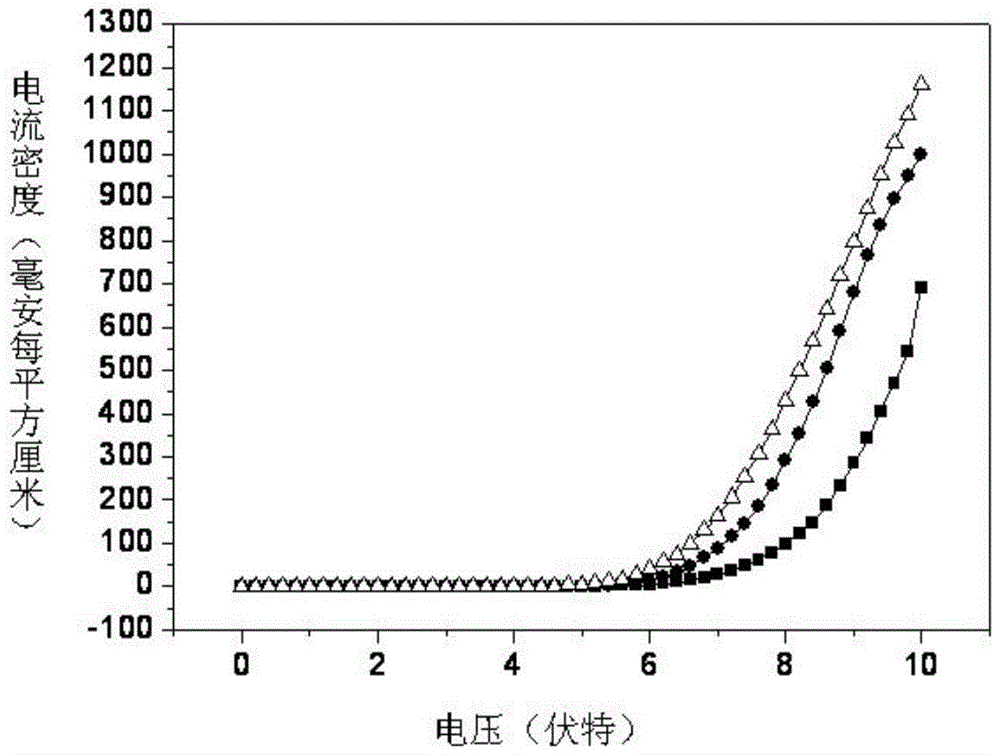

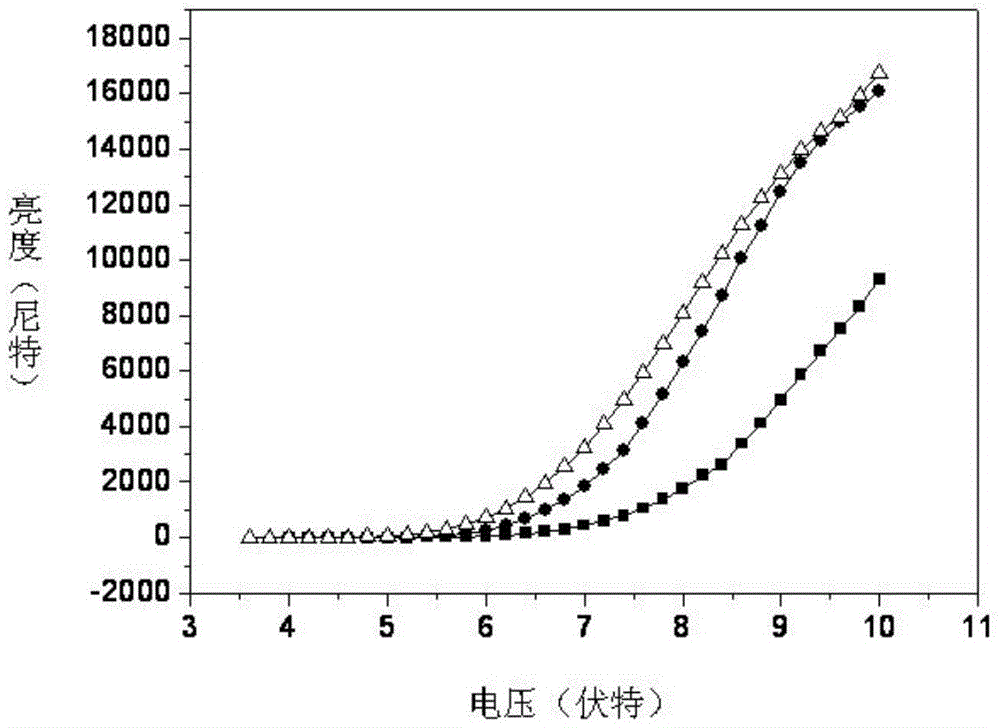

[0059] The preparation structure is ITO / CBP:ReO 3 =1:0.01 Thickness 1nm / m-MTDATA:F 4 TCNQ=1:0.01 Thickness 10nm / CBP:ReO 3 =1:0.01 Thickness 1nm / CBP Thickness 10nm / Alq3 Thickness 60nm / Bphen Thickness 5nm / Bphen:Cs=1:0.01 Thickness 5nm / NTCDA:LCV=1:0.01 Thickness 20nm / Bphen:Cs=1:0.01 Thickness 5nm / Al Organic light-emitting diodes with a thickness of 100nm.

[0060] The organic light-emitting diode is composed of a layer of ITO anode on a glass substrate, a layer of CBP:ReO with a thickness of 1 nm deposited on the ITO anode. 3 Thin film organic P-type doped hole injection layer, one layer deposited on CBP:ReO 3 m-MTDATA with a thickness of 10 nm on the thin-film organic P-type doped hole-injection layer: F 4 TCNQ thin film organic P-type doped hole transport layer, one layer deposited on m-MTDATA:F 4 1nm-thick CBP:ReO on TCNQ thin-film organic P-type doped hole-transport layer 3Thin film organic P-type doped hole injection auxiliary layer, one layer deposited on CBP:ReO 3 A...

Embodiment 2

[0101] The preparation structure is ITO / TCTA: MoO 3 =1:1 thickness 20nm / MeO-TPD:ReO 3 =1:1 thickness 200nm / TCTA:MoO 3 =1:1 thickness 20nm / TCTA thickness 50nm / Alq3 thickness 60nm / Bphen thickness 20nm / Bphen:Cs=1:0.5 thickness 20nm / NTCDA:LCV=1:0.1 thickness 300nm / Bphen:Cs=1:0.5 thickness 20nm / Al Organic light-emitting diodes with a thickness of 100nm.

