Efficient transmission mechanism of water turbine

A technology of transmission mechanism and water turbine, which is applied in the direction of machines/engines, engine components, reaction engines, etc., can solve the problems of not being able to change output power according to needs, not being able to make good use of water resources, and unfavorable normal operation of equipment, so as to achieve convenience Output power, good for voltage regulation, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

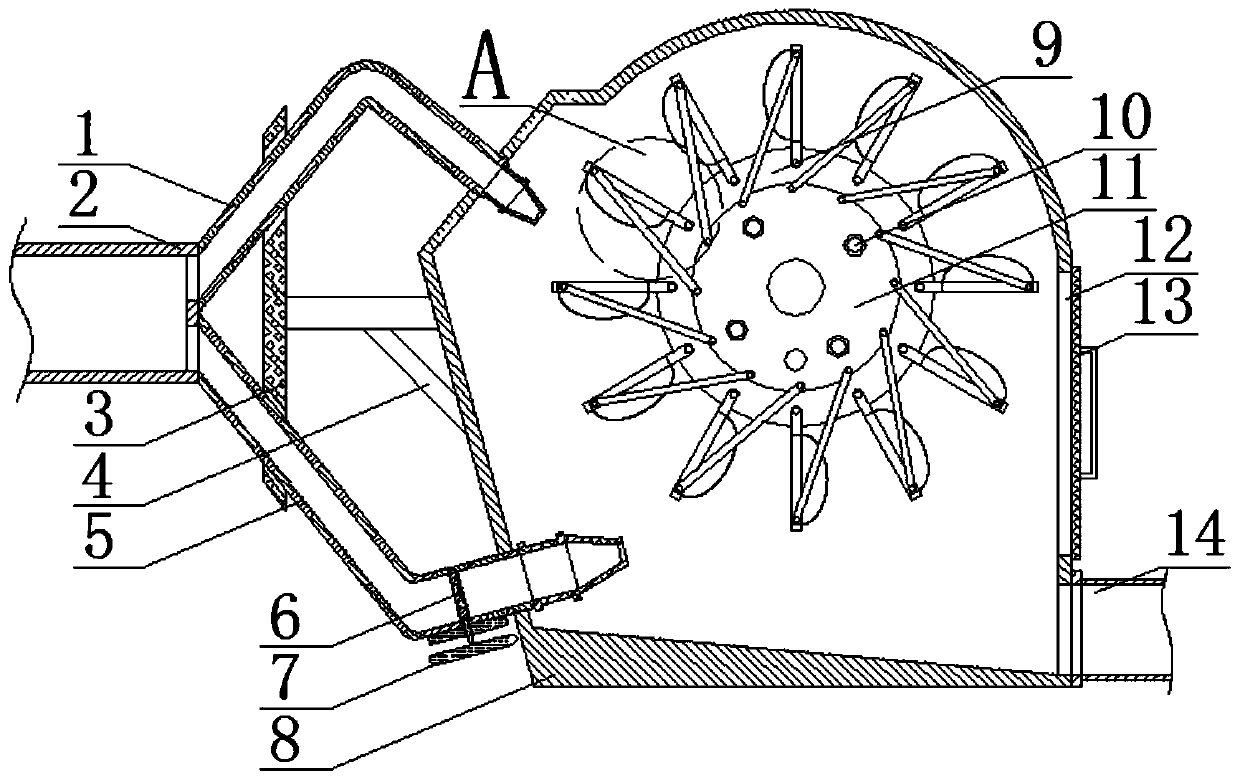

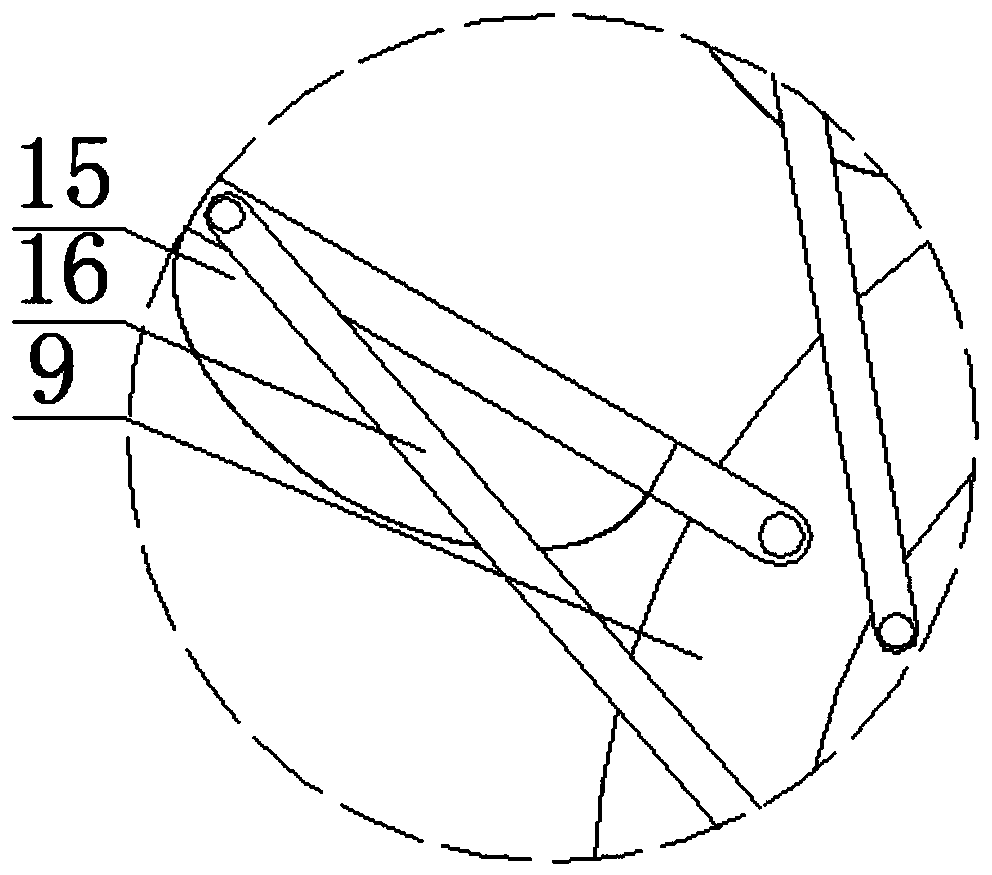

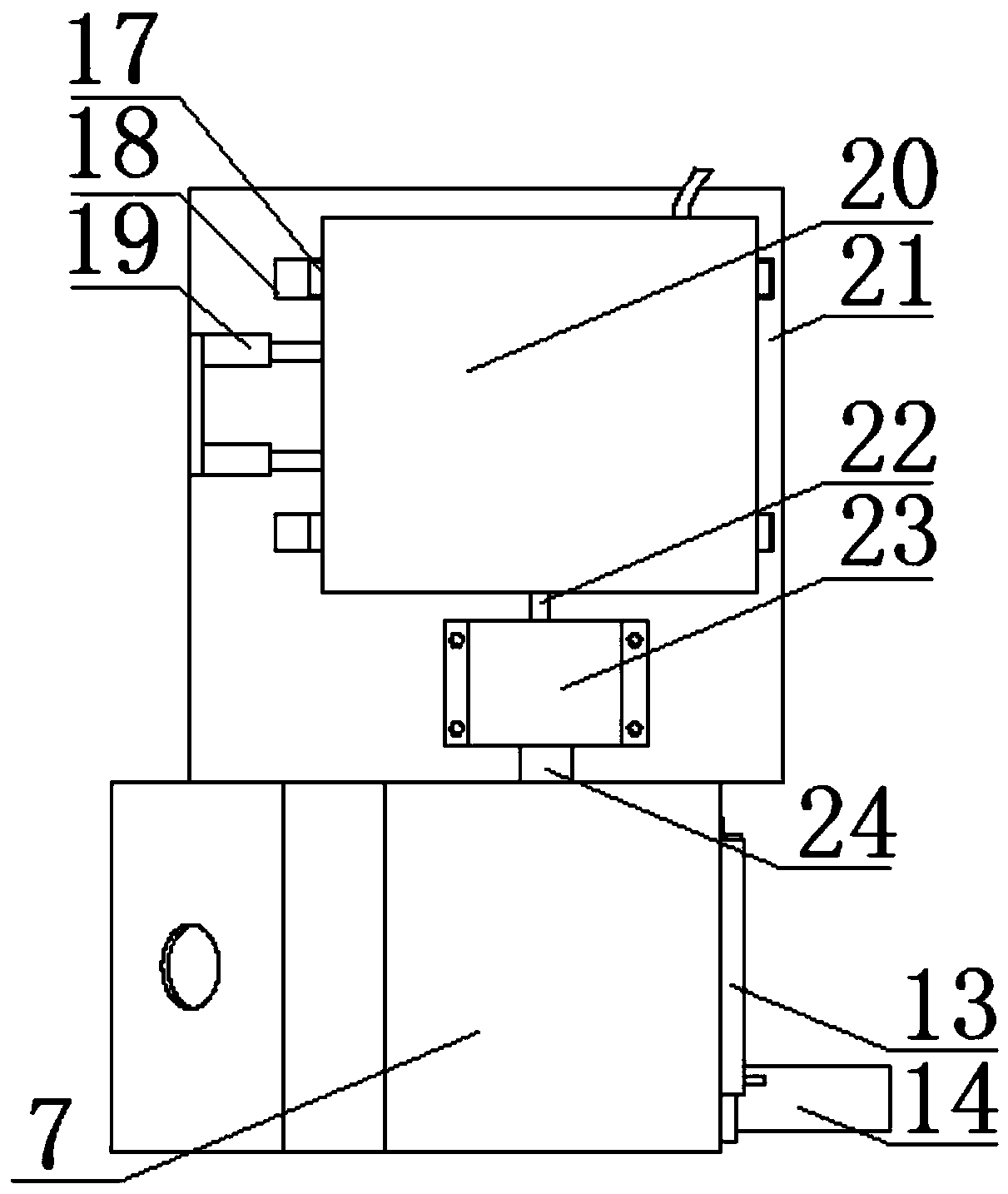

[0037] refer to figure 1 , 3 , 4, 5, 6, 8, a high-efficiency transmission mechanism of a water turbine, including a first housing 8, the bottom of the first housing 8 is inclined, so as to facilitate the flow of accumulated water, and then facilitate discharge, which is convenient for excessive accumulated water. To affect the rotation of the first turntable 9, a bottom plate 21 is fixed on one side of the lower end of the first housing 8, a second rotating shaft 24 is rotatably sleeved on one end side wall of the first housing 8, and a second rotating shaft 24 is fixed on one end of the second rotating shaft 24. A turntable 9, and the first turntable 9 is located in the first housing 8, the first turntable 9 is equidistantly provided with a plurality of rotating plates 15, one side of the first case 8 is provided with a water delivery device, and the water delivery device Corresponding to the rotating plate 15, so that the water impacts the rotating plate 15 conveniently, an...

Embodiment 2

[0051] refer to figure 1 , 2 , 3, 4, 5, 6, 7, 8, a high-efficiency transmission mechanism of a water turbine, including a first housing 8, the bottom of the first housing 8 is arranged obliquely, so as to facilitate the flow of accumulated water, and then facilitate discharge and accumulation Too much water will affect the rotation of the first turntable 9. A bottom plate 21 is fixed on one side of the lower end of the first casing 8, and a second rotating shaft 24 is sleeved on one end side wall of the first casing 8. The second rotating shaft 24 One end is fixed with a first turntable 9, and the first turntable 9 is located in the first casing 8, a plurality of rotating plates 15 are arranged at equal intervals on the first turntable 9, and a water delivery device is installed on one side of the first casing 8. , the water delivery device corresponds to the rotating plate 15, so that the water impacts the rotating plate 15 conveniently, and then can drive the first rotating...

Embodiment 3

[0067] refer to figure 1 , 3 , 4, 5, 6, 8, a high-efficiency transmission mechanism of a water turbine, including a first housing 8, the bottom of the first housing 8 is inclined, so as to facilitate the flow of accumulated water, and then facilitate discharge, which is convenient for excessive accumulated water. To affect the rotation of the first turntable 9, a bottom plate 21 is fixed on one side of the lower end of the first housing 8, a second rotating shaft 24 is rotatably sleeved on one end side wall of the first housing 8, and a second rotating shaft 24 is fixed on one end of the second rotating shaft 24. A turntable 9, and the first turntable 9 is located in the first housing 8, the first turntable 9 is equidistantly provided with a plurality of rotating plates 15, one side of the first case 8 is provided with a water delivery device, and the water delivery device Corresponding to the rotating plate 15, so that the water impacts the rotating plate 15 conveniently, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com