[0102] The organic light-emitting diode is composed of a layer of ITO anode on a glass substrate, a layer of TCTA: MoO deposited on the ITO anode with a thickness of 20nm 3 Thin film organic P-type doped hole injection layer, one layer deposited on TCTA: MoO 3 MeO-TPD:ReO with a thickness of 200 nm on a thin-film organic P-type doped hole-injection layer 3 Thin-film organic P-type doped hole transport layer, one layer deposited on MeO-TPD: ReO 3 20 nm thick TCTA:MoO on thin-film organic P-type doped hole-transport layer 3 Thin film organic P-type doped hole injection auxiliary layer, one layer deposited on TCTA: MoO 3 TCTA ...

Embodiment 3

[0130] The prepared structure is Au 20nm / CBP:ReO 3 =1:0.01 Thickness 1nm / m-MTDATA:F 4 TCNQ=1:0.01 Thickness 10nm / CBP:ReO 3 =1:0.01 Thickness 1nm / CBP Thickness 10nm / Alq3 Thickness 60nm / Bphen Thickness 5nm / Bphen:Cs=1:0.01 Thickness 5nm / NTCDA:LCV=1:0.01 Thickness 20nm / Bphen:Cs=1:0.01 Thickness 5nm / Al Organic light-emitting diodes with a thickness of 100nm.

[0131] The organic light-emitting diode is composed of a layer of Au anode with a thickness of 20 nm on a glass substrate, a layer of CBP:ReO with a thickness of 1 nm deposited on the Au anode 3 Thin film organic P-type doped hole injection layer, one layer deposited on CBP:ReO 3 m-MTDATA with a thickness of 10 nm on the thin-film organic P-type doped hole-injection layer: F 4 TCNQ thin film organic P-type doped hole transport layer, one layer deposited on m-MTDATA:F 4 1nm-thick CBP:ReO on TCNQ thin-film organic P-type doped hole-transport layer 3 Thin film organic P-type doped hole injection auxiliary layer, one layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com